how to make a wooden double bed

We spend a third of our lives in bed, so we want our bed to look modern, stylish and, ideally, absolutely stunning! Of course, it is expensive, but the best way not to go broke is to make a double bed out of wood with your own hands . Doubt your abilities? Believe me, you can make furniture yourself that will compete with store models, and at the same time you will significantly save your money.

There are not many presented here, only 25 examples of how to make a wooden double bed with your own hands, but this is enough to decide on the design. There are classic double beds, but I like the modern style - make a bed on a platform , beautiful and economical. If you want something unusual, see the instructions on how to make a floating bed , today it is very fashionable. Each example with step-by-step photos and a link to the source.

Preparatory work

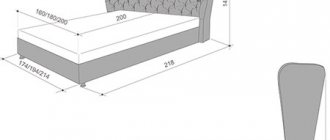

First of all, you need to decide on the size of the mattress, because the dimensions of the bed will depend on it. You also need to think about the design of the future structure, its shape, height, and size of the backs. Then you should calculate the amount of materials required. It is imperative to prepare drawings and indicate the dimensions of all elements of the future bed. If desired, you can use ready-made drawings, adapting them to your own needs.

To work you will need the following tools:

- electric drill, drills;

- jigsaw;

- construction knife;

- hammer;

- scissors;

- Screwdriver Set;

- furniture stapler, staples for covering the frame or paint brushes (depending on the preferred method of decorative processing of the product).

The mother also needs to purchase materials. If the base of the bed is made of wood, then for a standard mattress measuring 2000 by 1800 mm you will need:

- 2 boards 2070 by 300 mm for the sides;

- 2 boards 1810 by 300 mm for the front and rear walls;

- slats 20 by 80 mm for making lamellas;

- a sheet of plywood (it will help strengthen the bottom of the product);

- self-tapping screws, confirmations, metal corners for connecting structural elements;

- stain, varnish, wood glue, putty, upholstery materials for processing and decorating the finished product.

It should be remembered that when determining the size of the frame, it is necessary to add 10-15 mm to each side of the mattress. The best material for making the base is a well-dried calibrated board with a thickness of at least 30 mm. Its strength is sufficient to withstand heavy loads.

Point No. 4: puttying and sanding the frame

Puttying is used only if the frame is painted with opaque paints. There are special putties for wood; these compounds cover all the cracks and joints, resulting in a monolithic, even box.

Sanding the frame is done with fine sandpaper. There is one caveat: when painting, varnishing or oiling, after the initial sanding, the first layer of the composition is applied. When it dries, micro-lint will rise on the wood, so this lint is removed once with fine sandpaper, and then subsequent layers of decor follow.

The box is painted after sanding.

Point No. 3: main frame

| Illustrations | Recommendations |

| Array . To create the frame, a board with a thickness of 30–40 mm and a width of 200 mm is used. Only dry planed wood is used. At the final stages of arrangement, light sanding is allowed to correct minor defects. | |

Mounting holes.

| |

| Chamfer . The chamfer is removed from all frame boards and lightly sanded with sandpaper. | |

| Assembly . The ends of the boards are smeared with wood glue, joined and twisted with self-tapping screws. | |

| Stripping . As assembly proceeds, excess glue will protrude; it is advisable to wipe it off immediately. |

Point No. 2: double bed with lifting mechanism

With the help of such a mechanism, the under-mattress shield is raised and the owners have free access to the voluminous linen box located in the lower part of the structure.

There are 2 types of lifting mechanisms - spring and gas lift. The first option is cheaper, but it is less reliable and durable, plus steel springs can stretch and creak over time. A gas piston is a little more expensive, but it is much more reliable.

It is better to install mechanisms with gas pistons on the lifting system of a double bed.

Material selection

Question of choice

Materials for making a bed:

- Metal corner.

- Profile or round pipe.

- Solid wood.

- Plywood.

- Chipboard.

- Pallets.

The above materials can be used either individually or in combination. Thus, a metal bed can be equipped with wooden backs, and a plywood product is assembled on a frame made of timber. There can be many options, and you can understand this in more detail by reading the article.

How to make a headboard yourself

Imitation of headboard on wall paint

Paint is one of the simple and inexpensive options for a DIY bed headboard. On the wall where the bed will be installed, the shape of the head of the bed is drawn with paint; at this stage, you can get creative and draw a three-dimensional drawing.

Then the bed frame is placed against the wall. This method looks very original in the interior.

Board with perforation in the form of a headboard

A perforated panel is an interesting idea for a DIY headboard that you can make at home in a few minutes.

To do this, you need to select a suitable perforated panel and wrap it around all edges with bright tape. If the panel is adjusted to the size of the bed, then the sawn ends should be sanded and varnished, otherwise the raw edges will cling to the bed linen.

Timber headboard

In order to make a headboard from timber, you need to prepare wooden blanks of the same size, with a length equal to the height of the headboard. The bars are attached to the wall in the intended way: vertically or horizontally. You can leave a distance between the pieces, so the design will look more airy. The bars are coated with varnish or paint.

Note!

DIY furniture made from pallets (140 photos) - step-by-step master class with diagrams and drawings, design ideas

DIY coffee table - manufacturing guide with a full description of the steps, choice of materials (120 photo ideas)

Do-it-yourself laundry basket (130 photo ideas): step-by-step master class for making it yourself, choice of materials, design options

Upholstered headboard

It’s also easy to make a soft headboard at home. To work, you will need to draw a diagram of the headboard on a furniture board. You can use a variety of back designs: rectangular, round, oval, everything will depend on the intended design. For upholstery you will need thick fabric or artificial leather, as well as a layer of thin foam rubber.

Buttons can be used to imitate a carriage tie on fabric. The shield is covered with a layer of thin foam rubber, then covered with fabric or leather on top. The ends of the fabric and foam rubber are secured to the back of the base using a furniture stapler. Then buttons are sewn on the front side of the back, in a checkerboard pattern, the indentations created on the fabric look like a carriage tie stitched in production. Next, all that remains is to secure the soft backrest to the wall.

Upholstered headboard on wood panels

This method of making a headboard for a bed looks very original. In order to make such a headboard with your own hands, you first need to attach wooden panels to the wall according to the size of the bed. This can include ordinary wooden panels, furniture facades and even old doors. Next, the wall panels are decorated with soft elements.

In this case, ordinary sofa pillows are very suitable, they need to be placed in removable pillowcases and hung on wooden boards with the help of braid. The main condition is that the pillow covers are removable, since they will have to be washed often.

The final stage is decoration

The facade of the final product is often decorated with false doors - an overhead element that is part of the decoration, onto which handles are attached. Do not use mirrors in such beds under any circumstances, as they are not designed for such loads and may soon crack.

Even the simplest folding bed design can fit into any room interior.

This will also affect the weight of the structure being lifted, which may affect the durability of the mechanism. Be sure to install the legs into the pre-drilled holes and magnetic latches. Now the work is completed, and the new decoration of your interior is completely ready for your relaxation.

A single folding bed can be installed in the front room, and no one outside will even think about its presence, since it will be disguised as a closet.

Decorative elements

We have already talked about soft headboards, but this is far from the only way to decorate a homemade bed. Now on the market you can make to order or buy ready-made decorative elements for covering beds. This can be a small fragment or a whole carved wooden plate.

This decor looks luxurious, the only problem is that handmade work costs serious money. Alternatively, such plates can be ordered from a furniture workshop and made not from natural wood, but from MDF. There are machines that mill patterns in 3D projection.

Carved decor on a homemade bed looks luxurious.

Wood preparation

Before starting work, the wood must be cut to size, the ends and corners sanded, and possible defects and irregularities removed. This point should not be neglected, because otherwise wooden beds will look like an awkward home product.

The procedure is as follows:

- Cut all the bars and boards according to preliminary markings. Sand the cut areas, clean the corners and the entire surface to make it smooth.

- Treat all structural elements with a wood primer before assembly so that there is protection even in hard-to-reach places and fasteners.

- Impregnations and pigments for wood are used if it is necessary to enhance the structure of the fibers. They prevent rotting processes, strengthen the base and increase the service life of the finished product.

- If smoothness and uniformity are important, it is better to use stains. They should be applied in two layers with a brush or nap roller before final installation of the entire structure.

- Varnishing is carried out at the final stage of installation. Be sure to wait a while for the surface to gain strength and for the unpleasant odor to disappear; Furniture can only be used after its final demise.

To prevent the bed from creaking, when assembling the frame and installing other structural elements, the joints must be treated with wood glue, which will strengthen the fastening and provide the necessary “layer.” If this is not done, squeaking cannot be avoided.

Wood processing

Primer

Wood impregnation

Applying paint

Varnished

Legs

Making legs yourself is the easiest step in the entire construction process.

Whole production process:

- the prepared beam with a cross-section of 10x10 cm must be cut into 6 bars 10.5 cm long;

Preparing for future legs

- fastening is carried out to the support bars;

- for the strength of the frame, two additional legs are attached under the central support, at a distance of 50 cm from the edges of the frame;

- They can be given any shape for decoration. You can cut one of the corners at a distance of about 3 cm from the bottom, at an angle of 45 degrees, as in the photo;

- at the end of the work it is necessary to sand all sides.

Recording all created elements:

- as mentioned above, the legs are attached to the supporting boards of the frame. To do this, use 60 mm self-tapping screws. You need to spend at least two on each leg;

This is what the legs look like inside

- holes are pre-drilled with a drill, a drill whose diameter coincides with the cross-section of the screws.

The legs are attached to the frame

. Before screwing in screws, you should first drill holes, which will reduce the risk of splitting the boards.

What style does it suit?

A bed made of timber looks harmonious in different interiors. It fits the following areas:

- country.

It would be appropriate to use a round beam here. This interior requires a combination of cozy and warm shades. It is recommended to lay a checkered bedspread on the assembled bed. The headboard of the product can be carved or solid. The bed should stand on massive legs; - modern Here it would be appropriate to build a sleeping place from laminated veneer lumber;

- loft. The easiest way to make such products on your own is from timber. It is recommended to place the bed opposite a brick wall. Other pieces of furniture should also be rough and slightly uncouth to create harmony;

- classicism. The bed should have a high back and strict shapes. A bed in this style is characterized by the presence of a high back, and the height of its frame is located at a distance of 70 cm from the floor. It is better to decorate the headboard of the product with reliefs: triangles, squares and other ornaments. It is better to choose a dark color for the product, closer to black. An excellent choice as building materials would be oak timber;

- Provence For this, the product should be painted white and covered with a colored blanket;

- high tech. The product must be characterized by unusual geometric shapes;

- eclecticism. The product should be massive and decorated with a huge amount of textiles. A calm and neutral blanket is laid on the bed. Decorative pillows should be scattered over the entire surface.