One of the most important elements in bedrooms is the bed. The most common are beds made of wood or chipboard panels. Metal beds are not so popular, since the choice of models is not very wide and many of them require a soft metal mesh instead of a mattress (sleeping on such a bed is very harmful and even dangerous for the spine). But you can still make a good metal bed with your own hands. It will be much cheaper than a custom product. But making a metal bed takes a lot of time, especially if there is no experience in carrying out such work. By preparing for work and purchasing the necessary tools, you can master the production much faster.

Difficulties at work

Making an iron bed is a responsible, slow and complex process. Is it easy to do it yourself? Everyone decides for themselves based on their abilities and skills. To complete this knowledge, some knowledge is required. Creative mood. You need to start small - get lessons from an experienced blacksmith or ask for help in this matter from a knowledgeable person. Because it is very likely that something will go wrong. Trying to create your own is the easier option. In addition, you must have at least the simplest necessary equipment. The main difficulty lies in the preparation of components and their processing. All the necessary diagrams can be taken from the Internet. The main thing is a little patience and self-confidence.

But not always and not according to all parameters it is possible to choose exactly what you need.

Sizing

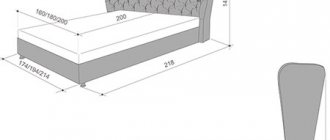

Before starting work, you need to decide on the future dimensions. This requires a clear understanding of where the bed will be and who will sleep in it. In the case of modernizing an apartment or room, you can move away from the usual stereotypes and find a new place for it.

Making an iron bed is a responsible, slow and complex process.

There are standard types of beds: single, double, one-and-a-half. It should be remembered that the sleeping place should be 30 cm longer than the height of the person who is going to sleep in it. Typically the length is 2 m, but can vary from 191 cm to 213 cm.

Some knowledge required.

You also need to consider the width. So, depending on the type, the width will have the following value:

- single - 91cm;

- double – 137 cm;

- one and a half - 99 cm.

You need to start small - get lessons from an experienced blacksmith or ask for help in this matter from a knowledgeable person.

The largest configurations are designed for two people. However, they take up a lot of space in the room. Therefore, before starting work, it is necessary to measure the space allocated for the bed in the room. And also take into account such parameters as space for a bedside table and only space for free movement.

The main difficulty lies in the preparation of components and their processing.

Another important factor is the choice of mattress. When performing work based on established standards, it is necessary to take into account that this must be done to order.

The main thing is a little patience and self-confidence.

Conclusion

Now we know how to choose the right bed for the bedroom.

- First, let’s make sure of the strength of its frame and the reliability of the fasteners.

- Only environmentally friendly materials are acceptable, for this we will familiarize ourselves with the certificate.

- A guarantee of assembly and subsequent operation is required.

When choosing a bed, let's lie down on it. If at the same time it does not creak or crack, and we feel free, then the frame and foundation are good. If it’s easy for us to turn over, the mattress is suitable for us (see also the article “Pelmets for the bedroom: models and useful tips for choosing them”).

The video in this article will help us in our selection of a comfortable bed.

Types of structures

Egypt can rightfully be considered the birthplace of metal beds. Only the rich could afford them. They were a sign of wealth and luxury. In the Soviet Union, iron beds were made according to a template and were not very elegant. Today the situation has changed dramatically. Metal objects have appeared on the furniture market, differing in their manufacturing method. These include the following types.

- Forged structures - have a solid base made of metal pipes. Pipes with sections of different diameters, which allows you to recreate a variety of scenes in the design. Weight does not exceed 50 kg. There are two types of forging: cold and hot. In the first option, all manipulations with metal are carried out using a special apparatus. The process is more like stamping. In the second case, the master works with his own hands. The metal heats up to +600 C. Using forging, you can recreate an object in any interior style: classic, modern, rococo, baroque, ethno, high-tech.

- Welded structures differ from forged ones in that the finished parts of the future product are connected to each other by welding. Products made in this way are less original: classic or modern.

Before starting work, you need to decide on the future dimensions.

Any bed consists of a frame, frame, back, legs and fastenings. The main elements that serve as the basis for any bed are the structure and frame. The frame serves as a support. It consists of a back and side panels. Frame: The part where the mattress sits. Particular attention should be paid to the headboard during manufacturing. It plays a decorative role and completely sets the tone for the entire product. Forged elements are used as decoration. They can be bought ready-made.

In the case of modernizing an apartment or room, you can move away from the usual stereotypes and find a new place for it.

Styles

Thanks to the abundance of different options, a metal bed can fit into almost any style of space. You just have to choose the right backrest design and the right accessories.

You can fit a metal bed into a retro style, Provence or any other:

- Modern styles of minimalism, hi-tech, loft accept the simplest models with straight crossbars on the back, which form something like a lattice. Such a bed can be made in white, black or steel colors, and in addition it is acceptable to use bright accents in the form of pillows or bedspreads.

- White metal beds with patterned headboards will help add romance to the room; a light canopy in light colors will be an excellent addition here.

- Exquisite ornamentation, rich decor, and the colors of noble metals will be an excellent option for a bedroom in the Art Nouveau or Baroque style.

Preparation for the process

Before you start making an iron bed with your own hands, you need to carefully familiarize yourself with the available models and designs. Assess the complexity of production and its capabilities. Most of the options are quite simple to implement and can be implemented even by a beginner.

There are standard types of beds: single, double, one-and-a-half.

The next step is to make a plan. Describe all steps, materials and tools. This will save money and time.

Determine the size and model according to your wishes.

Metal objects have appeared on the furniture market, differing in their manufacturing method.

In order to make a metal bed with your own hands, you need to go through a number of preparatory stages intended directly for production.

- Draw a drawing of the product.

- Purchase of materials.

- Before making a bed, measure the dimensions of the mattress to determine which one is best to buy. This will make it possible to compare it with the product during production.

Forged structures - have a solid base made of metal pipes.

Tips for choosing

When choosing a beautiful and comfortable single bed, you must rely on the following criteria:

Price. Solid wood products are high quality and environmentally friendly. However, such options are quite expensive

If you don’t want to overpay for a natural wooden bed, you should pay attention to economy class models - made of iron, MDF and chipboard.

Size. You need to first measure the bedroom so that you can choose a bed of suitable dimensions

For a small apartment, a compact model is suitable, not burdened with unnecessary decorative details (sides, shelves, cabinets, etc.).

Design. The appearance of the bed should be in harmony with the interior of the bedroom and not stand out from the overall ensemble. Simple and beautiful furniture in a positive color is ideal for a children's bedroom. There is no need to burden such a space with a luxurious bed in an elaborate design.

Manufacturer. High-quality and durable single beds are produced not only by domestic ones, but also by Belarusian, Italian factories, and manufacturers from Malaysia. The most expensive are Malaysian and Italian designer models. These imported products are made from natural wood and have stunning designs.

Take into account a variety of nuances. Only in this case will you be completely satisfied with the purchase.

Tools for work

To make a welded iron bed with your own hands, of course, you will need a welding machine. Plus other tools:

- angle grinder (grinder);

- drill with a set of metal drills;

- roulette;

- square;

- square file;

- metal brush;

- sandpaper;

- brushes;

- primer for metal surfaces;

- painting.

Welded structures differ from forged ones in that the finished parts of the future product are connected to each other by welding.

For counterfeit goods, in addition to the main list, you will need to add the presence of blacksmithing equipment. Depending on the type of forge, the set will also be different. So, the cold forging kit includes:

- snail – allows you to create spiral patterns;

- bending machine - designed for bending metal rods at various angles;

- lantern - for creating parts with the same name “lantern”;

- tornado – twists the rods along the longitudinal axis;

- volumetric – allows you to make three-dimensional patterns;

- wave - equipment for creating wavy patterns.

Any bed consists of a frame, frame, back, legs and fastenings.

For hot forging you will need a forge, anvil, shperax, handbrake, mallet, tongs, and hammers.

You may not need all the equipment. The choice will depend on the end goal.

Step-by-step technology for creating an iron bed

Creating an iron bed includes preparatory work, installation and processing of the finished product.

The process starts from the back. For this purpose, blanks are prepared from profile pipes according to the drawing. They are laid on a flat surface, fastened and fixed by welding. The degree of angles must be controlled to achieve a uniform design.

Next, steps and plugs are installed on the back side of the open parts of the pipes.

At the next stage you will need to use a grinder and a channel. To support the frame, supports are made: 2 central and 4 side, with a slope of 5 degrees. Fasteners connect the back to the frame with a continuous weld. The optimal distance from the ground is 0.35 m.

To give the bed sophistication, all seams and protruding elements are cut off with a grinder, processed with a special brush and grinder to the metal base.

- Preparation of material for frames.

Steel channels are cut into blanks. The size is determined based on: the length of the frame plus 5-6 cm. The channels are connected by corners. For better quality of joining, protruding areas are cut off at the corner horizontal shelf. The joints, as in the previous version, are welded with a continuous seam.

When performing work based on established standards, it is necessary to take into account that this must be done to order.

- Installation of frames.

The backrests are placed in a strictly vertical position, the frames are adjusted, and grooves are marked on the lower channel. Holes are made with a drill with a diameter of no more than 9 mm. The drilled holes are adjusted to the shape of the tenon using a file.

Another important factor is the choice of mattress.

Assembly of the main part is complete. The next step is to weld the grid under the mattress. It is welded to the finished frame.

Next, steps and plugs are installed on the back side of the open parts of the pipes. They are usually covered with steel circles.

Therefore, before starting work, it is necessary to measure the space allocated for the bed in the room.

To give the bed sophistication, all seams and protruding elements are cut off with a grinder, processed with a special brush and grinder to the metal base.

Finishing is carried out on a well-prepared surface: a primer is applied, then it is varnished and painted.

Advantages of beds made of metal

Despite the complex process, metal beds have a number of advantages. Here is a list of some of them:

- respect for the environment;

- wear resistance;

- hygiene;

- reliability – resistance to mechanical damage and weight loads;

- variety of design and style;

- light weight, which is convenient when rearranging furniture;

- not exposed to fire.

The largest configurations are designed for two people.

The metal bed has an attractive appearance and will fit perfectly into any interior. And if you have certain skills and a set of tools, the process will not be difficult. Also, this type of activity is an excellent option for developing creative abilities and, as a result, obtaining an individual piece of furniture. An iron bed made by yourself will serve for a long time and reliably.

You also need to consider the width.

Bed base and headboard

The base of the bed is made of wooden or metal slats, or reinforced metal mesh. The first option is considered more comfortable and modern. In addition, double beds generally use only slats. In addition, the more slats, the better the bed will support a person’s weight and distribute the load. The distance between the lamellas should not exceed the width of one lamella.

A bed with a base made of metal mesh will be cheaper and will last at least 20 years, but the reinforced mesh tends to break through over time, so after a while it will no longer be very comfortable to sleep in such a bed; it will need to be repaired.

Unlike a footboard, almost all metal beds have a headboard. Its main function is to serve as a support for pillows. The secondary task is to decorate the bed itself. Even if the main part of the bed is welded, many manufacturers make the headboard from forged elements. The more complex the lace pattern, the higher the price. Often forged elements are additionally decorated with gilding. But forged beauty will not always be appropriate. For modern interiors, the most simple and laconic headboard in the form of several horizontal slats or a lattice is suitable.

Varieties

All metal double beds are divided into two types: forged and stamped. They differ in the manufacturing method, materials used, and cost. What are the features and advantages of each option:

- Stamped products come off the factory assembly line, that is, they are mass-produced products. For their manufacture, iron is mainly used, and sometimes alloys of brass or copper are used. The structure is assembled from hollow tubes and a profile with a thickness of 1.5 mm. The main advantage of finished products is their lightness, while the weight they can withstand reaches 200 kilograms.

- Forged beds are made by hand. This is a piece product that is made according to individual or ready-made sketches, often made to order. This method involves high heat treatment of the metal, which adds additional strength to it. Forged products can also easily withstand weights of over 200 kilograms. Each model is unique in its own way, revealing the individual handwriting of the master.

The cost of the product is directly affected by the manufacturing method; it is clear that handmade work is always valued more highly. In addition, the metal used to make the bed is important.

Stamped

Forged