Installation of cladding, facade or decorative panels without drilling holes, non-destructive fastening of lining - a large number of such tasks can arise for a finisher or repairman. There are many methods for performing such work, but most of them require experience and high qualifications. At the same time, it is impossible to guarantee a positive result - “surprises” may arise at any moment in the form of broken pieces, broken edges and other troubles.

However, there is a simple and very reliable way to fasten such materials using clamps. They are almost completely free of problems and allow even completely untrained people to carry out high-quality installation. Let's take a closer look at these elements.

Pros and cons of using MDF panels in the interior

MDF panels are made from fibreboard. This material has distinctive positive aspects:

- It attaches easily to the wall and has multiple fixing methods;

- Acts as a sound insulator;

- MDF panels hide wires, pipes and other communications;

- They are easy to care for;

- Thanks to them, you can create an attractive design for your kitchen, living room, bedroom, loggia, balcony or hallway.

MDF panels are easy to attach to the wall and have many ways of fixing.

Like all finishing materials, MDF panels also have their disadvantages:

- They tend to burn and are subject to instantaneous combustion;

- They do not like moisture and become deformed in high humidity;

- To hang objects on these panels, you will need to use special fasteners (Fischer anchor).

MDF panels do not like moisture and become deformed in high humidity.

Clasps for lining - covering without damaging the material

Lining is a natural building material that is traditionally used for external and internal cladding of houses, buildings, balconies, baths, and saunas. It has earned popularity among consumers due to its excellent technical characteristics, reliability and attractive appearance.

Modern decorative cladding materials are made from both artificial PVC and MDF, and natural wood (pine, linden, aspen and others). Installation of wood trim is usually done using finishing nails or using a furniture stapler.

Although this option is the simplest, it does not always have a favorable effect on the appearance of the clapboard board and completely eliminates the possibility of dismantling the coating without damaging the material. More practical and modern is the installation of lining on clamps.

Preparing the premises and marking

Preparing the room is done in different ways and depends on the type of fastening. When attaching MDF panels to the wall without using a frame, you will need the following preparation:

- Clean the surface from old finishing material;

- Treat against dampness;

- Dry the walls;

- Check them for changes. If they are large, it is necessary to plaster and prime the walls.

You will also need to make markings. This is done with a level and a pencil, as well as a homemade or purchased weight.

Markings are done with a level and a pencil, as well as with a homemade or purchased weight.

What it is

A kleimer, or mounting clip, is a fastening element designed for the hidden installation of sheathing or cladding of various types.

The name “kleimer” comes from the German word “klammer”, meaning “bracket, clamp, clamp.” Based on the spelling of the word, another variant of the name is often found - “clammer”. This does not change the meaning; as a rule, there are no fundamental disputes about terminology.

Externally, it looks like a stamped plate, in the center of which there is a mounting element in the form of a bracket. The plastic has holes for screws with which the clamp is attached to the supporting surface (wall, sheathing, other planes).

The protruding bracket engages with the end part of the attached element (usually from the side of the longitudinal groove) and securely holds the skin. The next element is inserted into the groove and, in turn, secured with a clamp - etc. No fasteners are visible from the outside, the sheathing fabric looks very neat, without irregularities or protrusions.

There are other types of clamps designed for mounting certain materials. They have different shapes and number of staples, but the general principle is always the same.

Clamps are made of spring steel or (more often) of galvanized sheet steel with a thickness of 0.5-0.8 mm. Of all the hardware, these parts are the least known to users, although everyone has encountered them at least once in their lives. For example, attaching mirrors to support plates made of thick plywood or woodworking panels are also clamps specialized specifically for this task.

Most users know this type of fastening, but have no idea what it is called.

Working with such a mount is very simple and convenient. You just need to select suitable screws or nails that match the diameter of the holes in the plates. The easiest way is to buy sets (usually 100 pieces), where the hardware is equipped with suitable nails or screws.

Methods for attaching MDF panels to the wall

Professional craftsmen have several popular methods for mounting MDF panels. Each method will be discussed step by step.

Using lathing

The fastening of the sheathing will depend on how the panels are mounted - horizontally or vertically. It can be directly made of wood or metal.

If a master wants to make a lathing from wood, he is recommended to use bars 20 by 40 millimeters. They are first treated with a special antiseptic liquid. The frame is mounted using dowel nails or self-tapping screws.

If the sheathing is metal, it is sewn together strictly with self-tapping screws.

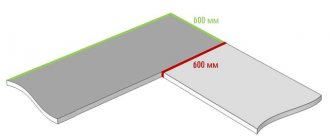

The length of the fastener itself can be selected based on the thickness of the sheathing bars and the plaster layer. According to the rules, the fasteners should be slightly recessed into the wall by 30 millimeters. The sheathing pitch can be equal to 60 centimeters.

Vertical pieces of sheathing are attached end-to-end to the corner and 90 degrees relative to each other. After each row, you need to check the installation for evenness using a water level.

The top/bottom slats, located horizontally, were attached with a small indentation from the ceiling and floor. After all, the baseboards will then be attached to these slats.

Next, you need to trim the doors and windows, or rather their openings. The remaining horizontal pieces are mounted at a distance of 50 centimeters from each other. The metal frame is attached in the same way as wood sheathing.

If the sheathing is metal, it is sewn together strictly with self-tapping screws.

With glue

To attach fiberboards to the wall using glue, you will need:

- Prime the wall and mark the surface for the 1st slab.

- First spread the glue on the boards themselves in the form of a thin dotted line and wait a little. In this case, the waiting time is selected based on the instructions on the glue.

- Next, you can apply the material to the wall, pressing it tightly.

- Installation with glue is used when the base is concrete or brickwork.

Installation with glue is used when the base is concrete or brickwork.

Without sheathing

MDF panels without sheathing are usually attached to the surface using self-tapping screws. This method is used if the base is a wooden surface.

You should not take risks and screw the slabs onto self-tapping screws if the surface is not wooden. After all, self-tapping screws tend to weaken over time. As a result, the MDF becomes loose and deformed.

MDF panels without sheathing are usually attached to the surface using self-tapping screws.

For liquid nails

Attaching MDF boards through liquid nails occurs in exactly the same way as when attaching with glue. The only thing you need to take into account is that there is no need to wait for some time to fix the glue to the slabs. Indeed, if this rule is not followed, the adhesion to the surface will decrease. If the glue is not wiped off in time, the appearance of MDF will easily deteriorate.

Clamps

Clamps are used when covering walls using a metal frame. The clamps are attached to the sheathing with self-tapping screws. Then do the following:

- Measure and cut the first slab according to the markings.

- If necessary, holes are made in it for communications.

- The panel is placed in a corner and screwed on one side with self-tapping screws. On the other hand, the plate is secured with clips.

- All subsequent MDF panels are secured using clamps and locks.

- Next, attach the baseboard to the ceiling and floor with glue.

- At the end, fix the last corner. It covers the screws located in the corner. They are fixed with an adhesive base.

- After this, the entire wooden surface will need to be wiped with a wet cloth.

Clamps are used when covering walls using a metal frame.

Other possible options

It is also possible to mount fiberboards on polyurethane foam. This type of fastening is used in rooms most exposed to moisture.

How to choose

Selecting suitable clamps is not a difficult task if you have some experience in handling such products. However, for an unprepared person, making the right choice of hardware is not easy. There may be a lot of options on sale that look quite suitable for the existing purposes.

Therefore, it is necessary to understand the selection criteria that will guide you:

clip number . This is the main parameter, which is often sufficient to resolve the issue (the passport of some materials directly indicates the number of the clamper);

quality of steel, presence of protective coating and its condition . As a rule, galvanized hardware is sold. It is necessary to inspect several pieces and check the integrity of the galvanization, the absence of peeling or rusty areas;

for some materials (vinyl panels, regular lining, MDF or OSB up to 14 mm thick), the usual type of hardware is suitable . Thicker sheathing will require reinforced products suitable for laying floor laths, thick sheet materials or sheathing elements;

it is necessary to measure the dimensions of several elements and make sure that they correspond to each other . This is an important point, since during storage the remains of different hardware that are similar to each other are often dumped into one box. Externally they are identical, and only checking the sizes will make it possible to verify the differences.

When purchasing fasteners, it is necessary to have accurate data on the dimensions of the sheathing or other materials to be attached. The best option is to have a sample with you, to which you can try on different types of hardware to determine the most successful option.

It must be remembered that all types of cladding are produced by different manufacturers and may have deviations from standard sizes. Therefore, the opportunity to try clamps on a sample will help eliminate mistakes and buy elements of the correct size.

Methods for insulating walls to preserve the appearance of MDF panels

If the master decides to insulate the walls in order to preserve the appearance of the wooden slabs, he can use the following methods:

- After installing the frame, fill the empty space with foam boards or other selected insulation;

- Glue penofol with a top layer of foil up to 3 millimeters thick before attaching the sheathing.

The insulation can also be mineral wool, penoizol, penoplex, foamed or extruded polystyrene foam, polyurethane foam.

After installing the frame, fill the empty space with foam boards or other selected insulation.

Necessary tools for work

To carry out installation work you will need:

- hydraulic or laser level or plumb line;

- metal square;

- electric screwdriver or drill;

- a set of nozzles for tightening screws;

- hammers with metal and rubber heads;

- metal scissors (in case of assembling a frame from a profile);

- construction gun for applying glue;

- wood hacksaw or electric jigsaw with a set of files;

- tape measure, metal ruler and several sharpened pencils.

Tips and tricks for attaching MDF panels to the wall

Below are recommendations that will help novice craftsmen correctly install wood panels:

- Before installation, it is necessary to treat the walls with an antifungal solution and prime them.

- If the slabs are very difficult to cut by hand, you can use an electric saw or jigsaw.

- In order for wooden slabs to directly retain their external qualities for a long time, it is better to insulate the walls before installation.

- Drilling the required hole for communications in the slab is easy. For this, a core drill is used.

- If finishing is done horizontally, you need to wait until the glue on the very first panel dries well. After all, the first panel is the support for all subsequent ones.

If finishing is done horizontally, you need to wait until the glue on the very first panel dries well.

Attaching MDF panels to walls is not an easy process. It requires certain skills, time and strict adherence to instructions. But if these conditions are met, even a beginner will be able to complete the finish efficiently.

How to calculate the required quantity

Before purchasing mounting clips, you need to determine their quantity so that you do not have to stop work and go to the store for the missing elements.

The necessary calculation is based on determining the length of the sheathing elements and the sheathing pitch.

Procedure:

- the length of the panels (beams or other sheathing elements) is measured;

- the pitch of the sheathing planks is determined (it is necessary to take into account the distance between the axes of the planks, and not between their edges);

- the length of the panels is divided by the sheathing pitch (rounded to whole numbers) and one is added to the resulting value.

After this, all that remains is to multiply the resulting value by the number of panels. This is how the number of clamps for the sheathing installed on the subsystem (sheathing) is calculated.

However, continuous flooring is often sheathed. In this case, the procedure is simpler - the length of the panel is divided into equal parts (you need to focus on 50-60 cm). This gives the number of clips on one panel. After this, you need to multiply the resulting number by the number of panels, which will give the total number of hardware.

It is necessary to have a small supply of clamps - in some areas, plane transitions or places of longitudinal connection, an increased number of fasteners will be required. Therefore, the total quantity is increased by 10% to ensure the required supply.

Peculiarities

Clamps are a special fastening structure of high strength, it is used for mounting various wooden panels. They are installed under the material. Such frame parts are secured using self-tapping screws and nails.

Externally, clasps are similar to ordinary metal staples or clamps. They are quite plastic; they are attached to the surface in such a way that their tongue protrudes slightly outward, after which they are slightly bent upward.

Such elements are considered a more profitable and reliable option compared to nails and screws. After all, the latter often begin to rust and spoil the overall appearance of the entire structure. Claypers are usually made of high-quality stainless steel, so over time they will not rust or lose their appearance. Sometimes these elements are made from aluminum.

Visually, such fasteners can also be divided into two separate categories: flat metal plate and “hook”. The first variety is created with several small holes. It is thanks to them that attachment to the surface occurs. The second option is also called a “tongue”; it looks like a small holder that is tightly inserted into the lower part of the groove of the lining.

All clamps must be marked with numbers (from 1 to 8). These values indicate the hook height of such structures in millimeters. In addition, they can reflect the strength of the product itself. The size of any clamp is always commensurate with the thickness of the groove of the finishing material.

Claypers make it possible to avoid various defects that occur when fastening MDF panels; they do not violate the integrity of the surface.

In addition, this frame makes it possible to ensure special reliability of the future coating. Wooden sheets will not deform during operation; they will allow the wood to “breathe”.

Cleimers are quite easy to install on coatings. They significantly speed up the process of installing wood, and they are relatively inexpensive; anyone can purchase them. For one square meter of room you will need about 20 clamps.

They are often fixed in bathhouses; such elements are resistant to low temperatures and high humidity (they are coated with special compounds that protect them from rust and other influences).

These fasteners are best used only for lightweight wooden finishing sheets. They will not be able to withstand too much load. The clamps are suitable for the following materials:

- lining;

- eurolining;

- MDF panels;

- chipboard panels;

- block house;

- baseboards.

Such fasteners make it possible to make the frame invisible after installing the MDF panels.

Parts can be mounted in such a way that they are not visible at all, but this can only be achieved if their dimensions have been selected correctly.

Dimensions

Fasteners are available in several types, which depend on the thickness of the groove into which the bracket is to be attached. The sizes of clamps for lining are as follows:

- No. 1 – used for fastening PVC lining and panels 5 mm thick;

- No. 2 – used for panels 8 mm thick made of PVC or MDF;

- No. 3 – purchased for installation of eurolining and wall panels made of chipboard;

- No. 4 – mainly used for fastening eurolining;

- No. 5 – used for installation of clapboard boards;

- No. 6 – recommended for indoor block houses.

Installation of sheathing

To use clapboard clamps during installation, it is necessary to install the sheathing. What is it for:

Lathing helps you begin installing panels without having to perfectly align the walls. This is especially true for concrete or brick foundations, which simply are not 100% level. We level the wall as best we can and proceed to the next stage.

It is easier to attach the lining to wooden beams than to a base made of other materials.

The space that remains between the wall and the decorative panel promotes good ventilation, which prevents the formation of dampness, mold and mildew.

During installation of the sheathing, in order to increase its service life, it is important to pay attention to a number of the following points:

It is important to use a building level during installation. Otherwise, curvature of the decorative lamellas may appear, which will be noticeable and spoil the aesthetic properties of the finish;

The distance between the bars should be at least 60 cm, this will help prevent deformation or sagging of the lining strips.

Useful tips

Compliance with these recommendations will help extend the service life of the lining and preserve its appearance of the panels in their original condition for a long time:

It is recommended to buy clamps for lining in trusted construction stores. This eliminates the possibility of getting a fake instead of high-quality material, which will lead to rapid failure of the clamps.

It is also not recommended to use liquid sealant to form joints; this can affect the condition of the fasteners and cause corrosion.

It is important to control the room temperature during installation work. The difference with the outside temperature should not be more than 10 degrees. When working with wooden materials, the temperature outside should be above zero.

To work with plastic lining, the air temperature must be at least +10 degrees.

To protect both the lining panels themselves and the fastening elements, after completion of the work it is necessary to cover the slats with varnish, wax or stain.

Installation of panels in a horizontal manner begins from the top corner. This will help maintain the aesthetics of the last plank, and if, when installing the outer lamella, it needs to be shortened, this flaw can be covered with a plinth.

Holes for sockets and switches are made before covering the paneling with varnish.

To decorate a room with wooden paneling, the wall itself must also be treated with a primer before starting work.

The purchased material (lining) must lie in the room for at least a day before installation. This will help avoid problems after the material expands or contracts as a result of changes in temperature and humidity.

The lining panels should not be adjacent to the wall, floor or ceiling. This will have a bad effect on ventilation. This will lead to the formation of fungus, mold and corrosion of fasteners.

In order to hide the space between the first plank of the lining and the floor, it is necessary to use a plinth specially designed for this.

When purchasing clamps, it is important to pay attention to the material from which they are made. This is especially true when purchasing fasteners for street cladding.

The metal must not be susceptible to corrosion so that this does not affect the condition of the wooden panels.

Description of steel clips

Those who are engaged in construction quite often have to attach lining to the walls or ceiling of premises.

This is the most suitable material for covering a loggia, balcony, bathhouse or sauna, both inside and outside.

It is easy to assemble a lining that is attractive in appearance, but this must be done using special fastening elements.

Self-tapping screws and nails should be discarded, as they can damage the material, leaving chips and cracks on it.

The best fastening element for lining is clamps. They can be called steel clips, used in the installation of various building materials, consisting of many individual fragments.

The clamps are made of galvanized metal that is not subject to rust even at high air humidity.

Most often, the lining is secured using simple steel clips coated with varnish, so they cost less.

By their design, the clamps resemble rectangular plates.

Initially, these fastening elements seem complex, but in fact they are very simple - they have curved tabs that fix the front surfaces, and special grooves that allow you to attach the lining.

Clamps come in regular and starter types. Steel clips of the first type are used when it is necessary to join two panels, since they have 4 tongues.

Fasteners of the second type are used if you need to fix materials from the sides, bottom or top of the facade, since they are produced with only 2 tongues.

Fastening the lining with clamps is preferable to fixing it with nails or other fasteners, because it does not harm the finishing material in any way.

The production of steel clips is aimed at making the structure stable and reliable.

In addition, clamps have many more advantages:

- are elementary to assemble;

- almost invisible on walls or ceilings;

- are also used for fixing plastic panels or block houses;

- do not require additional components;

- almost do not lead to the appearance of defects in the design (if they arise, they are a consequence of installation errors).

In order for all actions for covering a room with clapboard to be correct, it is necessary to purchase clamps that have certain dimensions.

This product parameter is reflected in special numbering. More specifically, when choosing clasps, their distance from the bracket to the base is of particular importance. It should be 2 mm.

It is necessary to take into account other sizes of steel clips, including their thickness. This parameter can be from 0.5 to 0.55 mm. It is also important to pay attention to the height of the tongue.

For example, installation of eurolining requires that the clamps have a tongue height of 4 mm. To fasten thin boards with a rounded front surface, it is best to use steel clips with a tongue whose height is 6 mm.

In addition, you need to know the dimensions of the walls and ceiling in order to equip yourself with the required number of fasteners.

Application

Hardware is used in matters of construction and finishing, where it is impossible or undesirable to use nails, due to the fact that the appearance can be spoiled. Before use, you need to assemble a wooden or metal structure in the form of guides, which are installed level in the same plane.

The number of guides for fastening must be at least 3 pieces, where the material will be fixed in the center and along the edges. It is recommended to use at least 5 guides per length of three meters.

Claymer for lining

Place the hardware evenly. When using self-tapping screws and screwing them into wood, it is recommended to drill to prevent cracking of the guide.

The scope of application is such that gluers are used by private individuals in matters of finishing, as well as by professional builders. For example, it is used when finishing a bathhouse with clapboards made from any type of wood. It is used for installing MDF panels in hallways and kitchens, for lining ceilings, and for arranging floors in gazebos and loggias by laying decking boards.

Galvanized clamps No. 2 (with nails), 100 pcs. in Moscow

Galvanized clamps No. 2 (with nails), 100 pcs. and other products in this category are available in the catalog of the Leroy Merlin online store in Moscow at low prices. Read the detailed characteristics and description, as well as reviews of this product, to make the right choice and order the product online.

Buy products such as galvanized clamps No. 2 (with nails), 100 pcs., in the Leroy Merlin online store, having first checked their availability. You can receive the goods in Moscow in a way convenient for you; to do this, read the information about delivery and pickup.

By subscribing to the newsletter, I consent to the processing of personal data and to receive advertising messages and news about products and services

Leroy Merlin stores leroymerlin.com

Preparing the premises and marking

During the preparation process, the wall must be dry. Damp surfaces cannot be treated in any way.

Expert opinion

Strebizh Viktor Fedorovich, leading construction foreman

The panels are marked using a construction angle and a tape measure, drawing the corresponding lines, along which a cut is made using an electric jigsaw, a manual vertical circular saw or a regular hacksaw. If you want to clarify something, please contact me!