prev-post

Previous article

Making a bedside table with your own hands

The versatility of furniture is as important as its reliability, safety, visual appeal and ergonomics. The ability to move an object in a room without much effort is a big bonus when it comes to optimizing your work and living space. An element such as a roll-out cabinet is an important part of the furniture content of a room with an equipped workplace, which performs a variety of functions and can be easily transported.

Construction type

A cabinet for papers is an auxiliary element of cabinet office furniture. How to place it in a room to increase the functionality of the workplace and ergonomically arrange the space? There are several main configurations of cabinets:

- ✓ Stationary. Stable, does not require frequent movement. Has high capacity. Helps in zoning office space.

- ✓ Roll-out. The mobile office bedside table can be easily moved and placed under the desk, allowing quick access to drawers.

- ✓ Attached. Forms a single composition with the table, increasing the usable area of the tabletop.

- ✓ Mounted. Attaches to the bottom of the table top. The design of the table and hanging cabinet allows it to be mounted both on the left and on the right. Such office bedside tables, as a rule, have no more than two drawers and one niche.

This is interesting: The nuances of choosing a corner bedside table, types of designs

Facade

The cabinet is an easy-to-use item that does not require additional mechanisms. When choosing this piece of furniture, criteria such as aesthetics, capacity and ergonomics come to the fore.

Each element of the office bedside table carries a functional load. This way you can save space due to the facade. There are closed and open cabinets. The advantage of the former is that household items and stacks of documents are hidden from view. This gives the workplace a neat appearance. Open fronts, in turn, make it possible to quickly take things off the shelf.

There are several types of closed facades:

- ✓ Boxes. 2-3 drawers are built into the office cabinet under the desktop. Such cabinets are usually from 53 to 56 cm in height. Office side tables with drawers are higher (4 drawers - 75 cm) and are often equipped with an additional open niche. The drawers use a pull-out mechanism. Side guides with rollers are attached to the bottom. To pull out the drawer, pull it towards you using the handle using little force. Do not put too many things in the nightstand - overloading the drawers causes the rollers to come out of the grooves and the boxes to warp.

- ✓ Doors. The doors are attached to the body with furniture hinges. Despite its simplicity, this facade is considered one of the most durable. To increase the service life of an office cabinet with doors, treat the hinges with care. Remove obstacles in front of the cabinet, then you can open the doors freely.

- ✓ Coupe. Modern and most ergonomic mechanism. Due to the sliding panels that cover the niches of the cabinet, it looks compact and aesthetically pleasing. Adjustable feet compensate for uneven floors and the mechanism operates smoothly. This reduces the likelihood of breakage.

For open cabinet furniture and office bedside tables in particular, the principle of open shelving is used, when the user can freely take things from the shelf.

Cabinet structure

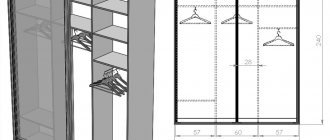

Any cabinet belongs to the category of cabinet furniture, in which the interior space is functional. Its body can accommodate several drawers. But, given that we are talking about a piece of furniture that cannot be higher than a table, there are usually no more than three such drawers that would be convenient to use. The cabinet can be attached, but in our case, preference was given to the more convenient option on casters.

Cabinet body dimensions

- You can see the most optimal dimensions of the product in the photo above. Well, the height of the drawers should be determined by dividing the height of the cabinet by three.

- Do not forget to take into account the necessary gaps between them, which are optimally 3 mm. That is, if you have three drawers, then you need to take into account four gaps: one at the top and bottom, and two between the drawers.

Hand drawn sketch

In any case, work must begin with a drawing on which all dimensions will be calculated and indicated. It will help not only to better navigate the work, but also to accurately calculate the amount of consumables and accessories.

Prices for various options for desk cabinets

Roll-out cabinet

Tips for choosing

Since the roll-out cabinet will be used almost daily, you need to choose it responsibly. In order not to be disappointed with your purchase, you need to know what criteria to consider. It is recommended to adhere to the following tips:

- The product must be made of high-quality material that is not afraid of mechanical damage and resistant to moisture. The best option is to choose a structure made of MDF treated with film or veneer.

- The attribute must be well assembled and not wobble.

- It is important that the fittings are made of steel, since this material is more reliable compared to plastic and aluminum. Metal handles and fixing elements are also desirable.

- Moving mechanisms must operate quietly, without making extraneous noise.

- It is important that the cabinet moves easily and smoothly, without any effort.

If the bedside table has a drawer with a lock, you need to check how well it functions. It is advisable that the kit includes not one, but several keys. If the design is purchased for a specific table, you need to accurately determine its dimensions.

High quality material

Good build

Serviceability of moving mechanisms

Easy and smooth movement

What kind of cabinet is this and what are its advantages?

A roll-out cabinet is a piece of furniture on wheels that can be easily and quickly moved around the room. Often the models are small in size, so they can be placed even in the smallest room, as long as the cabinet fits into the overall concept. Among the advantages of such furniture are:

- compactness;

- mobility;

- elaborate interior space;

- reliability.

Among the disadvantages, it is worth noting that the wheels may not be of the highest quality, so they may break. In addition, the price of such products is somewhat more expensive than classic cabinets. But an inexpensive roll-out cabinet is not uncommon, you just need to look a little longer. If you want to save a little, then you should remember the following: when choosing furniture, whether for an office space or for a home, you need to take into account several important characteristics: appearance, reliability, convenience and functionality. You should start with the dimensions.

What wheels are mobile bedside tables usually equipped with?

According to the rules, a review of the types of wheels will help you choose a rolling bedside table. The classification of such fittings is carried out according to a wide variety of indicators.

There are wheels that can turn while moving. With this furniture it is comfortable to perform maneuvers of varying complexity even in a smaller area. If you do not expect to frequently move the bedside table from one place to another, then non-rotating parts are perfect. Their advantage is considered to be quite high reliability and resistance to heavy loads.

By request, the next note will be on the topic - hi-tech TV stand. We believe you will like it.

The following options are used for fastening furniture wheels:

- screw fastening;

- sleeve;

- spider fastener with thread.

The rollers are installed to the lower horizon or to the end part of the sidewalls of the frame.

To prevent spontaneous movement of the bedside table as a result of a push or other influence, the wheel supports are equipped with a stopper. It is a lever that securely locks the furniture in the selected position.

Plastic or metal is used to produce rollers. The first type has the advantage of durability and reliability. And in order to protect the floor covering from damage, a rubber rim is provided, which also ensures noiselessness when moving furniture.

By request, the next post will be on the topic of a nightstand under a mirror in the hallway. We believe you will like it.

In most cases, plastic parts are used for models with low weight.

This is interesting: Rules for placing a narrow shoe cabinet in the hallway, the nuances of choosing it

What wheels can mobile cabinets be equipped with?

An overview of what types of wheels there are will help you choose the right rolling cabinet. The classification of such fittings is carried out according to different parameters.

There are wheels that can be rotated while moving. With this furniture it is convenient to perform maneuvers of any complexity, even in a small area. If you do not plan to frequently move the cabinet from place to place, then non-rotating elements are quite suitable. Their advantage is considered to be higher reliability and resistance to significant loads.

The following options are used for fastening furniture wheels:

- confirmation;

- sleeve;

- threaded bracket.

The rollers are mounted to the lower horizon or to the end part of the sidewalls of the frame.

To prevent spontaneous movement of the cabinet as a result of a push or other impact, the wheel supports are equipped with a stopper. It is a lever that securely locks the furniture in the selected position.

Metal or plastic is used to make rollers. The first type has the advantage of reliability and durability. And to protect the floor covering from damage, a rubber rim is provided, which also ensures noiselessness when moving furniture.

Plastic elements are usually used for light weight models.

Color scheme and design of the rolling cabinet.

A professionally selected rolling cabinet must combine all the requirements that experienced designers put forward for furniture. The main ones among these qualities are:

- style;

- main material of manufacture;

- color spectrum;

- similar to existing furniture or similar fittings;

- geometric parameters.

In the standard version, the rolling cabinet has a height of 640 mm, but designs higher or lower than the standard are quite common. The color scheme can be very diverse, ranging from cherry, oak, walnut and apple tree, to more modern and fashionable lavender, modern, pistachio and milky shades.

Types of wheels

An important part of the design of the mobile model is the wheels, which provide mobile properties. When choosing them, many parameters should be taken into account: installation method, type of rotation, material, design, permissible load level.

Attaching the rollers to the lower horizon is done using:

- bushings;

- confirmation;

- threaded connection.

The rotation function is presented in linear and rotary versions.

The first type moves only in one direction, which affects maneuverability. Such wheels are usually installed on massive objects that are not planned to be moved frequently. Design advantages: high strength, reliability.

The rolling cabinet is equipped with swivel casters. This will allow you to easily move the product even in a limited space, without fear of collision. Most wheels are equipped with a stopper. It makes it possible to fix furniture in a certain place.

The wheels are made of metal or plastic.

The metal body is made of aluminum or steel, with a rubber rim attached to the top. The advantages of such products are as follows:

- withstand heavy loads;

- do not spoil the floor covering;

- move softly and silently.

The plastic version is not designed for heavy furniture. Even the most durable plastic sample will not withstand heavy loads and will quickly collapse. However, plastic rollers are affordable and can be easily disassembled, which allows you to replace damaged parts yourself.

Simple recommendations will tell you how to choose the optimal type of rollers for a cabinet.

- The expected load level should not exceed the specified tolerance. Otherwise, the wheels will quickly fail.

- Furniture design. The wheel system is selected in accordance with the appearance of the cabinet.

- High quality material guarantees long service life.

- Reliability of fastenings. The rollers are firmly fixed to the bottom of the cabinet and do not create strong friction during movement.

- No noise. Moving furniture should be done smoothly and without any extraneous sounds.

- Rotation function. The rotating design, although more expensive, will allow you to maneuver in a small area and protect the product from damage as a result of a collision with other furnishings.

The principle of assembling the box

A box without a front element, which is assembled first, consists of a bottom with three walls screwed to it. In factory cabinets, the bottom is made of hardboard (hard fiberboard). This material is chosen not because it is better, but because it is cheaper in mass production.

1. When working independently at home, it is much more convenient to use the same material for making the bottoms as for the walls - 16 mm thick laminated chipboard. One sheet, the area of which is about 4 m², is enough for the entire bedside table.

Drawer body

Fastening the side walls of the box to the end class=”aligncenter” width=”534″ height=”340″[/img] Fastening the facade to an eccentric screed

2. Such thick sheet material is used to ensure that the connections of perpendicularly located elements, which are made on confirmations, are as strong as possible.

3. Confirmats are so-called euroscrews with zinc coating, which have a blunt shaft at the end and a countersunk head. These hardware are very convenient because they do not require scrupulous precision markings.

Note. Although the confirmations go into hiding, the places where they are installed remain visible. This is unacceptable for facades, so for their fastening you should use eccentric ties, for which you need to very accurately mark.

See below for how this is done.

Connection details

For clarity, we offer instructions in pictures, and we will mention the necessary tool during the comments.

Table 1. Assembling boxes

| Steps, photo | A comment |

| Step 1 — Device for marking under the screed | For accurate marking and drilling for the eccentric, it is necessary to use a special jig. |

| Step 2 - Marking for fastening | Taking into account the size of the fastener and the location of the hole for it, markings are made using a square. |

| Step 3 - The principle of working with the conductor | Having made a mark at the required distance from the edge of the workpiece, place the jig on it and align the tip of the triangular pointer with the pencil mark. |

| Step 4 - Drilling the End Hole Through the Jig | Holding the jig firmly in a given position, drill from the end side of the facade part through a hole specially designed for this purpose. |

| Step 5 - Marking the Second Hole | Now insert a drill bit into this hole to center it. Take an awl, and through the marking holes in the jig, mark a point for drilling on the rear plane of the drawer front. There are several such holes on the jig, the choice of the desired one is made in accordance with the length of the eccentric leg. |

| Step 6 - Drilling a hole for the eccentric head | A blind hole with a diameter of 15 mm is required for the eccentric head, for drilling which you need a wood cutter (Fostner drill). |

| Step 7 - Installing the Cam in the Hole | The eccentric head can be easily inserted into the resulting wide hole, and its rod will be inserted into the side hole. In this way, parts for all boxes are prepared, after which you can begin assembling them. |

| The bottom is placed on the table, and the back wall is screwed to it first... |

| Step 9 — Jig for drilling holes for fasteners | ...then the side ones. To mark the drilling sites for fasteners, you need a different type of jig (you can see it in the photo), but the principle of working with it is still the same. |

| The fastening of one rear and two side walls is carried out using European screws. |

| Screw in the confirmations using a screwdriver. |

| Step 12 - This is what the finished box will look like | After attaching the walls, all that remains is to screw on the facade. But this is done after all the drawers without front walls have been installed in the cabinet body. For now, just a fitting. |

The next stage is the installation of running gears.

Installation of guides

It is better to assemble the cabinet body and install roller mechanisms on the racks after all the drawers are ready. After all, your production is not mechanized, and there may well be errors in size. Therefore, the drawing is a drawing, and markings on the racks for fastening the runners must be done by measuring the height of the front elements of the boxes in fact.

Table 2. Installation of guides

| Steps, photo | A comment |

| We decide on the position of the running mechanisms, which can be either from the bottom of the side wall of the box, or from the top or in the center. |

| Make markings on the side of the box. |

| Mark the distances between the rollers on the stands of the cabinet. |

| Step 4 - continue marking | Draw the installation lines for the reciprocal part of the roller mechanism. |

| Step 5 - Disassembling the guide into two parts | The roller mechanism consists of two parts, which are disconnected from each other by pressing the lever. One part is attached to the drawer, the other to the stand of the cabinet. |

| Step 6 - Marking the Rail Attachment Points | Apply the guide to the marking site, and mark the attachment point in the center of the hole, first with a pencil, then with an awl. |

| Apply the screw and tighten it. Then similarly fasten the counter parts of the runners to the sides of the drawers. |

Note. The guides are attached through oblong vertical holes.

Which hole to mount it in?

General selection criteria

An analysis of a number of criteria will help you choose the appropriate model of a roll-out cabinet. These include:

- dimensions:

- execution material;

- façade design and arrangement;

- internal filling;

- reliability of the fittings.

Frame

The product frame includes the following elements:

- table top;

- bottom;

- sidewalls;

- back panel;

- facade;

- Rollers serve as supports

As for the dimensions, the mobile cabinet has modest dimensions, and their choice is determined by the installation location. Average size indicators are within:

- height from 50 to 65 cm;

- width from 40 to 60 cm:

- the depth is 45-50 cm.

The model combined with a sink in the bathroom reaches a height of 86-93 cm.

The bedside table is comparable in height to the bed, otherwise it will cover part of the room.

A product that is slightly lower than the working surface (approximately 110-115 cm) is suitable for the kitchen.

Combined with the desktop is a model that slides freely under the tabletop.

For the manufacture of roll-out cabinets, traditional materials are used. Let's look at what options there are, what their advantages and disadvantages are.

- Tree. Environmentally friendly, beautiful, reliable material designed for a long service life. Cons: heavy weight, significant cost, sensitivity to moisture and temperature changes. Wooden models should be chosen for the bedroom, children's room, and office.

- Wood boards are more affordable in terms of price, will delight you with a variety of exterior finishes, but are less durable. The best performance is demonstrated by products made from MDF. When finished with veneer, a complete illusion of natural wood is created.

- Metal structures are reliable, resistant to aggressive factors, but look too formal in a home environment. Therefore, a metal frame is often combined with wood, glass, and plastic.

- Plastic gives the product lightness, has the ability to take interesting shapes, and is painted in different shades. It is not afraid of moisture, it is easy to clean. Disadvantages: fragility, sensitivity to mechanical stress.

Filling

The internal content is selected based on the purpose of the furniture.

- The bedside table is equipped with drawers and shelves that are hidden behind the door. A useful element will be a retractable tabletop, which increases the working surface, and lighting. The latest addition will help you find your way in the dark, acting as a night light.

- In the bathroom, part of the cabinet space can be occupied by a mesh container intended for dirty things.

- The kitchen modification is complemented by a stand for drying dishes, hooks for holding utensils, etc.

- For work and study, it is best to choose a cabinet with several drawers, which will allow you to organize the storage of documents.

- The interior of the hallway will be complemented by a model with a soft surface, a drawer or an open shelf and a shoe rack.

Accessories

Reliable operation of the product will be ensured by high-quality fittings.

The drawers are equipped with guides of different designs.

- The roller type has an affordable price, is easy to install and handle, and does not require additional maintenance. The disadvantages include: limited visibility of the contents (no more than 2/3), increased noise level, low load level (no more than 25 kg).

- The ball version will cost more. It is designed to hold an impressive weight (up to 60 kg), demonstrates durability, operates smoothly and quietly, and allows the drawer to be pulled out completely. Often supplemented with a closer and damper. The device ensures gradual closing of the drawer without human effort.

In addition to retractable structures, the cabinet is complemented by hinged doors. The sash is attached to the frame with furniture hinges. To open it, just pull it towards you. The width of the door is limited to 65 cm. More massive doors will cause distortion of the product, breakage of the fittings and destruction of the material at the attachment points.

Such a system is considered reliable and will last for decades. The shutter moves 130° and provides good visibility. Opening and closing of the cabinet occurs without unnecessary noise. The disadvantage of the swing structure is the presence of free space in front of the facade.

Facades

The design of the facade determines the appearance of the product. According to their design, they are divided into solid and frame.

The first type is made of one material. Its advantages: lack of joints. Cons: simple design, heavy weight. The surface is varnished, painted, laminated, covered with film or natural veneer. Curly overlays add decorativeness.

Frame facades are used more often. In this case, it is possible to combine different materials, which gives room for imagination and allows you to imitate expensive samples. The design consists of a frame and an insert. The frame has grooves for installing the lining. The latter is fixed with glue and glazing beads.

The frame is made of wood, MDF, chipboard, aluminum.

For insertion use: plywood, glass, mirror, plastic, wood, wood boards.

The panels are available in the following versions:

- flat;

- volumetric;

- typesetting;

- figarea;

- floating

A cabinet on wheels provides a good opportunity to arrange the interior in accordance with your needs, change the composition without extra effort, and organize a convenient storage system.

Nuances of choice

The issue of selecting furniture requires a careful approach, especially if it will be used daily and often. There are a number of basic recommendations, following which you can safely count on a quality purchase:

- the quality of the material must be high. The most expensive and desirable material is wood. It is environmentally friendly and pleasant both in appearance and to the touch. MDF is cheaper, but no less safe. This is the most common replacement for solid wood, used everywhere. By the way, MDF is valued by assembly craftsmen for its ease of processing. MDF must be glued, covered with veneer or PVC film;

- the assembly of the structure should not raise doubts. This means that the cabinet parts are attached quite rigidly and do not move independently of each other. All panel seams must be smooth and not create unwanted gaps. The drilling areas for MDF panels are treated with glue.

- The quality of assembly of a given element of a furniture set also depends on the fittings. Metal parts are selected from steel or aluminum. The second is more expensive, but lighter and more durable. The smelting of metal handles, hooks, and other high-quality parts is carried out without side formations on products in the form of burrs or unpolished surfaces;

- high-quality moving mechanisms operate quietly, without creating unnecessary sounds such as creaking or grinding. The smooth operation of the retractable shelves indicates their convenient further use. It is very important to notice intermittent movements immediately, because interference in the path of the rollers will quickly damage them;

- the movement of the cabinet on rollers should also be easy and smooth;

- you need to make sure that the roll-out cabinet with a lock closes securely enough and comes complete with several keys;

- When installing a cabinet under the table, you need to accurately measure all the data on the second one.

Regardless of whether the furniture meets the above criteria, you can always request documents from the product supplier that will confirm the quality of the product. Before purchasing a cabinet, you should inquire about the existence of spare parts for it in case of an unexpected breakdown.

What to look for when purchasing.

When purchasing a rolling cabinet, pay special attention to the fittings. This can be a weak point for every manufacturer. Take the trouble to clarify the origin and name of the company that supplies components for creating the cabinets. Another important element is the joints of wooden surfaces. This directly determines how well the rolling cabinet will function and not lose its performance characteristics during operation.

In our catalog you can choose and buy rolling cabinets of various shapes and colors.

What rooms is it suitable for?

If you purchased a roll-out table stand, it will be perfect for decorating your workplace. And in the drawers you can easily hide important documents, papers and other office supplies. However, if necessary, they will always be at hand.

If you want to purchase a roll-out cabinet for the hallway, then make sure that there is a soft seat on the tabletop. In this case, this cabinet can be used as an additional seat. And in the drawers you can store shoe care items, an umbrella, keys and other small items.

In the bathroom, a roll-out cabinet will also not be superfluous, because thanks to its mobility, the cabinet can be moved to any place, and it will not get in the way in a small space. And in the many drawers you can store soap accessories, spare clothes and a towel. Designers recommend choosing a white cabinet for the bathroom, since it can suit any interior and design.

Advantages and disadvantages

A cabinet with roll-out drawers is designed to optimize the workspace through its rational use. Its compact design fits perfectly into any interior, you just need to choose the right product design. We will tell you what positive aspects this piece of furniture has:

- Compactness is the first and one of the most important advantages of a roll-out cabinet. It is designed so as not to attract attention and to be maximally involved in the work processes of its users. This product hides perfectly in a niche in a table or other furniture, and performs the simple functions of ordinary drawers;

- mobility is the second equally important plus, allowing you to manipulate the location of the cabinet at will. Instead of using it as part of a desk or as an integrated element into a furniture wall, it is often installed as a separate cabinet.

- The presence of drawers allows you to use the internal space as efficiently as possible. Basically, acting as a bedside table, such an element has dimensions suitable for at least A4 documents. This allows you to place any documentation, stationery and other necessary things inside the cabinet. A roll-out cabinet with 4 drawers is very common;

- the presence of a top surface adds functionality to this product. On such a platform you can put anything from your favorite photographs to office equipment;

- A roll-out cabinet with a lock will safely store important documents and things.

It is worth noting some disadvantages of a roll-out cabinet:

- a desk and a stand separately are more expensive than a desk with drawers. This is primarily due to the high consumption of materials. If you order a cabinet for a table that has already been delivered, it is better to use the services of a specialist who will take accurate measurements;

- Roller supports are less durable than regular legs, so you should be careful when installing expensive equipment on the surface of the cabinet. It won’t be entirely pleasant if the bedside table sags under the weight of the water cooler;

- Constant transportation requires careful handling of the cabinet. Otherwise, both it and the furniture to which it is attached quickly become damaged and lose their external qualities.

Completion of the assembly stage

The principle of assembling the cabinet itself is not very different from making a drawer. The sides and rear wall are attached to the bottom in the same way. The front walls of the drawers will form the façade - these are what we will be installing now. To do this, the body of the cabinet must be assembled without the back wall, and the drawers must be put in place.

Table 3. Assembly

| Steps, photo | A comment |

| Step 1 - Assembling the Case | Once all the drawer slides are installed, you can assemble the box pieces together. The connection is made on confirmations. |

| Step 2 - Installing the Drawers | Place drawers without fronts in their regular places and check that they slide out easily. |

| Step 3 — Marking the façade for drilling holes for the eccentric | Now you can start hanging the front strips on the drawers. Place the workpiece face down, and use a square to determine the points for fasteners. |

| Punch the hole with an awl over the pencil mark. |

| Step 5 - Drill the holes | The holes are drilled blind, the diameter should correspond to the diameter of the tie, and the depth should correspond to the length of its thread. |

| Step 6 - Screw in the eccentrics | The ties are screwed into the holes on both sides up to the limiter. |

| The eccentric legs are aligned with the holes in the ends of the side walls of the box, and the front strip is installed in its place. |

| Step 8 - installing the eccentric head into the hole | Next, eccentric heads are placed in the wide side holes... |

| ... after which they need to be tightened with a screwdriver. |

| Install all the fronts on the drawers in the same way, mount the back wall - and, in principle, your cabinet is ready. |

Attention. Do not forget that before starting assembly, the ends of all workpieces must be covered with melamine edge. It is sold already with an adhesive layer; all you have to do is apply it to the cut and iron it with a hot iron.

In conclusion, all that remains is to screw the wheels to the bedside table - to make it convenient to move it, and install the handles on the drawers. If desired, the perimeter of the product body can be decorated with a wooden baguette or polyurethane molding.

Small-sized apartments exist not only in old Khrushchev-era buildings; completely new housing projects, designed for the poorer category of our fellow citizens, also save on passerby space. The industry takes into account the situation in the housing market and produces small-sized but very functional furniture specifically for such situations. In a special article you will find tips on choosing a cabinet for a small hallway, as well as instructions for assembling a door cabinet.

Video - How to make a cabinet with drawers

Manufacturing materials

An important issue in choosing furniture is the material from which it is made. It must meet a number of criteria to satisfy the designer's needs. These measures concern its safety, its durability, price and external data. Let's look at the main materials that are used to construct roll-out bedside tables:

- solid wood is a high-quality and environmentally friendly material that is valued for its noble appearance. Wood is rarely used in the manufacture of roll-out cabinets, since this type of furniture is mainly used in offices, where the cost of its filling plays an important role in the arrangement. Wood is a fairly expensive product compared to other materials, so it is more suitable for making furniture for a personal office or for a personal workplace;

- Chipboard and MDF boards are the most common and inexpensive materials used to create most furniture elements. It is used very often for making shelves due to its low cost and light weight. The covering of MDF boards is often made in the form of a wooden surface, and serves as an affordable replacement for solid wood. Chipboard sheets are used as the back wall of the cabinet;

- The MDF sheet is covered with plastic and accessories are made from it, as well as elements of working mechanisms. Coating MDF with plastic guarantees the safety of the second for a long time, and gives it a more presentable appearance, for example, the structure of a wooden surface;

- metal parts are irreplaceable parts of the product, without which this furniture cannot function normally. Metal is primarily used to create fasteners that hold the structure, as well as working mechanisms and fittings, such as hinges, rails for drawers, handles, shelf holders, and closers. The roll-out cabinet with a lock is equipped with a steel closing mechanism;

- PVC film is also used to cover MDF panels to extend their service life.

It doesn’t matter what material is used to construct the roll-out cabinet, the main thing is its compliance with safety standards.

Wooden

Plastic

Chipboard

MDF

Material and dimensions

When choosing a roll-out cabinet with or without a lock, you must take into account what material it is made of. Not only the appearance of the structure, but also its service life and performance characteristics depend on this fact. Most often, for the manufacture of a roll-out cabinet with drawers, the following is used:

- Chipboard and MDF boards. These materials are considered the most common and budget-friendly. The coating of MDF boards often imitates a wooden surface, making the cabinet look beautiful and stylish. Chipboard sheets are used to produce the back wall.

- Metal. Durable and reliable material. A product made of metal will last for many years without deforming or changing its appearance.

- Solid wood. Natural environmentally friendly material. In the manufacture of roll-out cabinets, solid wood is rarely used, due to its high cost.

- Plastic. More often, MDF boards are covered with it, and elements of working mechanisms can also be made from it.

Roll-out cabinets are often made from the same material; combining different bases is practically not carried out. As for the wheels, they can be made of plastic or metal covered with a rubberized body. Fittings made from the second material are stronger and more reliable; they are often installed on large cabinets that have to withstand heavy loads. If an attribute is purchased for an apartment, it is better to choose a product that is equipped with plastic wheels, as they are softer and do not damage the floor covering.

Types of corner cabinets for kitchen sinks, their pros and cons

The wheels differ not only in the material they are made of, but also in size. Dimensions vary depending on the purpose and appearance of the product. Large metal wheels are more suitable for work cabinets. Options for the hall, bedroom or kitchen are often equipped with small fittings.

It doesn't matter what material is used as the base. The main thing is compliance with safety standards.

Chipboard

MDF Metal Solid Plastic

As for the size of the cabinets, this parameter depends on the purpose of the furniture and its location. So, for example, options for a bedroom often have the following dimensions: height - from 50 to 60 cm, depth - about 50 cm, width - from 40 to 60 cm. A kitchen cabinet can be up to 115 cm high. It is important that a person is comfortable use it, in particular, cook. The standard width of the kitchen variety is from 60 to 80 cm, depth – 60–65 cm. The dimensions of cabinets for the bathroom and offices depend entirely on the size of other furniture, for example, in the bathroom this attribute should be placed under the washbasin, without protruding beyond it.

Accommodation options

The furniture is designed to optimize space. Its correct location in the room will create a cozy atmosphere in the interior. If we are talking about the working area, then its rationalization by correctly arranging the filling elements will help increase the efficiency of any employee. In addition to meeting the needs of employees, during planning it is worth thinking about the clients who will come into the office. Here are some examples of placing a roll-out cabinet in the interior:

- under the table - this place for a roll-out cabinet is most often determined, since it turns out to be more useful here. Most of an office employee's working day is spent at the desk, so documents and accessories stored in the cabinet should always be at hand. Typically, such cabinets have four drawers. By pulling out the cabinet completely, you can install a printer, MFP on the surface, or simply put a cup of tea so as not to spill it on things on the table. The mobility of the cabinet allows you to experiment with the side of its location under the table, if the design of the second allows you to freely move large objects under it;

- Under the wall, roll-out cabinets serve not only as structures with drawers, but are also suitable as a table, for example, for flowers. The product, equipped with shelves instead of drawers, is closed with a door. It can store dishes, snacks, and a dish with cookies will sit perfectly on top;

- It is possible to locate the cabinet in a furnished niche of the office furniture wall. The usage pattern is the same as in any other case: installed in a closet, the cabinet serves as a storage unit for everything you need, and when pulled out, it also serves as a table;

- Near the sofa for clients, the cabinet is perfect as a table, at the same time storing things necessary for employees, or magazines for guests, which can be read while waiting.

Roll-out cabinet (mobile container) - drawing. - download

A simple mobile container, or a roll-out cabinet - we present a drawing for self-assembly. This is not a complicated product that a novice craftsman can assemble. Basalt wool can be perfectly stored in it.The container is made of 18 mm thick laminated chipboard. The ends of the facades, bottom and lid are treated with a 2x22 mm PVC edge, the ends of the supporting parts are treated with a 0.5x22 mm paper edge. For assembly we will need:

- Drill or cordless screwdriver.

- Iron.

- Stationery knife.

- Attachment for screws.

- Nozzle for confirmations.

- Drill for confirmations.

- Drill for pins.

- A tape measure, a pencil, and - preferably - a square.

No special room is required - you can assemble it in your apartment.

Of course, it is better if you have a garage. True, garage cooperatives are often disconnected from the power grid for non-payment. To avoid the inconvenience of power outages, you can use a cordless tool. The list of materials and accessories is given on the last page of the drawings.

The procedure for assembling a roll-out cabinet.

We print out the cutting map and go to a company that sells and cuts laminated chipboards. We are looking for a company where we can glue PVC edges at the same time. We order parts with PVC gluing and go for accessories. When all the parts and fittings are in the apartment, we assemble the cabinet in the following order:

- Using a regular iron, we glue the paper edge to all the parts where it is needed. We cut off the overhangs with a stationery knife and polish them with felt.

- We assemble boxes without fronts.

- We attach guides to them.

- We mark the places where the guides are attached to the sidewalls (the drawing is attached), and fasten them with 3x15 screws.

- We drill holes for confirmations and pins in the bottom and lid.

- We attach the back wall to the sidewalls and drill holes for confirmations in it, through the already prepared holes in the sidewalls.

- We screw in the confirmations.

- We do the same with the bottom.

- We insert taps into the holes for the pins that hold the lid of the cabinet, and by pressing the lid onto the cabinet, we transfer the center of the future holes to the lid.

- Drill holes for the pins in the cover.

- We insert the pins into the sidewalls and back wall, having first dipped them in PVA glue, then put a lid on them, also on the glue.

- We mark and drill holes for handles on the facades.

- We insert the drawers into the cabinet and attach the fronts with double-sided tape, which will allow them to be adjusted.

- When the fronts are exposed, we drill holes in the front wall of the drawer through the holes for the handles.

- We tear off the facades, remove the tape, put them in place one by one and screw on the handles; the handle bolt passes through the facade and the front wall of the drawer, connecting them.

- For reliability, we fasten each facade with two more 4x30 screws, from the inside, through the front wall of the drawer on the sides of the handle.

- The last thing is editing the videos. To do this, our roll-out cabinet is turned upside down, and the wheels are secured with 4x17 screws.

That's it, the mobile container is ready. Drawings include:

- The cabinet is roll-out in three projections, with numbered parts and dimensions.

- Side panel drawing.

- Detailing.

- Cutting map.

- Calculation of materials with approximate prices (total amount - 36 USD).

You can download the drawing of the cabinet using the link at the top of the page, available to registered users. To download files, first register or log in with your username.

Purpose and benefits

A roll-out cabinet is a design equipped with four wheels, which makes it mobile and allows you to move it to another place in a matter of seconds. Thanks to its compact dimensions, the product can be placed in almost any room; for this you only need to choose the right design. The advantages of the design include:

- compactness - due to its small size, the roll-out cabinet can be removed under the table or hidden behind other furniture;

- mobility – thanks to wheels the product can be easily moved;

- well-thought-out interior space - due to the presence of drawers, the cabinet can be used as a mini-wardrobe;

- reliability - as a rule, the top drawer is equipped with a lock, so that all things and documents will be safe.

As for the disadvantages, roll-out cabinets with drawers have practically none. The only thing that can be considered a minus is that they are more expensive compared to standard designs. In addition, the wheels of such products may break, but this usually happens if low-quality fittings are used.

Despite the fact that the main purpose of roll-out cabinets is the competent organization of workspace in the office, due to their functionality and convenience they are increasingly being installed in apartments. The product accommodates various office supplies, flash drives, disks, cords, adapters, chargers and other accessories, allowing the table surface to be free. You can also store photo albums, decorative items, and cosmetic accessories in the cabinet. If the product is large in size, you can place small household appliances in it.

CompactMobility

Well-thought-out interior spaceReliability

Varieties

Depending on the purpose and design features, roll-out cabinets with drawers are classified into several types. Depending on the type, the dimensions, design, and functionality of the product will differ. Cabinet options:

- Bedside. Such cabinets are made in compact sizes and rarely accommodate more than two drawers. Most often used for storing cosmetics, books, magazines.

- For documents. They are made from different materials, most often metal. Each drawer of the structure is equipped with a lock. Due to the specific design, such attributes are installed only in office premises.

- Kitchen. This bedside table is used to store food and dishes. If necessary, it serves as an additional work surface.

- In the hallway. The product is equipped with several open shelves and a drawer. You can store combs, elastic bands, accessories, and cosmetics in it.

- To the nursery. Often made in compact sizes, it has a non-standard bright design. Used for storing toys or educational supplies.

Advantages of a folding table-cabinet with drawers, criteria for choosing furniture

BedsideFor documents

Kitchen

To the hallway

To the nursery

Cabinets vary depending on the type of wheels. They can be rotating, non-rotating, or with a stopper. The last option is the most functional. These wheels not only move in all directions, but can be locked in a specific position if desired. Also, roll-out cabinets differ in the way they attach the wheels. The element can be fixed using a bushing, using a confirmat or with a threaded connection.

RotatingNon-rotating

With stopper

Material

Cabinet furniture for the office not only simplifies everyday tasks, but also helps maintain the corporate image of the company. Therefore, the quality of materials for office furniture is of particular importance. The body of the cabinet consists of several parts: lid (tabletop), sides/ends, facade, back wall, edge and bottom.

The most popular materials for making office cabinets are:

- ✓ Laminated chipboard (chipboard) - sanded chipboard and a paper-resin coating are used in the manufacture of the board. The topcoat may vary in color and texture.

- ✓ Fiberboard (fibreboard) – a material made from crushed compressed wood. The bottoms of drawers and the back walls for cabinets are made from fiberboard. The advantage of this material is that it is resistant to moisture, has antiseptic impregnation and increased strength.

- ✓ PVC (synthetic material) - furniture joints are covered with fiber. Thanks to this material, the wear resistance of the product and its resistance to damage increases. PVC fits perfectly to the ends of the chipboard and does not allow moisture to penetrate inside.

- ✓ Melamine coating – ribbon made of decorated paper. It is resistant to light, shock and temperature changes, non-toxic, and resistant to stains.

Filling

The filling system depends on the purpose of the product. Cabinets may have the following additional elements:

- Open shelves. They are equipped with both office options and products intended for apartments. Most often, decorative items, mobile phones, and tablets are placed on the shelves.

- Drawers. Used to store a variety of things. If a bedside table is purchased for an office as a desk, office supplies and necessary documents are stored in the drawers; the upper elements often have a lock. Bathroom or bedroom furniture is filled with cosmetics and hygiene products. You can also place small towels in the cabinets.

- Stands. As a rule, such elements are installed on cabinets intended for a desk. Typically they contain pens, pencils, and business cards.

- Metal baskets. Such filling is used only for attributes that are installed in bathrooms and kitchens.

Internal lighting is often installed on roll-out cabinets for bedrooms and bathrooms. Thanks to it, you can easily find the thing you need without turning on the main light. Lighting is not installed in office bedside tables.

Open shelves

Drawers

StandsMetal baskets

Photos of mobile stands

<

>

A mobile cabinet is a quick and easy way to change the usual arrangement of furniture and introduce something new into the interior. At the same time, the product serves as a storage place for various things. The choice of model depends on the overall design style of the room, the level of load, and the characteristics of the room.

How to place it correctly

Roll-out cabinets are designed for rational use of space. How cozy the atmosphere of an office or room will be depends largely on the location of the item. If a product is purchased for an office space, it must increase comfort during work. If the roll-out cabinet is placed correctly, the employee will be able to quickly find the necessary documents and supplies, which will save working time. Another mandatory condition when arranging such furniture is that it should not interfere with clients. There are several options for installing the product:

- Under the table. This is the standard option. The desk is constantly used by office employees, so documents and stationery should always be at hand.

- Under the wall. In this case, the attribute functions as a design with drawers and can also be used as a table.

- In a niche. The cabinet serves as a place to store everything you need. If desired, it can be pulled out, in which case it can be used as a table.

- Near the sofa for clients. It is used as a table and at the same time holds things important for workers.

Functionality and content of office cabinets, requirements and nuances of choice

Under the table

Under the wall

In a nicheNear the sofa

Types of mobile cabinets on wheels

The cabinet on wheels is functional and practical. It can be used in any room: bedroom, kitchen, study or nursery, hallway, kitchen. The purpose of the product and the features of the model are determined by the installation location.

Bedsides for the bedroom

The bedside design is intended for the bedroom. It is usually located at the head of the bed; the internal volume is used to store useful little things. A table lamp, clock or decorative items are often installed on the top surface; you can leave a book and a mobile phone. Its tabletop is used during morning tea, for working with a laptop or tablet. It’s easy to move the bedside table to another part of the room. The presence of soft upholstery turns the product into a comfortable ottoman, which will serve as a place for clothes or allow you to perform caring procedures and apply makeup while sitting in front of a dressing table with a mirror.

Office desktop

Equipping a desk in an office or nursery requires the presence of a mobile cabinet. It slides under the countertop or is installed next door. In the second case, the upper horizon is used for office equipment. Drawers will allow you to keep office supplies and work documents at hand and not clutter up the desk surface.

Under the bathroom sink

By the way, the roll-out model will be needed in the bathroom. The product is installed under the sink. This arrangement reliably hides plumbing communications, provides quick access to pipes in case of leaks, and greatly simplifies the cleaning procedure. The internal compartment near the drain siphon will become a place for storing household chemicals, and adjacent compartments will be suitable for clean towels and dirty things. All zones must be separated by partitions to prevent unwanted proximity.

Kitchen

The roll-out cabinet is for the time being hidden under the common countertop, so its height is slightly different from the dimensions of the kitchen unit. If there is a lack of space, you can always use an additional work surface for cutting food. Equipment in the form of drawers and compartments with shelves would be useful in the kitchen. Some models are complemented by a folding tabletop, which allows you to turn the cabinet into a full-fledged dining table.