Properly arranging a garage is much more difficult than a house, because there is much less space in it, and sometimes you need to place several functional areas at once. Everyone is different. For some, a motorhome is only a place to store seasonal items and care for the iron horse. And someone turns it into a workshop, a storage room for winter supplies, and arranges a personal space for relaxation and friendly gatherings. In each case, various homemade products for the garage allow you to seriously save money, and at the same time find useful uses for junk items.

You can do this if you don’t mind the money and don’t have the desire to create Source amd-comfort.ru

Making useful gadgets for your garage with your own hands

To carry out repair and service work, you will need to build an inspection hole in the garage with your own hands, the dimensions of which will correspond to the dimensions of the car, as well as a workbench for convenient work, plus equip the room with machines.

The basic set of tools and materials for creating a homemade garage workbench includes:

- boards and wooden blocks;

- fasteners and ties;

- plane and other woodworking tools;

- varnishing and carpentry adhesives;

- sandpaper and drying oil.

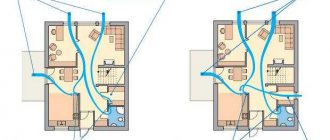

An example of placing useful devices in the garage: 1 - workbench with manual machines, 2 - racks and cabinets, 3 - table for various repair work, 4 - shelf for storing tires, 5 - inspection hole

Technology for making a workbench in the garage with your own hands: photos, drawings

The workbench consists of a table top and a base, as well as several clamping devices. The height of the workbench in the garage should be selected taking into account your own height. You can take as a guide the height of the kitchen table in the house, at which it is convenient to work. Be sure to make drawings to create a workbench for the garage with your own hands.

Garage arrangement: how to make a workbench indoors:

| Work stage | Details, size in cm | Mounting type |

| Assembling the tabletop | 20 boards (5x10x200) with grooves 2.5x2.5 in the 5th and 16th element (step 25) | Adhesive composition metal ties |

| Drying | — | — |

| Making legs (4 pcs.) | Block (10x10x80) with grooves for brackets on the front supports | Brackets |

| Assembling the base of the underframe | Frames (2 pcs.) made of boards (5x10) | Tenon connection to a depth of 2.5 cm and bolts |

| Fixing the side and rear support walls | Chipboard boards (thickness 10 mm) | Screws |

| Fixing the tabletop to the upper frame | — | Bolts |

Final processing involves impregnating the finished product with drying oil and opening it with varnish.

Recommendations for creating a viewing hole in the garage with your own hands

There are no specific sizes for a garage inspection pit. The dimensions of the car are taken as the basis.

How to make an inspection hole in a garage with optimal parameters:

The width is selected so that there is enough space inside to work. The size is limited by the distance at which the car's wheels are seated. Each wheel needs a small area to maneuver. The average pit width is 0.8 m. The length of the pit is limited by the length of the machine. 1 m should be added to this indicator. To calculate the depth, the height of the garage owner is used. Another 10-15 cm is added to it.

How to properly make a viewing hole in a garage using different materials:

| Material | Wall thickness, cm |

| Ceramic brick | 12-25 |

| Concrete | 15 |

| Building blocks | 20 |

The pit is dug taking into account the optimal width of the pit, the material chosen for the walls, as well as the thickness of the waterproofing layer. Stages of creating a pit:

- marking;

- construction of a pit;

- arrangement of the pit;

- construction of walls;

- lighting gasket.

For waterproofing walls, specialized hydrophobic impregnation is used.

Scheme of arrangement of the inspection pit: 1 - walls made of foam blocks, 2 - waterproofing, 3 - rubble masonry. 4 - corner size 50x50x4 mm

Making a garage press with your own hands

To create a press, a frame measuring 178x80 cm should be made from 4 pieces of metal pipes. These elements are connected by welding. It is recommended to be guided in your work by drawings, selected or compiled in advance. After this you need to install:

- retainer;

- removable stop;

- bottle jack (hydraulic).

You can use video materials to review the detailed technology for creating useful devices for the garage with your own hands. Such visual recommendations help you navigate the dimensions, master step-by-step instructions, and imagine what the finished structure should look like.

Manufacturing diagram of a hydraulic press: 1 - upper power platform, 2 - nuts, 3 - lower platform, 4 - studs with a diameter of 30 mm, 5 - lower thread of the studs, 6 - bottle-type hydraulic jack; 7 - base 20 mm thick

You can do the arrangement of your garage yourself. The list of useful devices does not end there. It can always be supplemented with any interesting ideas. The main thing is that the garage fully meets personal requirements in terms of comfort and convenience.

https://youtube.com/watch?v=D1BKvgCBg8Q

Required Tools

Different materials require a special set of tools:

- Metal structures require the help of welding and a secluded place without flammable materials to begin work. The parts of the metal frame can be fixed to each other using bolts and special angles.

- Wooden structures will not go far without self-tapping screws, a screwdriver and a drill. Wood products can also be fastened using special glue.

- Combined structures require special preparation. To cut structural parts, you will need a grinder or a hacksaw, since usually the metal component acts as a skeleton.

- Both wooden and metal materials that do not have anti-corrosion properties must be coated with special compounds. For example, for wood you will need varnish, and for metal an anti-rust solution.

The finished product is fixed to the wall using brackets and dowels, which can be driven in with precise blows of a hammer. An alternative to brackets are special anchors, which can be purchased at any construction market. With their help it will be easier to dismantle the structure if necessary.

Next, when attaching wooden blocks to the wall for a stationary shelving system, you will need the help of a level to align the boards and control the parallelism of the shelves relative to each other.

Ventilation

You need to understand that the microclimate of the room is an important part in maintaining the durability of the structure. Creating a high-quality ventilation system will eliminate various odors and prevent moisture from corroding the internal parts of vehicles.

The best option for creating ventilation would be to make two holes on the side of the gate, located opposite each other, and cover them with bars. On the opposite side, under the ceiling, two holes should also be made to create air mass permeability.

A more expensive method of ventilation is to equip the garage with electromechanical equipment and install exhaust pipes. Systems include electrical ventilation and blowing devices.

Ventilation of underground rooms is carried out using a ventilation pipe built into the wall. She is taken outside the room through the wall.

Video description

Another method of making a carrier is shown in the video:

It is important! In such a carrier, you can only use cool LED or energy-saving light bulbs.

For greater convenience, we recommend equipping your homemade garage with a device that allows you to remove the electrical carrying cable from the floor. Due to its large length, it often gets tangled underfoot, interferes with walking, and is easy to damage and receive an electric shock. Especially in cool weather when the cable loses its flexibility.

It is better to hang it from the ceiling on a steel cable stretched along a long wall. For this:

- screw two anchors with a ring-shaped head into the ceiling at opposite ends of the room;

- pull the cable between them, having previously strung several rings on it, which can be made from wire wrapped around the pipe;

- the diameter of the rings must be such that the carrying fork can pass through them;

- pull the cable through all the rings;

- if it is very long, attach a wire hook to the cable, on which the excess length will be hung.

The long cable is located under the ceiling and easily moves in the rings Source stroychik.ru

Power calculation and cable selection for a garage workshop

I began the implementation of my ideas by working out the general diagram of the electrical network of the garage-workshop (Fig. 7) and assessing the main current loads. When working alternately, machine tools and power tools consume a maximum of 2 kW, a welding machine (3 phases) - 5 kW.

I decided to use cables with only copper wires. Aluminum ones break after several kinks and, with the same cross-section, withstand 25-40% less current than copper ones.

If there is no marking on the wire, its cross-section can be calculated using the formula S = ND2/A, where S is the wire cross-section in mm2;

N—number equal to 3.1 A;

D is the measured diameter of the wire in mm.

The diameter of the conductor (without insulation) is measured with a micrometer or caliper. The cross-section of a flexible stranded wire is determined by the sum of the cross-sections of all wires included in the core. The conductors of the wires have standard cross-sections: 0.75; 1.0; 1.5; 2.5; 3.0; BP 6.0; 10.0 mm2.

If there are several simultaneously loaded conductors in one cable, then reduction factors are used. When calculating, the maximum permissible current passing through such a conductor must be reduced by approximately UP to %.

After calculating the current load, I entered the garage with a cable with four copper conductors with a cross-section of 4 mm2, protected by a 25 A automatic circuit breaker. The three-phase sockets were connected to a cable with four conductors with a cross-section of U mm2 (3 mm2 could have been taken), and the automatic circuit breaker was used at 16 A. Blocks sockets on the walls (maximum current - 10 or 1 bA) were powered by a cable in two 2.5 mm2 cores. I connected the socket blocks on opposite walls of the garage to different phases. The lighting was carried out with a cable in two conductors with a cross-section of 2.5 mm2 and protected by a 10 A automatic circuit breaker. The three-phase meter on the panel is rated at 20 A.

Ventilation

Owners of personal vehicles and garages built for storage sometimes evaluate the operation of such an important system as ventilation with excessive recklessness. But the creation of conditions for maintaining cars, spare parts, tires, and products in the garage largely depends on the movement of air flows. Properly organized ventilation in the garage becomes a prerequisite for providing the necessary clean air to both the owner and movable property. Also responsible for removing toxic volatile compounds and excess moisture and dust

A properly organized air circulation system in the garage is the most important component of indoor comfort.

The structure of the ventilation system must be developed at the planning stage, and functional openings must be made in the walls of the garage during the construction of load-bearing structures. It is important to consider how many floor levels there will be, the expected number of cars, as well as the size of the room. The owner chooses an effective and economical method, which is determined by the type of system with the assigned tasks. The garage can be equipped with the following types of ventilation:

The garage can be equipped with the following types of ventilation:

- Natural ventilation system. It is based on the laws of aerodynamics and the movement of air masses without restrictions.

- Combined ventilation in the garage takes as its basis the rules of natural ventilation in combination with the use of mechanical devices to stimulate the movement of air masses.

- A mechanical ventilation system in the garage, which is carried out using special installations to stimulate the exit and entry of air masses.

Profitability of production

The markup on finished products is determined by many factors: the policies of competitors, the cost of materials and even the solvency of the buyer. In the middle price category, 80–100% is usually added to the cost of the product; budget furniture is sold with a markup of 120–150%, and for luxury furniture this figure is 50–65%. For the calculation part of the business plan for the production of cabinet furniture, you can give an example of pricing for a kitchen 2.5 meters long:

Cost calculation

| Name | Price, rubles |

| Laminated chipboard | 2 220 |

| Uncover | 560 |

| Fiberboard sheet | 350 |

| Edge | 720 |

| MDF facades | 5 100 |

| Tabletop | 1 650 |

| Decorative plinth | 120 |

| Skirting edge | 80 |

| End strip | 180 |

| Washing | 1 500 |

| Dish dryer | 150 |

| Gas lift | 70 |

| Pens | 100 |

| Railings | 280 |

| Lower supports | 640 |

| Drawer guides | 120 |

| Door hinges | 130 |

| Glass | 180 |

| Total: | 14 150 |

Such a kitchen can be made in 2-3 days and sold at an average market price of 32 thousand rubles. When producing ten products per month, the enterprise's turnover will be 320 thousand rubles, and income will be 178,500 rubles, which, minus current expenses, is equivalent to a net profit of 71,225 rubles.

Based on calculations, we can conclude that with a short cycle, furniture production is a small business with a profitability of 28% and a payback period of 6–8 months.

Storage systems

After finishing, the second most important aspect of the arrangement is the organization of storage. Very often the garage is overflowing with all sorts of items - equipment, car tools, garden tools and just old things that it’s a shame to get rid of.

Tip: We strongly recommend that you take an inventory of everything in the garage and throw away unnecessary items - this will make it easier to organize truly useful and necessary tools.

Large garage storage system.

Obviously, the most practical and convenient storage option is to install shelving. They can be made narrow, but wide and tall, which is ideal for small spaces, for example 3*6 m.

Initially, we recommend planning the space - draw a layout to scale, mark the location of wiring, doors and windows, the location of the inspection hole and the parking area. Based on this, it will be easier to choose a place for a workbench, as well as the location and number of shelving.

Shelving made of metal and wood.

It is important to decide on the material of the shelving. It can be metal, wood or plastic

PVC structures have great advantages over other materials - they are light, durable (withstand up to 50 kg), not subject to corrosion and rotting, and durable. If this is a purchased modular design, you can change its configuration if necessary.

Idea: to reduce furnishing costs, it is quite possible to use ordinary household furniture in the garage. For example, cabinets, parts of a kitchen unit or modular walls that are outdated in appearance, but are in good working order.

To properly arrange your inventory, divide everything into the following groups:

Frequently used items, tools and equipment. It is logical to place them on open shelves so that they are always at hand. Rarely used items. It is better to place them either very high or in the lowest compartments of the rack. Small items

It is very important to organize the storage of small parts, since they are the ones who create a feeling of chaos and disorder in the room. Storage of work clothes. You should definitely allocate several shelves or hangers for a change of clothes.

Important! The distance from the car to the racks should be about 1 m - this will ensure free passage and access to all shelves. Read on our website: DIY garage shelves

Read on our website: DIY garage shelves.

If everything is quite clear with the arrangement of large items, then difficulties may arise when storing small items (of which there are a lot in the garage). To save small things, you can use a wide variety of unexpected systems. In the photo below we will show how you can simply and beautifully arrange the inside of a garage with your own hands.

- magnetic tapes - will help in organizing various small metal items (drills, nuts, bolts, etc.). But if there are a lot of them, it is worth considering another option;

Magnetic tapes for small items.

plastic containers of different sizes - these are where you can store all of the above, sort them by size and purpose. Containers can be the size of a tin can or in the form of large plastic boxes; high lattices - great for storing narrow and long elements, such as cornices, pipes, fishing rods, profiles, etc.;

Metal mesh for storing long items.

vertical space - the outer parts of doors with hooks, perforated boards (pegboards) can be turned into highly functional organizers.

Use of vertical space.

brackets - allow you to store large items such as car tires and folding furniture.

Examples for inspiration

- A very useful and convenient shelf for power tools will definitely fit into your garage.

- A universal rack can be a replacement for several storage systems. Several sides, mobile, special hooks for securing things - convenient and practical.

- A universal wall will also replace several shelves, help to collect all the necessary equipment in one place and free up a lot of free space. This option is especially good for those who have a small garage.

- Racks for agricultural tools are an indispensable thing if rakes, hoes, shovels and other items that clutter up the space are stored in the garage.

- Sliding cabinets are convenient, economical and practical.

You can learn how to make shelves in the garage with your own hands from the video below.

Gates

When arranging a garage, it is important to pay great attention to what will connect it with the outside world. It is necessary to take into account all possible obstacles to entry into the garage for further installation of the gate. The gate, first of all, serves to protect the room from penetration, and also retains heat inside

The gate, first of all, serves to protect the room from penetration, and also retains heat inside.

Types of garage doors.

There are the following types of gate designs:

- Swing. The cheapest and simplest option.

- Lifting. The gates are lifted into a special collection box, allowing you to save space inside the garage and not take up space on the street.

- Multi-sectional. The door leaf consists of several sections. When opened, they gather and rise towards the ceiling using a spring point. They save space and create a good seal.

- Recoil. They open to the sides like a wardrobe.

- Roller shutters. Similar to the sectional version, but the gate itself is divided into many parts, which are assembled together and rise upward. Most often, the mechanism is located inside the gate itself.

We must not forget that the gates are created so that the car can enter and exit the garage without difficulty. It is best to treat the gate with silicate paint, which protects the room from moisture penetration and also preserves the material from corrosion.

Mesh fencing

DIY Christmas decorations for the Christmas tree: what you can do for the New Year

A separate idea for your own industrial mini-workshop could be the production of chain-link. The purchase of equipment for these purposes will not exceed 55,000 rubles, and the sales market for such products is quite extensive. You can offer rolls of fencing to owners of household goods retail outlets or wholesalers. In addition, you can sell your goods directly by placing advertisements online and in print, as well as by notifying the management of gardening cooperatives about your services.

By purchasing special equipment, you can start producing chain-link mesh

According to experts, purchasing special equipment for processing waste from making mesh into nails will be a good idea to complement your main production in the garage. Business ideas of this kind will always be needed, because every entrepreneur dreams of getting some kind of insurance for an undertaking in case of temporary downtime. The main thing is to approach the whole process creatively, without forgetting to carefully weigh your own resources.

How to keep your garage tidy?

Cleaning up your garage once is not enough. Over time, frequently used items will begin to clutter the room, reducing the size of the interior space. As a result, this will lead to the fact that the necessary parts will become difficult to find, and the time to complete repair work will increase significantly.

To maintain order in the garage, it is recommended to adhere to the following tips during the arrangement stage:

- place frequently used items in a visible and easily accessible place;

- develop a plan for the arrangement of items for yourself;

- place tools on open shelves;

- designate a separate area for storing large items;

- use all available free space, including ceiling space.

There are a lot of options for arranging a garage. When organizing the internal space, you must first draw up a diagram of the arrangement of objects indicating the sizes of the latter and select cabinets, drawers and other structures according to your own preferences and needs.

Software

Of course, an experienced craftsman can develop a project in paper version, however, to make work easier and save time, it is still recommended to use specialized software that allows you to make a list of all elements of the product, generate drawings of individual parts and obtain a three-dimensional image of the furniture for demonstration to the client. Such programs include:

- "Pro100";

- "Bazis-Furniture Maker";

- "Woody"

- "Astra Furniture Designer";

- "AutoCAD";

- "bCAD Furniture".

To compile cutting maps for sheet materials of chipboard, fiberboard and MDF, separate programs are used that allow you to place parts on the sheet in the optimal order in order to minimize waste: “Cutting”, “MASTER” or “Astra Cutting”.

Organizing a storage system in the garage

Shelving

Racks are the best helpers for putting things in order in the garage. On sale you can find ready-made metal or plastic structures on which it is convenient to place tools, car accessories, garden paraphernalia, etc.

When choosing shelving for your garage, first of all pay attention to their size and the distance between the shelves. It is much more convenient to use designs in which you can adjust the height of the shelves, because

in this case, you can store even large items on them.

Storage systems for garages

Shelving in the garage photo

It is recommended to place shelving around the perimeter of the walls. Thus, they will take up minimal space and bring maximum benefit.

Storing your bike and other things in the garage

Setting up a garage for motorcycles and bicycles

How to clean up your garage

Metal shelving for garage photo

Shelves

Shelves in the garage will be a great alternative to shelving, especially considering the fact that you can make them yourself. But before making and hanging shelves, check the strength of the walls. If the walls in the garage are uneven, it makes sense to pre-plaster them with a durable solution. When choosing the height of the shelves, remember that you will not be able to use them comfortably if they are located above chin level. To save space, you can place several shelves almost under the ceiling, but they are useful only for storing the most rarely used items.

Hanging metal shelves in the garage

DIY wooden shelves in the garage photo

If you store a lot of tools in the garage, purchase or make shelves with special holes in which you can place various screwdrivers, hammer drills, small garden tools, etc. This simple product will allow you to systematize the storage of the most necessary tools, so you will no longer waste time looking for them.

Storing garden tools in the garage

Arrangement of the garage inside with your own hands

Wooden shelves for garage photo

Alternatively, you can decorate your garage using closed shelves created from old wall cabinets.

Hanging cabinets with shelves for garage

Beautiful arrangement of a garage photo

How to arrange the inside of a garage with your own hands photo

Tool boards and perforated plates

Perforated plates, equipped with holders of different lengths, will be useful to those car owners who store many different attributes in the garage. On such a slab you can place gardening tools, a stepladder, helmets, sports equipment and any other things that you use regularly.

Garage arrangement inside photo

How to store equipment in the garage

Storing garden tools in the garage

You can supplement the slabs with various hooks that will serve as holders for ropes or hoses, pull-out shelves for storing a change of clothes, etc.

Photos of garages inside

DIY garage ideas photo

Organization of order and storage in the garage

If necessary, durable brackets can be attached to perforated plates, which will ensure secure storage of wheels and bicycles in the garage.

Storage of bicycles, sports and travel equipment in the garage

How to store a bike in a garage

How to hang a bike in the garage

Garage furniture

Many people refuse to use furniture in the garage, believing that it will take up all the free space without bringing any visible benefit. This statement is true only in relation to old large-sized furniture, which migrated to the garage as unnecessary. Modern metal garage furniture is both multifunctional and compact. As a rule, the furniture for this room is a set of cabinets and chests of drawers, but if you want to create a garage and a workshop, it makes sense to complement the furniture set with a comfortable worktop.

How to arrange the inside of a garage with your own hands photo

Tool storage furniture in the garage with chalk signatures

Creative ideas for arranging a garage

The furniture corner is best located in the farthest corner of the garage. For convenience, equip your workplace with hanging shelves, racks and drawers in which tools will be located.

Furniture for garage and workshop

Workshop in the garage photo

Garage furniture

Basement

If your garage is equipped with a basement, then equip it with the same racks and shelves before filling it with conservation items, old car tires, unnecessary tools, etc. Although these products will take up extra space, they will help you organize your stored items, which will ultimately save space.

Neat arrangement of the garage

Making hanging shelves

Hanging wall shelves

There are two types of hanging shelves - wall and ceiling. Wall shelves can be made in open or closed design, sometimes they have a back wall. They are attached to the garage wall using corners or anchors. These shelves can also be either stationary or collapsible.

Ceiling shelves are placed at the highest level and are attached directly to the ceiling. They can be hung on hooks welded to metal ceiling beams. In addition, eye bolts or special long studs are used as fastenings.

Suspended ceiling shelves

The advantages of such shelves include the relative simplicity and speed of assembly. However, they are quite flimsy and cannot support too much weight. On the other hand, no one will place items that are too heavy to be stored at this level for safety reasons.

The manufacture of the frame for such structures, as well as the shelves themselves, repeats the procedures described earlier in the production of wooden shelves with a metal frame. In this case, fastenings are made in the upper part of the frame for connection with hooks or studs installed in the ceiling.

VIDEO: Wooden hanging shelves

Shelves in the garage: order comes first. General design issues, simple options, step-by-step instructions for making your own (75+ Photos & Videos) + Reviews

Accommodation

There are as many options for garage placement as there are owners of these garages. Below are examples of successful solutions. The desktop will take up useful space; you can’t do without it. It is convenient to place it at the far end wall. It will require approximately 0.6 m in depth and a minimum of 1.0 m in width. To sit in front of the desk, a person needs another 0.6 m. Shelves, racks, etc. can be placed on both sides of the desk. and increase the width of the working part of the table to the entire width of the end wall. After all, you need to place a vice, sandpaper, and drilling machine there.

PHOTO: YouTube.comDesktop at the end wallPHOTO: YouTube.comDesktop option

If the garage turns out to be shorter and the car is longer, then the table can be made folding. A sheet of chipboard 25-35 mm thick is hung on hinges to the garage wall and retractable supports are attached.

Various types of shelves and holders are placed on the side walls of the garage. Here there is a huge scope for the manifestation of imagination and design ingenuity.

PHOTO: chastnyjdom.ruShelves and hooks on the walls

When loading the side surfaces of the garage, you must adhere to the principle of functional zoning. Its essence is that things of the same purpose are located in a group in one place.

In the area of the table, right on the end wall, you can place an operational tool:

- spanners;

- screwdrivers;

- pliers;

- wire cutters;

- drill.

All this is required often, it should be in sight and at hand. One of the options for placing tools is made in the form of a “book”, the pages of which are perforated boards. You can insert a hook into any place on such a board and hang the tool.

PHOTO: YouTube.com “Book” made of perforated boards

Wheels that are stored in the garage can be hung on hooks on the side wall, or they can be placed on a shelf that is slightly higher than human height. Such a shelf will not interfere with the passage between the car and the wall. If the wheels are difficult to lift, you should consider using a simple winch. You can lift the wheels individually, or you can lower and raise the entire loaded shelf at once.

PHOTO: 2drive.ru Wheel storage on a high shelf

All kinds of chemical materials and paints should be kept away from the machine. And if something suddenly turns over and falls, it won’t be on the car. Any small metal items such as drills, bits, small knives can be stored on magnetic tape.

PHOTO: YouTube.comBits and drills on a magnetic strip

Bicycles can be stored in the garage.

PHOTO: YouTube.comBike placement

Related article:

Garage "economy"

The Khamovniki Foundation for Social Research financed the Garage Economy project, which began in January 2015 and will end in March 2016. Its participants visited 9 Russian cities. The observation results indicate that business ideas for production in a garage have not lost their relevance in the era of IT technologies. If you group observations, you get a whole list of garage crafts:

- auto repair shops of all kinds: repair, tuning, painting, installation of additional equipment;

- warehouses for various types of storage, including refrigerators; goods for online trading;

- small retail outlets, the assortment of which is often formed from locally produced products;

- small craft workshops where craftsmen are busy repairing: watches, locks, making keys, stamps and seals, household appliances;

- production of all kinds: metalworking, wood, furniture, advertising products;

- assembly of machine tools and individual elements of technical devices, both independently and outsourced to large enterprises;

- obtaining and processing of agricultural products: from forcing onions to raising poultry and pigs, including processing to the finished product.

From travel notes. “Garage-industrial paradise,” according to observers, is located in Togliatti. In the 5-6 storey GSK, built in the 90s, tens of thousands of people are engaged in production. Counterfeit spare parts for Zhiguli cars are mainly produced on CNC machines. Naberezhnye Chelny looks no weaker. About a thousand heated boxes, two thirds of which are used for the production of parts that are supplied to the plant, are used for restoration and sale.

Electric lighting

Lighting is an important part of the interior design of the garage, without which work at late hours is impossible. The ideal option would be natural light, so you need to think about the design of windows in the work area

For electric lighting, the minimum required is:

- switchboard;

- Lightning equipment;

- sockets;

- grounding

The assembly of all the listed elements must occur according to a pre-prepared scheme. The locations of switches and sockets must be thought out so that their use does not require additional equipment.

The placement of lighting fixtures should be based on the principle of division into functional zones. Based on this, the number of lamps, as well as their location, is calculated.

Electrical diagram for connecting the meter and consumers.

When choosing lighting devices, it is necessary to take into account the level of moisture, and therefore you should choose sealed ones, or insulate the contacts yourself. With good ventilation in the room, the owner can choose a spectrum lamp from a larger list of offers.

It is advisable to hide the wiring under the walls and cover it with grooves, in grooves specially created for this purpose. It is better to entrust electrification work to a professional to avoid future problems with short circuits and possible fires.

Racks and shelves in the arrangement of the garage

Often, among the multitude of suitcases, mezzanines, and bicycles, there is not even a place to park a car, let alone sit in a pleasant, friendly male company in the evening. Therefore, important details in the arrangement of a garage are not only the floor and walls, but also racks and hanging shelves for storing tools, household items and auto parts.

A frame metal shelving unit located along the wall (and if the space of the room allows, you can install a U-shaped shelving unit for three walls), like a faithful friend, will help separate the essential from the unimportant. But first of all, you should conduct an audit of the accumulated things and only then make accurate measurements of the width, length and depth of the structure.

The depth of standard structures in a hardware store is usually up to 1 meter, but this is often not enough, so many car enthusiasts prefer custom-made shelving. In this case, the depth must be determined based on the size of the largest item that will stand on the shelf of the rack. This could be a large suitcase, tires, etc. To prevent a lot of dirt, dust and moisture from accumulating, it is better to drill small holes in the shelves. So, the tools do not rust or gather dust.

By leaving a distance of about 30 centimeters between the floor and the bottom shelf of the rack, you will greatly simplify wet cleaning of the garage, which will now not take much time.

When assembling a frame rack, it is better to use a metal corner (30 by 30 mm) with bolted connections or a profiled pipe. Of course, you can also use welding, but this is not always profitable or convenient. Aluminum profiles are also not suitable for drywall due to their insufficient strength.

An excellent material for shelves is moisture-resistant plywood. It does not absorb moisture, is strong and durable. For enhanced protection, the plywood can be sealed with varnish. You should not make the shelves too long, as the plywood may bend.

Of course, racks and shelves can be purchased at any specialized store, but such a purchase will cost you a lot.

Floor finishing

The floor in garages is precisely the surface that is always in use. Therefore, it must constantly withstand heavy loads from the car and heavy objects accidentally dropped from the hands. At the same time, not a single chip or crack should form on the floor. Requirements for fire and moisture resistance, of course, come first. Typically, a modern garage floor is multi-layered.

A self-leveling mass of sand-based concrete with reinforced mesh in the top layer and waterproofing is a practical and most commonly used option for garage floors.

Stronger, but a little more expensive than concrete, are paving slabs on a dense sand-gravel bed or road paving stones. For additional moisture resistance of paving stones, impregnants (special impregnations that have a water-repellent effect) are used.

An alternative to concrete mixtures is elastic polyurethane, epoxy or acrylic resins. Impact-resistant floor tiles laid out with black and white checkers will look very stylish.

To prevent slipping, the tiles should be slightly rough. It is better not to buy tiles with any pattern, as over time it will become very worn out and will not look aesthetically pleasing at all.

General design issues

Rack with shelves

First of all, you should forget about the first ideas that come to mind - creating the simplest hanging shelves, with a load or area that can accommodate all the property currently contained in the garage. Firstly, this is not rational from the point of view of their manufacture, and secondly, over time, the volume of things stored in the garage increases, so new and new designs will have to be made.

Therefore, it is immediately necessary to plan the design of the shelves in such a way that it is:

- universal

- expandable

- as easily movable as possible

That is, it is advisable not to make each shelf separately, but to make an entire rack consisting of several shelves as a single structure.

Rack with cabinet

The next important question is what the design of the rack will be - collapsible or not. Typically, non-removable structures are more durable and can withstand heavy loads, however, their disadvantages include difficulties in expansion, dismantling and transportation.

Collapsible structures are less stable, their rigidity is far from that of non-collapsible ones. Often, for additional stability, such structures have to be attached to walls. However, they have two special advantages - easy expandability and mobility. In addition, thanks to their modularity, shelving can be made in a variety of sizes.

In this case, the choice depends solely on the desires of each person.

Location and equipment of the work area in the workshop

The dimensions of my garage are 6.5 x 3.0 m2. If you place the machine close to the gate, then with a machine length of about 5 m, approximately 1.5 m remains in the rear. In this place I located the so-called working area. There I made a workbench rack that spanned the entire width of the garage. On it I installed a drilling machine, a vice and concentrated bedside tables with drawers for storing tools, fasteners and auxiliary equipment. I made the floor in this part of the garage from a floorboard; it is comfortable to work on even in winter. There you can do some work without driving the car out the gate.

In order for the car to be placed as close as possible to the garage door, it is necessary that the door in the gate wings be located as close as possible to the wall so that it is possible to enter and exit the garage without moving the car. Another little tip: the switch to turn off the electricity in the garage should be located next to the door. This will allow you to turn off the electricity just before closing the garage, so as not to leave it in the dark.

Basement equipment in the garage

Under the main room of my garage there was a basement bunker 2 m high. I divided it into two zones - food and technical.

He built a brick wall between them. The grocery room is located under the “working room” and is insulated from above (a layer of mineral insulation is laid between the floor slabs and the wooden floor). There you can store cans of preserves, potatoes, apples, etc. The technical area is located under the place where the machine is parked and has access to the main room along its entire length, about a meter wide. This part of the basement is convenient for car repairs, and I also store building materials that are not afraid of moisture there.

The basement is illuminated by 36 volt electric bulbs. For this, a transformer is used, which is located in the main room of the garage next to the electrical panel.

What furniture is needed?

You can equip a garage with different furniture - it all depends on the tasks assigned to this room. The easiest way is to buy ready-made products , but craftsmen can make everything themselves. The main thing is that the furniture meets the requirements listed above and copes with its key tasks efficiently.

All furniture that is usually used in garages can be divided into two groups:

- racks, shelves, cabinets and bedside tables - everything that is used for storage;

- workbenches and tables are work surfaces necessary for carrying out some work.

In addition, if space allows and there is a need for it, you can put a sofa in the garage for relaxing after hard working hours. However, a sofa and other types of upholstered furniture are rather an unconventional solution for a garage, so we will not consider them in the article. In addition, few people choose a sofa specifically for the garage. If it ends up there, it’s obviously after many years of use in the apartment.

Step-by-step guide to building a garage

Let's start building our own cinder block garage.

The first stage is the foundation

Schematic diagram of a shallow foundation

We start with arranging the foundation. A cinder block structure will have a relatively light weight. A shallow strip base is quite enough.

We dig a trench in accordance with the markings. Ideally, the depth of the structure should exceed the freezing level of the soil. Most often they are buried by 60-80, and sometimes by 100 cm. At the same stage, we prepare recesses for the cellar and inspection hole, if their presence is provided for by the project.

Soil freezing level

We attach plastic film or roofing felt to the walls of the pit for waterproofing.

We fill the bottom of the trench with a 20-30 cm layer of a mixture of crushed stone and gravel, followed by careful compaction.

We install the formwork so that the height of the finished concrete structure is approximately 100 mm higher than the ground level.

Let the concrete mixture harden. According to the regulations, concrete gains strength within 28 days. We lay roofing material on top of the frozen tape in two layers for waterproofing.

Trench for a foundation for a garageFormwork with reinforcementFillingStrip foundation for a garage

Stage two - walls

Scheme for laying cinder blocks

Determine the height and length of the walls individually. Laying blocks is done like bricks. The most popular methods are the following:

- half a stone;

- into stone;

- one and a half stones;

- two stones.

The thickness of the masonry directly affects the resistance of the finished walls to wind loads, temperature changes, etc.

Sequence of laying cinder blocks

Most often, as noted, builders use the “brick” masonry method, in which the next laid row overlaps the seams of the underlying one. First we lay out the corners, then we stretch ropes between them to make the masonry even and continue working.

In the process of arranging walls, we adhere to the following important rules:

we lay the blocks with bandaging of the seams; if walls are built without further insulation or other cladding, we carefully control the quality of the seams at each stage. It is recommended to do jointing; We measure each block with a building level

We pay special attention to the starting row; Before laying out the blocks on the side of the gate, we install at least their frame for better orientation. We do this by checking the level and temporarily fixing the structure with spacers; maintain a slope to the front of at least 0.3 m.

In the upper part of the walls we leave nests for installing floor beams. Recommended dimensions – 200x200x150 mm. You can then fill in or blow out the gaps. The optimal step for placing nests is 100 cm.

The beams are located at the same distance and filling elements are laid on them, which perform the enclosing function. Ceilings. Ceilings and sheathing. Garage ventilation scheme. Installation of ventilation.

Third stage - roof

We make the base of the roof from I-beams - this is the best option. We select the length of the elements so that it exceeds the width of the building by 250 mm.

Garage roof diagramGarage roof

We lay the beams across in increments of about 1 m. We fasten the beams in a suitable way, for example, using anchors.

After this, we sew up the base with beams 4 cm thick. We lay the beam as tightly as possible. We put roofing felt on top of the beams, insulation on it (mineral wool, slag or expanded clay), fill in 2 cm of screed and finish the “pie” with aquazol, rubemast or other suitable material. If you wish, you can choose a different finishing coating at your discretion.

Laying roofing felt on the sheathing Laying insulation Laying reinforcement Concreting the floor Concreting the floor Bicrost flooring is done using a torch Waterproofing a flat roof

Stage four - floor

We make the floor level with the plinth. As a standard, a screed with a thickness of at least 100 mm is poured. We first clean the surface of debris, level it and, if necessary, fill the bottom with sand or fine gravel.

Diagram of a floor in a garagePouring floors in a garageHow to make a concrete floor in a garageHow to make a concrete floor in a garageHow to pour a floor in a garage with your own handsConcrete floor in a garage

We make the screed from concrete grade M200. We pour the material continuously, slowly, in several layers. Let the concrete set and rub the surface.

To make it convenient to enter the garage, we are installing a ramp in the front part of the building. Be sure to make a 50-70 cm blind area around the entire perimeter of the building. It will ensure timely drainage of water from the base.

An option for making a floor in a garage from concrete and blocks. We lay out concrete slabs, and fill the space between them with concrete and rubble stone. We lay out concrete slabs, and fill the space between them with concrete and rubble stone.

Example of making a screed

All clayey soils (including clay, loam and sandy loam) with a high groundwater level are called heaving soils. Clay in heaving soils retains moisture well, and when the soil freezes, it expands in all directions, which can lead to the rise of buildings located on it.

For shallow construction work, the fight against soil heaving involves removing part of the soil under the building and replacing it with materials that do not retain moisture. Additionally, measures are taken to prevent soil freezing near the building; For this purpose, the soil is insulated, for example, with expanded polystyrene.

Expanded polystyrene as insulation shifts the temperature isotherm closer to the surface, i.e. prevents the soil from freezing, which does not lead to its rise.

How to fill a garage entrance? How to concrete correctly? Stages of work on arranging and concreting the screed:

- Remove the soil to a depth of approximately 40 cm according to the size of the future screed.

- Lay the first layer of sand (sand cushion), compact it tightly, and pour water on it.

- Place a second layer of sand, compact it, and pour water on it.

- Lay a layer of fine crushed stone to the top of the dug pit.

- If the screed is not arranged for the entire length of the car, the remaining distance can be covered with a layer of crushed stone, after first removing the vegetation in the backfill area and laying geotextiles (so that the crushed stone does not sink into the ground).

- Separate the future screed from the foundation using a strip of linochrome if you do not plan to tie the screed to the garage foundation. Leave a gap of approximately 3 cm between the tie and the gate frame.

- Make formwork for their boards on three sides. The formwork can be made from boards with a thickness of 25 mm. Carefully secure the formwork (you can sprinkle it with crushed stone on the outside over the entire area of the boards), leveling it exactly horizontally. The boards can be lubricated with special formwork oil to make it easier to separate them from the concrete without damaging the screed. Hormusend HLV-37 lubricant is well suited for these purposes.

- Place insulation (extruded polystyrene foam slabs 5 cm thick) over the entire area on the crushed stone cushion.

- Tie a frame made of reinforcement for pouring mortar with crushed stone.

- To prepare the solution, you can add “Fairy” as a plasticizer.

- Pour the base concrete layer using a vibratory compactor.

- After laying the main concrete layer, place a mesh with a 50x50 mm cell (reinforcement) on it.

- Mix the solution, without adding crushed stone this time (only plasticizer, cement, sand), pour in the finishing screed.

- Level the finishing screed using a board.

- Iron the screed after a sufficient amount of moisture appears on the surface of the screed.

- Immediately cover the resulting screed to protect it from birds and animals while drying.

The concrete screed will gain hollow strength in about 15 days. The screed must be watered for 5 - 7 days so that it remains constantly moist. You can also cover the screed with film, and if sufficient moisture in the screed is maintained, it does not need to be watered.

In the future, it is necessary to make a drainage drain near the screed so that the ground underneath remains dry.

- cement grade M400;

- sand, layer thickness: 15 cm each;

- crushed stone, layer thickness: 10 cm;

- concrete, layer thickness: 15 cm;

- mortar proportions for basic concreting: sand – 3, cement – 1, crushed stone – 5;

- mortar proportions for finishing screed: sand – 4, cement – 1.

“Fairy” as a plasticizer makes the solution more elastic (due to the addition of glycerin). Ratio: 1/3 cup of plasticizer per 1/4 cubic meter of solution.

Iron plating increases the protective properties of concrete and increases its waterproofing characteristics. Technology - dry cement is poured onto the screed (wet).

And here is a video on how to make a blind area for a garage.

The garage entrance device allows you to create a convenient and clearly visible area and allows the car owner to confidently and accurately guide his car. Water accumulating at the threshold also does not penetrate inside the garage if a properly constructed entry device is installed in front of it.

The effort spent on arranging the garage is more than repaid by the convenience and good mood of the car owner from its easy and safe operation.