Date: October 17, 2022 12:45

Today there is no shortage of furniture in stores. Anyone can choose the right model in various designs and colors. However, the quality often leaves much to be desired: the service life is short, use is uncomfortable, wooden structures dry out, and fabric upholstery fades. That is why businessmen who want to gain worthy authority in the furniture market have something to develop, and the process of producing high-quality furniture is promising and in demand. In addition, more and more people are inclined to make custom-made furniture. It is original, convenient, and shapes the face of every home.

Features of the business: target audience, assortment, raw materials and production methods

Each niche has its own characteristics. Knowing them, you can avoid possible risks. And first you need to understand who the target audience is.

Who buys cabinet furniture

There are four categories of target audience on the market.

- Young families with children under 5 years old: trying to quickly and inexpensively equip a new apartment.

- Families with school-aged children (6 to 15 years): value practicality and affordability.

- Retired: Looking for something inexpensive and simple.

- New companies and organizations: are constantly in need of office furniture.

It is these four types of target audience that future business should be targeted at.

What do people buy most often?

Having understood who your target audience is, you need to find out what they prefer. Practice shows that emphasis should be placed on furniture:

- kitchen

- office

- dacha

- nursery

- for bedrooms

By offering such a range, it is possible to cover the main part of the market. Of course, large investments will be needed at the beginning. But this will lead to quick payback and high profits in the future, subject to a competent marketing strategy and high quality products.

What can cabinet furniture be made from?

The choice of raw materials from which cabinet furniture is made is not as large as it might seem. There are four main materials that can be used in your work.

| Material | Description |

| Chipboard (chipboard) | The boards are produced by pressing wood chips and gluing them together. Wood shavings are wood processing waste. This material has high strength, rigidity and a uniform structure. Easily processed. Has low cost. |

| laminated chipboard (laminated particleboard) | Laminated chipboard is produced in the same way as regular chipboard, but the boards are lined with paper impregnated with a special resin. This material has even greater strength and wear resistance. |

| MDF (fine fraction) | This material is obtained by pressing sawdust. It is environmentally friendly and easy to process. During operation it does not dry out, does not crack, retains heat and has good sound insulation. One of the most popular materials for the production of cabinet furniture. |

| Array (natural wood) | Natural wood: birch, walnut, oak, pine, etc. Material for luxury products. The most expensive type of raw material, characterized by durability and environmental friendliness. |

“The more expensive the material, the higher the price of the final product. A product made from chipboard and laminated chipboard will cost less than one made from MDF and, even more so, from solid wood. Therefore, the assortment must be determined taking into account the solvency of the target audience.”

How to produce: types of technological processes

There are three production methods.

- Full cycle - from the production of materials to the receipt of finished products. This method includes all technological processes necessary to create furniture. This also includes delivery and assembly. This option is suitable for large enterprises or medium-sized companies. A small business, such as a sole proprietor, should consider the following two options.

- The middle cycle involves cutting finished sheets of chipboard, laminated chipboard or MDF and subsequent assembly. A less expensive method that requires less time and equipment than the full cycle.

- Short cycle is the most economical of all technological processes. The furniture is assembled from materials already pre-cut by the supplier. All work consists of installing fittings and subsequent assembly. This cycle is suitable for a small company or individual entrepreneur.

If you decide to produce upholstered furniture...

Unlike cabinet furniture, upholstered furniture is often made by hand, using additional equipment, including sewing machines, upholstery devices, and fastening accessories. In addition, it is necessary to provide for the need for strong fastening of spring mechanisms, fasteners, fillers, etc. The quality of upholstered furniture largely depends on the class of upholstery materials, methods of fastening fabrics, mechanisms that ensure the strength of seams and joints of parts.

The production of upholstered furniture partially repeats the processes occurring in the manufacture of cabinet samples. However, only partially. Its manufacturing technologies have many specific aspects, knowledge of which determines the quality and service life of the produced models.

In addition to the correct manufacture of products, the authority of the furniture manufacturing enterprise, incl. small and medium scale, depends on the legal legitimacy of its activities.

GOSTs you need to know

Before registering with the Federal Tax Service and starting a business, you need to study the rules governing the production of cabinet furniture. These include GOSTs:

- 16371-93 - general technical conditions.

- 19882-91 - Test methods for deformation, strength and stability.

- 28105-89 - test methods for drawers.

- 1-85 - dimensions of storage compartments.

- 28136-89 - test methods for wall cabinets, shelves, etc.

- 4-86 - dimensions of office furniture cabinet compartments.

“You can get acquainted with the GOSTs of the Russian Federation on the website of the Federal Agency for Technical Regulation and Metrology “Rosstandart” gost.ru.”

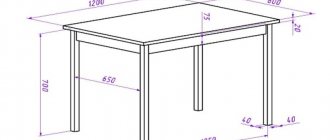

Cutting blanks

Modern furniture, as a rule, is made from wood panels, so an important stage in its production is cutting - the process of cutting out parts from a solid chipboard board. It is best to do this using a cutting machine, since it will cut the slab with maximum accuracy. The cutting is carried out in accordance with the drawing, the chipboard sheet is pre-marked to the dimensions of the parts. Curvilinear sections are cut with a jigsaw.

Registration: management forms, OKVED and documents

For the production of cabinet furniture, you can register an LLC or individual entrepreneur. The form of business management depends on the scale of the enterprise. If mass production is planned, then LLC will be optimal. If the products will be made to order and in small batches, then individual entrepreneur is better.

To register with the Federal Tax Service you will need to provide:

- Charter and constituent documents (for LLC).

- Receipt for payment of state duty: 800 rubles. for individual entrepreneurs, 4000 for LLC.

- Bank details: bank accounts.

- Application form P21001 for opening an individual entrepreneur or P11001 for an LLC.

When registering, you also need to indicate OKVED codes.

For production.

- 36.12 - furniture for offices and retail establishments.

- 36.12 - for the manufacture of kitchen furniture.

- 36.14 - production of other furniture.

For sale.

- 52.44.1 - retail sales.

- 51.47.11 - wholesale sales.

- 52.61.2 - retail sale through teleshopping, radio, online stores or by telephone.

In addition to the Federal Tax Service, you must register with the pension fund. Do not forget about the mandatory authorized capital for an LLC - from 10,000 rubles.

“If registering a business seems like a complicated and time-consuming process, then it can be delegated to a law firm. The lawyers will carry out all the necessary procedures themselves and hand over the completed documents to you.”

Story

In pre-revolutionary Russia, furniture production was semi-handicraft in nature. Large factories were concentrated in St. Petersburg, Riga, Kyiv, and Moscow.

The production of furniture on an industrial scale began in the 1950s. Most of the products satisfied only the needs of the domestic market.

With the transition to an open market, competition has increased. Enterprises had to modernize, adapting to new conditions. In most cases this was done successfully.

Equipment and tools

To competently organize a small workshop for the production of cabinet furniture, you need to purchase all the necessary tools and equipment. This is what will constitute the main expense item.

The following equipment will be required:

- Format cutting - 300,000 ₽.

- Edge banding - 700,000 ₽.

- Drilling and filler - 50,000 ₽.

- Drying - 300,000 ₽.

- For working with glass: sandblasting, cutting, drilling - 26,000 ₽.

Tools you will need:

- Grinder - 5,000 ₽.

- Screwdriver - 5,000 ₽.

- Perforator - 6,000 ₽.

- Milling cutters - 3,000 ₽.

- Knives - 2,000 ₽.

- Drills - 20,000 ₽.

Total: 1,417,000 ₽.

As a result, in order to purchase the necessary equipment and tools, you need to have 1,500,000 rubles. But this is not the entire cost item.

“Please note that the factory will need a special computer program to create the furniture design. Such software can be easily found on the Internet: paid and free versions.”

Premises for office, workshop and warehouse

The optimal room area is 500 m2.

An office and a showroom will be located on 50 m2. On 100 m2 there will be a warehouse for storing raw materials and finished products. The remaining 350 m2 will be used for the workshop.

The cost of renting such a premises will be about 200,000 rubles per month. But the final price will directly depend on the region, location and area.

The following requirements apply to the premises of furniture factories.

- Availability of water supply, sewerage, air conditioning systems.

- Connection to a three-phase electrical network 380 W.

- All rooms are located on the ground floor.

- Availability of loading ramps and convenient access roads.

- Normal humidity, corresponding to the rules for storing wood and finished products.

- The temperature in the warehouse and workshop premises must be constantly maintained within 18-20 °C.

- It is mandatory to have fire extinguishers, working fire extinguishing and alarm systems.

Before the opening of the enterprise, you need to contact the State Fire Inspectorate, which will inspect the premises and issue the appropriate certificate. It is also worth remembering about the SES and Rospotrebnadzor - these authorities must also conduct inspections and issue work permits.

Where to start?

The organization of a furniture business should rely, first of all, on the professionalism of the craftsmen, their experience, initiative, and desire to improve the methods used. It is recommended to move forward in development gradually.

So, initially it is useful to work “to order”. In this case, there is no need to have large warehouses, and you do not need a lot of raw materials and consumables. However, in this case, it is important to have an understanding of customers and their needs in advance.

The business plan for a small furniture production at the next stage should contain advertising activities. Experts recommend using catalogs, booklets, and business cards outlining the advantages of a given manufacturer’s products. Online advertising is effective, especially on social networking sites.

It pays to maintain a retail outlet where your own products are sold, as well as transport that will deliver raw materials and finished goods to the store.

The opening of a furniture business is preceded by targeted methodological work. You need to carefully study publications that contain everything about the furniture business, get acquainted with the experiences and mistakes of other entrepreneurs, analyze offers on the market and the requests of potential buyers. It is useful to get a clear picture of competing companies operating in the selected area, the availability of suppliers of raw materials, and the possibility of purchasing modern equipment.

In a competitive world, it is important that the work is done by professionals. This will allow the company to gain its own authority. The business plan for the production of kitchen furniture also provides ways to compensate for the costs of utility bills and electricity.

Search for wood suppliers

To obtain sufficient quantities of raw materials, you should pay attention to local woodworking enterprises and sawmills. They can provide the factory with wood without delaying delivery deadlines.

It may happen that there are no sawmills or wood processing plants in the region. Then you will have to look for suppliers in other cities. To do this, you need to get acquainted with the offers on the Internet, read reviews, talk by phone with managers and make the final choice.

“We recommend reading: How to choose a reliable supplier for your business.”

It is difficult to name the price that the supplier will have to pay at the initial stage. Because everything depends on the supplier itself, the chosen region and a number of other factors.

Step-by-step instructions for making furniture with your own hands

I have been designing cabinet furniture so that people can make it with their own hands for quite some time now, remotely. Based on the questions that I get asked every time, one conclusion can be drawn - in order to make furniture with your own hands, step-by-step instructions are simply necessary . Off the top of my head, here are the questions I usually hear:

- Do you only do the design or will we also discuss where the shelves will be inside?

- Will you give us cut cards so we can order detailing?

- Will the cards indicate the holes needed for assembly? Who will make them?

- How will I know what accessories I will need to buy and what else I will need, will you tell me everything?

- Will there be drawings for assembly, or just a general design that you will draw for us?

The questions, in general, are understandable and logical if they were asked in the same sequence that I listed. This is usually not the case. Usually people are worried about how the most difficult stage will happen. And all other stages, no less important, are unconsciously “lost” from attention. This shouldn't happen. If you do not follow the step-by-step instructions, the process of making furniture with your own hands will turn into a chaotic and uncontrollable process. It’s not difficult for me to give out the whole heap of documentation. But, as practice shows, an unprepared person will simply get confused in it, abandon the very idea of somehow saving money and do everything himself. But in fact, you just had to stick to consistency. As they say, “appetite comes with eating.” It’s the same with furniture - it’s enough to start consistently taking certain actions and many frightening things will become understandable and elementary.

Recruitment

A small furniture factory will need:

- Director, whose role can be the individual entrepreneur himself or one of the founders of the LLC.

- Accountant or outsourcing specialist.

- Account Manager.

- Designer and designer.

- Production foreman.

- Support workers.

- Machine operators.

- Workshop workers who will be involved in direct production and assembly.

It will cost about 300,000 rubles monthly to pay a staff of 12 people. If it is a small company, then 4-5 people are enough.

What to look for when choosing a room

The following criteria should be followed:

- whether the planned volume of output is large;

- how large the equipment is planned to be installed;

- what is the mechanism for purchasing and storing raw materials, what size warehouses will be required to store them;

- will the finished furniture be stored in warehouses or will it be produced for sale;

- how many jobs are planned to be created?

For example, if a business plan for the production of kitchen furniture contains a guideline for the production of serial products, a small workshop will be sufficient, which will be located in a small area, possibly under a lease agreement.

However, you should not underestimate the importance of compliance of the selected premises with current standards and rules. Thus, it is necessary to comply with fire safety requirements, have regulated communications, maintain microclimate parameters, equip areas for working with customers, staff work areas and sanitary rooms.

Furniture storage is a process that depends on internal and external weather factors. High humidity should not be allowed; it is advisable to ensure the air temperature in the room within the range of 18-20°C, protect materials from bright sunlight, etc.

When choosing a premises, it is important that it has convenient access roads and equipped areas for unloading and loading large cargo.

In some cases, they also resort to drawing up a business plan for a furniture store with free exhibition space.

Marketing plan

Getting started without a clear marketing plan means putting yourself at risk of going out of business within the first year. Therefore, it must be taken care of long before the opening.

Here are some marketing strategy tips.

- It is worth selling finished furniture in all available ways: through an online store, retail, supplying products to furniture stores for subsequent sale.

- It is imperative to participate in all tenders from local government organizations. Everyone needs high-quality furniture: educational institutions, healthcare institutions, kindergartens and homes.

- On the territory of the enterprise, in the administrative premises, a separate room should be equipped for presenting your products to potential wholesale buyers.

- It is effective to attract attention to the company by sending commercial offers to business centers, banks and other organizations in need of office furniture.

- The factory must have an official website and groups on social networks. For better effect, you can run contextual and targeted advertising. This will help you receive more applications from the Internet.

- When promoting a company, it is advisable to use traditional advertising tools: billboards, banners, banners, leaflets, advertising in newspapers, radio and TV.

All ways to promote a business are good. The main thing is to prove to the consumer that the product being produced is truly of high quality. To do this, you can significantly reduce prices for the first batch of products in order to get feedback from customers.

How much does it cost to start producing cabinet furniture?

So, it has already been calculated above that about 1,500,000 rubles will be spent on equipment and tools. Renting a 500 m2 premises will cost 200,000 rubles. Employees need to allocate 300,000 rubles for salaries.

In total, opening an average furniture factory will cost 2,000,000 rubles. And this does not take into account the cost of raw materials, which depends on the supplier himself.

If you plan to open a small production, where an individual entrepreneur will do it himself, then the above amount can be divided in half or three.

Business profitability is 40%. Payback - 8-10 months. The net monthly profit of an enterprise can start from 500,000 rubles.

«

Fillers

Upholstered furniture has also been influenced by progress and has undergone significant changes. First of all, innovations affected fillers.

Air

Air is one of the most used fillers for mattresses and poufs. Not a single material can compete with it in terms of cheapness and lightness, which makes it a favorite in this area.

To successfully use air fillers, it was necessary to improve the structures themselves, which previously had welded seams. Such seams on thick rubber or PVC quickly came apart even with careful and careful use. The load affected especially quickly when used by people with large weights. If you consider that such structures were practically not repaired, then you can understand how unjustified their acquisition was.

At the moment, seamless technology has been mastered, which has eliminated all previous shortcomings. Models produced on the modern market have a warranty period of at least 10 years.

Another useful feature is the ability to adjust the internal pressure, which allows you to change the rigidity of the product and adjust it in such a way as to meet the individual requirements of each customer.

Sintepooh

Filler in the form of light siliconized fiber made from artificial raw materials is very popular. There are several reasons for this:

- it springs perfectly and restores its original shape after deformation;

- does not interfere with air circulation;

- has low thermal conductivity;

- not afraid of getting wet;

- lightweight and non-toxic.

At the moment, it is actively used to fill decorative pillows, backs and armrests.

Main business advantages and possible risks

In conclusion, let us pay attention to the advantages and possible risks of the described business.

Advantages

- High and stable demand.

- Small investments at the start - you can start small production even in your garage.

- A business can work for a wide target audience, while simultaneously carrying out retail and wholesale sales.

- Relatively fast payback - you can return the money invested in the business in less than 1 year.

Risks

- High competition in the niche - new businesses are constantly opening, so there is always a chance of losing market share.

- Suppliers of raw materials may increase the price, which will increase the cost of production.

- Production is completely dependent on electricity supply. Therefore, in case of any problems in the electrical network or at substations, work will be stopped, which may disrupt the delivery time of products to customers.

The production of cabinet furniture is an excellent option for business. If you don’t have the money to open a full-fledged enterprise, then it’s enough to start small - do everything to order in your garage or in a country house. As soon as the first sales begin, money and prospects for further development will appear.

«

New interior approaches

At the peak of popularity is the eclectic style, which appeared as a result of collecting furniture from different eras and countries. In addition, symbiosis in the functional direction is popular; the traditional combination of functions has reached a fundamentally new level. One element can easily combine the functions of a bed, a sofa, a pouf and even a newspaper table. Moreover, each incarnation will be different in appearance, but not inferior in elegance of design. The ability to change sizes within one product is increasingly welcomed, which is especially important in conditions of limited space.

Many mobile elements are equipped with remote control. In this way, roll-out drawers of tables or cabinets, opening shelves, etc. are activated.

The technologies of radial and radial sliding wardrobes allow you to hide a sleeping area during the day and free up a huge amount of room space. Such solutions are already being specifically requested by buyers, especially residents of small apartments, since they allow them to actually increase the effective square footage of the premises.