Unfortunately, today there are no cheap beds made from natural boards for sale, and this is despite the fact that our country has the highest wood reserves in the world. Few compatriots can afford to buy a real bed made of wood, beautiful and large, and completely exclusive. The solution is to do it yourself. This is not to say that it is easy and simple, but if you wish and follow the instructions exactly, everything will definitely work out.

DIY wooden bed: drawings and assembly

How to decide on a design

Among the structures most used for self-production are:

- A frame made of edged boards and bars is the cheapest and easiest to assemble frame. Does not require special skills or expensive tools;

- A frame made of square metal pipes of various cross-sections is used less frequently than a wooden structure, as it requires welder skills and a good welding machine.

When choosing a particular frame design, the following factors should be taken into account:

- Dimensions and weight of the mattress - when using a large and heavy mattress (for example, 160x200 cm), the design should include various reinforcements and the use of more reliable and durable fastening elements;

- The height of the future structure - the bed, together with the mattress placed inside its frame, should have a height at which it would be comfortable for its owner to sit on it and just as easily get up;

- The presence of built-in drawers - if you plan to place pull-out drawers for bedding or other things under the bed, then this should be taken into account when planning the height of the frame.

In most cases, all the requirements for this furniture are met by structures made of wooden edged boards and bars.

Choosing a size

What will be the height

Decide whether there will be boxes

Required Tools

Depending on the material chosen, certain tools will be required to work with it.

For working with metal

- Electric welding machine.

- Bulgarian.

- File.

- Metal brush.

- Electric drill.

- Roulette.

For working with wood

- Jigsaw. If the product is made of boards, you can get by with a hacksaw.

- Screwdriver.

- Electric drill.

- Roulette.

- Construction corner.

- Pencil.

- Plane.

- Chisel.

- Grinder machine.

As for consumables, we’ll talk about this separately when considering this or that model.

Design

Designing a bed frame consists of the following steps:

- Choosing a place where the bed will be located - this piece of furniture should be located in the room in such a way as not to interfere with the movement of people or the opening of entrance doors or cabinet doors. The bed should not be placed close to heating devices, radiators, or windows;

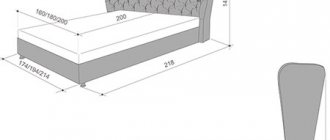

- Determining the dimensions of the future structure. To do this, take into account the dimensions of the mattress, convenience for people of non-standard height, and the availability of free space for installation. At this stage, the dimensions of the future structure are determined, the number and location of amplifiers and other supporting elements are provided;

- Frame drawings are made using simple computer programs or manually - linear dimensions are drawn up in the form of a visual drawing.

One of the simple graphic editors is the Graphite utility - an intuitively simple and understandable program that allows you to create easy-to-read, high-quality drawings. The last stage of design is especially important - drawing up a drawing. The result of the assembly depends on a correctly made and well-readable drawing. All sizes and locations of frame parts must be clearly visible, adjacent inscriptions and numbers must not merge.

Practical advice

We have given a description of the technology for making a wooden bed that is average in complexity and reliability. Load-bearing nodes can be connected in several ways.

Table. Methods for connecting load-bearing nodes

| Mounting type | general characteristics |

| Traditional method of joining individual pieces of furniture. The most complex and the most durable. There is a wide variety of such connections; they differ in shape, number and location of the spines. |

| This fastener significantly speeds up the assembly process, and if you have at least a little experience in carpentry, the bed can be assembled in one day. |

| As independent fasteners, dowels are rarely used during bed manufacturing due to insufficient strength. But they have proven themselves well as additional fasteners. |

Decide for yourself which method to use, but the main selection criterion should always be the reliability of the design. Remember that a tree's linear dimensions are constantly changing due to fluctuations in relative humidity. At the slightest weakening of the load-bearing units, the bed begins to creak; no amount of external design beauty can compensate for such a deficiency.

Preparation of materials

In order to independently build a bed frame for a standard mattress measuring 1400x2000mm, you need the following materials:

- Dry edged pine or spruce board: 200×30×2000 mm – 2 pcs; 200×30×1400 mm – 3 pcs;

- Pine slats: 50×10×1380 mm – 15 pcs;

- Planed pine block: 50×50×2000 mm – 3 pcs; 50×50×700 mm – 2 pcs; 50×50×500 mm – 2 pcs; 50×50×300 mm – 1 pc.

All bars and boards must have a moisture content of no more than 10%, a healthy surface, free of falling knots and rot. In order to completely prevent deformation of the material, it is first left for several days in the room where the structure made from it will be located.

Materials

The required fastening elements are:

- Self-tapping screws for plasterboard, wood with rare threads 3×30, 4.5×40 mm;

- Fastening metal furniture corners sizes: 70×60 mm, 20×15 mm, 35×80 mm;

- Wooden furniture dowels 8×35 mm.

Wood species

You can make a wooden bed from different types of wood:

pine trees

This material is in demand due to its presentable appearance and high technical characteristics. This product will delight you not only with its beautiful texture, but also with its pleasant pine aroma. Products that have been well sanded and varnished are highly resistant to the formation of fungi and do not rot;- oak _ This wood is considered elite. It is distinguished by its luxurious appearance, environmental friendliness, and the ability to create patterns and ornaments on the product;

- beech _ Such beds are distinguished by their original cut patterns, durability and strength. Beech models look noble and fit classic motifs;

- birch trees This type of wood is easy to process, has a high level of strength and elasticity, and is attractive.

Attention : when choosing wood, you should base it on what kind of bed model you need.

To make a wooden product look aesthetically pleasing, but not cost too much, you should know some secrets :

- for decoration and frame it is worth taking expensive material (oak);

- for making legs, cheaper wood (pine) is suitable;

- and for the slats that will be located inside the product, you can choose the simplest option (birch).

Build process

A do-it-yourself bed frame is made like this:

- The headboard is assembled using the long ends of two boards 200×30×1400 mm. holes are drilled. The end surfaces and dowels inserted into the holes are treated with PVA glue and tightly connected;

- A rectangular frame frame is assembled from 2 boards measuring 200×30×2000 mm, 1 board 200×30×1400 mm and a headboard using corners 70×60 mm;

- Holes are drilled in 2 long bars 50x50x700 mm and the ends of the headboard. The headboard and legs are connected using dowels, which are inserted into drilled holes, and PVA glue;

- The long front legs are also attached to the main frame using self-tapping screws screwed through pre-drilled holes in the folds of the 70x60 mm corners;

- In a similar way, the rear legs made of 50x50x500 mm bars are attached to the frame;

- 2 bars measuring 50x50x2000 mm are attached to the long sidewalls using corners 35x80 mm. A third block of the same size is attached in the middle of the frame to the two end walls using 20x15 mm corners. In the middle of the bar, also using a corner, an additional leg made of a 50x50x300 mm bar is installed;

- 25 slats 50x10x1380mm are attached to the fixed bars at equal distances, thereby obtaining the bottom of the frame;

- The frame bottom slats are additionally connected with three long strips using a construction stapler.

The resulting frame, after fastening all the parts, requires minimal processing.

Connecting the elements of the box

We install longitudinal bars

We strengthen the frame with wooden blocks

We fasten the legs

Making a base from lamellas

Decorating the bed

If you set out to do something unusual, then you can find a lot of options for designing a bed in a wide variety of styles - from classic to vintage or modern. But the easiest one to start with is painting the frame. To do this you will need stain and varnish. It is not necessary to use a primer - you need to remember that all work with toxic substances will have to be done indoors, so it is advisable to keep it to a minimum. The stain will highlight the texture of the wood, the varnish will smooth the surface and add shine. You can also use special paint that imitates various types of wood. This method will not only decorate the frame, but will also give it a more impressive look. You can upholster the bed with fabric; for this you will need material, foam rubber, a construction stapler and staples.

Advice! When painting, it is better to use matte varnish. It will hide imperfections in the wood and will collect less dust and be scratched.

You might be interested to know why foam mattresses are in demand?

Final processing

At the final stage, the bed base (frame) made in this way goes through the following stages of final processing:

- Grinding - using a grinding machine and a set of sandpaper, the surface of all parts of the frame is processed. It is preferable to use centrifugal grinders with a special container for collecting large sawdust generated during surface treatment;

- Sealing cracks and pits – cracks and pits formed during sanding are sealed with a special putty compound that is matched to the color of the wood. After the putty has hardened, the surface is sanded again;

- Application of stain – to protect wood from moisture and mold, acrylic or wax stains should be used. They are applied using a wide brush in several layers. The advantages of such stains are that they dry quickly enough, do not cause smudges or streaks, highlight the wood texture well, and have a uniform tone over the entire application surface;

- Applying several layers of varnish - after the stain has dried, apply 2-3 layers of transparent waterproof varnish. In order to hide all surface imperfections that remain even after sanding, it is better to use matte varnishes that can disguise small scratches and chips.

By learning how to quickly and easily make a bed frame with your own hands, you can not only save money on the purchase of this furniture, but also acquire useful skills in assembling such structures. In addition, unlike most beds made from chipboard or MDF, a homemade bed made from wood will last several times longer.

Sanding furniture

Repairing cracks

Cover with stain

Applying varnish

Requirements for a master

To make a bed, several conditions must be met, and all of them are equally important; the absence of at least one of them causes an unsatisfactory result. In this case, it is much better not to start work at all. What criteria must a home furniture maker meet?

- Have practical experience in carpentry work. Don’t flatter yourself with the thought that 2-3 articles read will make you a master; theory can never provide the knowledge and skills that can be acquired in practice. You must make independent decisions in difficult situations, feel the tool, not be afraid of woodworking machines, etc.

- Have tools and equipment. Do not think that the quality of handmade work is superior to the quality of mechanical processing. You will never be able to get the same smooth, clean, and smooth surfaces as with a four-sided router, circular saw, or sander. You must have a minimum list of woodworking equipment.

To make wooden furniture you need appropriate equipment - Have a great desire and free time. Even experienced masters are sometimes disappointed, but you shouldn’t just tune in to a minor key. Prepare for problems, do not retreat when they arise, but analyze the reasons for their occurrence and make every effort to solve them.

- Have material resources. They are not so large, but for a good bed you need to purchase lumber of at least first grade, use only high-quality paints and varnishes.

High-quality lumber is not cheap

If you have positive answers to these questions, then you can start making the bed.