The furniture manufacturing industry provides a huge number of different kitchen furniture to choose from. Sometimes a dishwasher is offered separately and is installed by the buyer independently. This does not require any special knowledge or skills.

If the sink is purchased separately and requires installation, it is advisable to entrust this work to professionals.

To make a hole correctly, you need the simplest tool. The question of how to cut a countertop for a sink is not very difficult. However, if you do not follow certain installation requirements, the installed equipment can be damaged.

The sequence and manipulations performed are similar to cutting a hole in chipboard.

To make a hole correctly, you need the simplest tool.

The location for the cutout is selected taking into account the minimum distance for draining water into the sewer and connecting the water supply.

It is better to do this outdoors, as there will be a lot of dust during the sawing process.

The sink can be installed relative to the level of the working surface in the following ways.

- Below the table top. This arrangement looks very impressive, but will additionally require the use of a special tool. The sink itself must have a certain shape. In this case, it is attached from below using special fasteners. They are usually sold as a set. The open end must be impregnated with a water-repellent agent. At the same time, it must have sufficient thickness.

- On the same level. In this situation, it is very important to correctly make the required recess equal to the thickness of the side. It should be perfect around the entire perimeter of the sink being installed.

- Above tabletop level. For this type of installation you need the simplest tool. No special effort is required for this installation.

You will need to wear protective gloves on your hands, and protect your face with a special transparent mask.

Sometimes a dishwasher is offered separately and is installed by the buyer independently.

Support the workpiece from the reverse side

Regardless of the type of drill bit, when metal penetrates wood, the unsupported wood fibers on the back of the workpiece are torn, resulting in chips. Therefore, you should not forget to support the back side of the material with a trim

boards. The backing scrap supports the fibers where the drill exits and prevents a sharp increase in feed at the end. When making holes on a drilling machine, simply place the scrap under the workpiece, and when using an electric drill, secure it with clamps. If at the beginning of drilling the fibers around the hole rise or small chips form, apply masking tape to the surface, and then mark the center and start drilling.

How to cut a circle with a hand jigsaw

A hand jigsaw for cutting in a circle is of limited use, since the holding frame does not allow the jigsaw to be moved relative to the workpiece. If you start cutting from the edge of the workpiece, you will only be able to cut a few cm before the holding frame rests on the edge of the workpiece. Therefore, they cut with a hand jigsaw without moving the tool along the workpiece, but vice versa. The jigsaw file remains almost in place, and the workpiece is moved towards it. Example in the picture:

Installing a sink in a structure made of other materials

Installing a sink in a countertop made of wood or chipboard is not difficult if you have the required tools and basic handling skills. A countertop made of artificial or natural stone installed in the food preparation area will be more durable. It will look more solid, but it will be more difficult to install a sink into it yourself.

The use of sealant not only prevents unwanted water penetration

When purchasing kitchen furniture with such a surface, it is advisable to have a ready-made product that will only require connection to the water supply and sewerage system.

Sealants containing alcohol are more often used for wood and plastic.

If the sink is purchased separately and requires installation, it is advisable to entrust this work to professionals. In a stone processing workshop, craftsmen will perform the required work without damaging the surface. To do this, they have the appropriate skills and have the entire set of necessary tools.

There is a different sealant for different surfaces.

If you decide to cut a hole in the countertop for the sink yourself, you will need a special tool - a grinder with a diamond wheel. Great care is required when working with this tool. You will need to wear protective gloves on your hands, and protect your face with a special transparent mask.

The sealant is used to prevent moisture from entering the areas of contact between the sink and the countertop.

It is better to do this outdoors, as there will be a lot of dust during the sawing process. The sequence and manipulations performed are similar to cutting a hole in chipboard.

The location for the cutout is selected taking into account the minimum distance for draining water into the sewer and connecting the water supply.

Professional advice on installing sinks: what to look for

Experienced installers share the following secrets of their work:

- When installing a mortise sink yourself, you need to check the dimensions of the hole several times. It should not be too large, otherwise the sink will “walk” in the groove and the fastenings will not provide the required strength.

- When installing a stainless steel sink, do not overtighten the screws. This may cause damage.

- Instead of the seals that come with the sink, you can use sealant. You shouldn't save it. It’s easier to carefully remove excess than to deal with leaks later.

- When using a screwdriver, it is important to be careful not to bend the hardware. If you don’t have much experience with this tool, you should give preference to a Phillips screwdriver.

Silicone sealant should be checked for hardening speed before use. Source mtdata.ru

Necessary materials

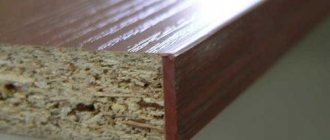

The sealant is used to prevent moisture from entering the areas of contact between the sink and the countertop. Water can greatly damage chipboard. There is a different sealant for different surfaces. When working with artificial stone, only silicone is used. Sealants containing alcohol are more often used for wood and plastic.

If you decide to cut a hole in the countertop for the sink yourself, you will need a special tool - a grinder with a diamond wheel.

Using a sealant not only prevents unwanted water penetration. This also serves as additional strength to the connection.

If the sink is purchased separately and requires installation, it is advisable to entrust this work to professionals.

- electric drill

- electric jigsaw

- wood drill with a diameter of 10 mm.

- set of wrenches

- brush

- adjustable wrench

- rasp

- screwdriver

When purchasing kitchen furniture with such a surface, it is advisable to have a ready-made product that will only require connection to the water supply and sewerage system.

Before cutting a hole in the countertop for the sink, mark the required hole. To do this, a template is made from cardboard or thick paper. Some manufacturers and manufacturers of sinks include a template with the product itself. If you have chosen the option of installing on a tabletop and the sides are of sufficient width, you can mark without a template. For this, the sink is used as a template. The upper surface is applied to the plane and traced along the contour with a marker or pencil. For ease of installation, it is advisable to remove the tabletop. Having stepped back 0.5 - 1 cm from the drawn line, a working contour is drawn along which the cut is made.

It will look more solid, but it will be more difficult to install a sink into it yourself.

Having marked the cut line, the template is removed and you can begin the process of cutting out the place for washing. A drill is used to drill a place for an electric jigsaw file, approximately 10 mm in diameter. For a quadrangular or triangular sink, holes are made in all corners. If the product has a round or oval shape, one will be enough for the job.

Installing a sink in a countertop made of wood or chipboard is not difficult if you have the required tools and basic handling skills.

The hole and cut are made from the side of the laminate, this will prevent it from chipping. Use a jigsaw to carefully cut out the required hole along the drawn contour. The electric jigsaw must be pressed firmly against the surface. The saw blade should go exactly at a right angle.

The sink is covered with a sealing tape supplied with the product.

The inner part being cut must be supported while doing this work. Or position the tabletop so that when cutting is completed, this part does not fall. If the remaining and removable parts are abruptly separated, the laminated coating may crack. Or a part will break off from the chipboard.

You can use a drill with a special drill - a furniture crown, just immediately take a drill of the required diameter.

If there is no room for such an arrangement, or the tabletop has not been removed, use construction tape. Sawing is done in this case with stops. A 10-15 cm cut is made, which is then taped on both sides.

A drain and, if provided for by the design, a mixer (water tap) are mounted to the bowl.

After the cutting is completed, the sink is first tried on. It should fit freely, but the gap should not be large. If it fits too tightly, you should widen the installation site with a rasp or jigsaw.

Having marked the cut line, the template is removed and you can begin the process of cutting out the place for washing.

Now you should carefully “sand” the inner end to which the sink will adjoin. This is done with fine-grit sandpaper. The resulting dust is removed, and a thin layer of sealant is applied to the contact area using a brush.

For ease of installation, it is advisable to remove the tabletop.

Slice processing procedure

Experienced experts advise: since in the process of creating a hole along the inner edge of the cut, roughness and small chips often form, you need to become familiar with the rules for processing the cut, failure to comply with which leads to a number of problems:

- Since it is impossible to ensure absolute sealing of the unprotected surface of the chipboard, its insufficient degree causes moisture to penetrate into this part of the tabletop. As a result, decay processes may be activated and a fungal coating may appear.

- Subsequently, the cutting edge becomes fragile and the stability of the shell decreases, which ends with its distortion.

- As a result of rotting of the countertop, its aesthetic, strength and performance qualities are reduced and then replacement will be required.

To prevent the above-described troubles, you should:

- Treat the end surface of the cut with fine-grained sandpaper and treat it with high-quality plumbing sealant. Professionals recommend using a spatula to perform this work; in the absence of which, the composition can be applied with your finger. Carrying out protective measures helps prevent wetting and subsequent swelling of the surface of the cabinet.

- If, when performing work such as cutting out a sink in a countertop, chips are found on the front side of the plastic, they are carefully treated with sealant, and there is no need to apply it in a thick layer, since in this case the thickness is not important.

- There is another way to protect the end side of the cut - it involves treating it with PVA glue. Despite the laboriousness of this process, it is reliable, like the previous option. To enhance the protection effect, the applied layer of glue should dry for about 30 - 50 minutes.

- Next, you should glue the seal made of foamed polyethylene; it is usually included with the sink. This material is fixed on the side of the sink along its perimeter. When, after attaching the seal, it can be seen, the material is carefully trimmed with a knife. If this is not done, the edges of the sink will not fit tightly to the countertop and water, getting into the gaps created, will cause swelling and further rotting of the end.

Since the process of attaching the seal directly affects the performance and wear resistance of the kitchen set, attention should be paid to it:

- You need to take the material and degrease it with a rag soaked in gasoline and solvent.

- Then sealant is applied to the seal in a continuous thin strip so that the glue does not come out when compressed and pressed against the outer edge of the sink.

How to embed a sink into a countertop with your own hands?

How to properly and easily embed a sink into a countertop? This question is faced by everyone who has started renovating their kitchen. We will tell you clearly and in detail how to do the installation competently and quickly.

How to install a sink into a countertop?

Often, the installation of the sink is carried out by the manufacturer. But it happens that this service is not listed in the price list. Then this concern falls on your shoulders. But don't worry. You can install the sink yourself, armed with the necessary tools and advice from professionals.

Installing a sink involves several stages. At the initial stage, you must make a hole in the middle of the array, then process the edges. The next stage is inserting the sink, fastening its back side and sealing the distance between the countertop canvas and the sink. The final stage is the supply of water supply and sewerage communications.

The key to a high-quality sink installation is: reliable fastenings, sufficient fit and high-quality sealing. Moisture is a fairly aggressive factor affecting the kitchen countertop, especially if it is made of chipboard. High-quality installation will prevent the tabletop from drying out or swelling, which will extend its service life many times over.

Garden sprayer: types, tips on how to choose, DIY assembly

Performing markup

This is quite an important stage. Place the sink in the center of the countertop. Remember that the gap from the edge of the countertop to the side of the sink must exceed 50 mm. If this distance is less than 50 cm, then the sink needs to be deepened.

The distance from the corner plinth should be more than 30 mm so as not to create problems during cleaning. If the dimensions of the countertop allow, then it is better to leave a little space on both sides for household chemicals and a sponge.

If the manufacturer provides a template for inserting the sink, then the task is much simpler. The template is glued to the tabletop and makes marking easier.

If the countertop does not have a template, you should install the sink on it, upside down, and trace along the contours with a washable marker. If there is a sink and a drying compartment or waste tray in one block, then one common hole is cut out.

How to make a hole for a sink?

To make a hole in the tabletop you will need an electric jigsaw. It is suitable for countertops made of wood and chipboard. If the countertop is made of durable materials, then a jigsaw will not cope. First, prepare 4 holes with a diameter of 1 cm in the corners of the rectangle, without crossing the marking line. Then a file with the required tooth length (2 mm) is put on the jigsaw. To avoid chipping on the front surface, choose the opposite direction of the tooth.

Apron for the kitchen (photo): choice of design and material

Holes are made on the left and right, and then the wooden plank is pulled in with self-tapping screws across the sawn lines so that the cut part does not fall prematurely under the force of gravity. The cut out part is carefully removed, and the exposed edges of the hole and irregularities are coated with liquid silicone.

Installation of sink and connection of communications

Here again you will need liquid silicone. Stepping back a couple of millimeters from the edge of the hole, we apply the silicone in a thickness just above the side of the sink. Stepping back from the first one another centimeter, we apply another flagellum.

After half an hour, the silicone will dry and stop sticking to your hands. Then you need to insert the sink into the hole and firmly press the edges so that the silicone strands take the shape of the sink, and leave for a few minutes. Then the sink is removed and the silicone is checked. If it is not broken, then everything is in order, and the sink will have a reliable additional side.

We attach fittings to the countertop to install the mixer and hose. It is more convenient to attach the siphon to an installed sink. Many sinks have special loops for screw clamps in the shape of the claws. They help tighten the sides to the tabletop more tightly.

Painting with hearts using the isothread technique

Tips from the professionals

The most difficult thing is to make the hole correctly. If it turns out to be larger than expected, the paws will not be able to hold the sink. Saw out the hole, just short of the marking, and if the sink doesn’t fit, a rasp will help you adjust the hole to size.

Different silicones harden differently. Before pressing down the edges of the sink, check how long it takes to tighten the drop in minutes. If you rush, the silicone may burst.

Do not tighten the screws too tightly. Otherwise, the sides of the sink will bend upward.

How to embed a sink into a countertop with your own hands? updated: by:

This is interesting: Do-it-yourself supply and exhaust ventilation of a private house - device and diagram

How to do this kind of work yourself

For example, consider installing washing equipment in a countertop made of chipboard. Installation type – above the table surface. The entire work process can be divided into the following stages:

- marking the future hole;

- cutting out a hole;

- sink installation;

- sealing joints.

Work should begin with preparing the necessary tools. Make sure that all necessary hardware is included with your sink. Tools you will need:

- construction pencil;

- level, corner and tape measure;

- drill and bit for woodworking;

- screwdriver;

- electric jigsaw;

- silicone and screws.

You can start working. Make sure that you are not disturbed by foreign objects. It is advisable that the tabletop is not secured to the cabinet frame. If the table is already assembled, it doesn’t matter, you can cut out the hole just like that. We carefully carry out the markings. Let's look at how this is done for a rectangular sink:

- Using a construction pencil, draw two lines perpendicular to each other. At the point where they intersect there will be a drain hole.

- We turn the sink over, lay it on the countertop and outline its outline. At the same time, do not forget to take into account the level of the edge of the sink relative to the table doors.

- We measure the width of the sink side and draw the inner contour. The cutting will be done along this line.

- Let's double-check all the parameters again and start cutting.

You need to cut the hole using an electric jigsaw. To insert a file, you need to drill technological holes in the tabletop. Usually they are performed with a drill at the corners of the contour. All drilling work is performed on the front side of the tabletop. This will make it possible to do the work without any kind of chipping of the laminated areas of the table. Now you can take a jigsaw and cut a hole along the inner contour. After this, you should first try on your sink to the resulting hole.

Note! If there is a slight play, it was cut out correctly. If there is no play, additionally process the edges of the hole with a jigsaw.

Now you need to clean the edges of the hole. This is necessary so that uneven edges do not interfere with high-quality sealing of the joints. This work is performed with fine-grained sandpaper. After cleaning, we perform sealing. There are two ways you can do this:

- Sealant.

- PVA glue.

The first method is good, but it should be done with great care so as not to miss areas of the tabletop. It’s best if you don’t skimp on the sealant and apply it with a decent supply. The second method is more difficult - PVA glue must dry for almost an hour. But it reliably protects against moisture penetration.

Photo instructions

Cut out the template

Aligning the template

Cutting out Using the inner diameter of the template Trying on the sink Assembling the sink Connecting communications

Apply sealant

Install the mixer Instead of sealant, you can use filler

Types of sinks by installation method

Installing a sink with your own hands may involve different technologies. Let's look at the main design types of kitchen sinks.

A countertop kitchen sink can have up to two bowls

Types of kitchen sinks:

- Overhead models. This type is considered the most common due to its ease of installation. Even a beginner can handle installing an overhead sink. They are usually made of stainless steel and are generally rectangular in shape. Installed on top of a kitchen cabinet that does not have a countertop.

- Recessed sinks. Such accessories are installed in a prepared hole in the tabletop, which must be cut exactly to the size of the structure. The sink is immersed in the hole treated with sealant and fixed with fasteners.

- Under-table products. Their installation method is similar to the previous one: the sink is installed in a hole cut in the countertop. The only difference is that not all countertop materials can provide an integrated type of installation, and the cuts of the hole must be processed carefully.

An undercounter or integrated kitchen sink requires a complex type of installation and generally can only be done in a factory setting

One of the important criteria for choosing a sink is its depth. A sink that is too deep (20 cm or more) is not convenient to use, as it forces you to bend over too much. A shallow bowl (up to 15 cm) is bad because water knocking on it from an open tap will splash around the entire working area.

The choice of mixer height depends to a large extent on the depth of the bowl. For example, for a deep sink it is better not to choose a faucet with a high spout, as well as for a shallow one with a low one. This all affects ease of use.

A high faucet over a deep sink is inconvenient because the water pouring out of it will splash heavily around

Of all the types of sinks listed above, today's users mostly choose the mortise type.

Such sinks are affordable, have a comfortable depth and, importantly, a modern appearance

Sealing the joint and installing the sink

Particular attention should be paid to sealing the joint. Otherwise, the water that will fall on the countertop when washing dishes in the future will begin to flow into the gap between the edge of the sink and the table cloth

Because of this, deformation of the wooden elements of the set and their delamination may begin, which should not be allowed under any circumstances, since this process will significantly shorten the service life of the countertop, and in the future it will have to be replaced with a new one.

Sealant treatment

Prices for polyurethane sealant

Polyurethane sealant

You can attach a seal along the cut edge of the hole. All protruding parts of it must be cut off with a knife - it should cover only the end part of the cut. Silicone sealant must be applied on top of it, which will ensure waterproofing of the joint. Only after this can you install the sink itself. You should have time to install it before the sealant hardens.

The sink must be lowered into the cutout and carefully aligned along the very first marking line. After this, you need to fix it on the wrong side using the fasteners supplied with it. The screws on the fastenings should be tightened tightly only after the sink is leveled and installed correctly. Overall, it should fit very tightly once installed.

Installation and installation of the sink

Marking

The sink should be centered in the middle of the depth of the countertop, shifting to the left and right for the most convenient location. The distance from the side of the sink to the edge of the countertop should not be less than 50–70 mm, otherwise the sink should be moved slightly deeper. It is not recommended to make an indentation from the corner plinth less than 30–40 mm, otherwise it will be difficult to wipe the surface in this place. When installing a sink in a corner section, it is useful to leave a space of 100–140 mm from both walls in order to obtain a small space for convenient placement of household chemicals and cleaning accessories.

If there is no template, the sink must be turned over and installed on the countertop, carefully observing the indentations. The sink should be outlined in a circle with a water-soluble marker and removed, and then the contour line should be shifted inward by the width of the side. If the bowl does not follow the external contours, which is the case in sinks with a drying tray, the marking lines must be shifted a certain distance on each side. If two sinks or a waste compartment are combined in one block, a common hole is cut for them.

Installation of an integrated sink

Installation of a sink made of acrylic stone or quartz agglomerate, made according to individual drawings, is carried out under production conditions.

There are 2 types of integrated sinks:

- bottom mounting, with a slight overhang of the countertop over the sink;

Sinks made to order from countertop material are visually very attractive. There are 2 important points to consider. The corners and edges of sinks cannot be rounded, which complicates maintenance. The design of the sink is not monolithic, like factory sinks, but is glued together from segments, which makes it less durable. This type of washing requires careful operation. Increased load should be avoided. The installation of a waste shredder that creates vibration is highly undesirable.

Advantages of installing an undermount sink over an overhead sink

Installation of a sink in the kitchen can be done in an overhead or mortise manner. By giving preference to the first option, in addition to the bowl for washing dishes, you can additionally purchase a pedestal or cabinet on which it is installed. Installation of a mortise sink is carried out directly into the kitchen countertop. The second method is preferred much more often, even though it is an order of magnitude more difficult to implement, but against the backdrop of many advantages, this disadvantage becomes less significant.

First of all, overhead sinks are caused by the constant presence of moisture in the room, which forms between the cabinets that are located near the unit with it. One of the main positive aspects of mortise products is the wider variety of assortments, from which it is much easier to choose a sink, taking into account all personal preferences and needs. They are made from more different materials and some come in shapes that countertop sinks are not made in. Built-in kitchen sinks are made of ceramic, stone, copper, plastic, porcelain stoneware, bronze and stainless steel. Externally, they can have round, rectangular, angular and one of many asymmetrical shapes.

The sink can be installed in 3 ways: exactly at the level of the countertop, slightly below or above it. This depends not only on personal preference, but also on the configuration of the purchased kit, which is why, at the time of purchase, you should find out how the bowl should be placed and what fasteners need to be used during installation

The choice of fasteners also requires special attention, since the level of strength of these components directly affects the period of their operation

Types of sinks and their design features

There are a number of requirements for how to properly install a sink in a countertop. This process must be carried out according to technology. The choice of a specific solution regarding the installation method depends on the design of the sink.

The most popular types are:

- Overhead products

. They are considered the most budget option, which is characterized by the ease of installing the sink into the countertop. This installation principle is based on the fact that the sink is placed on a free-standing cabinet, as a result of which it is a continuation of the countertop. Sinks of this type have disadvantages - insufficient thickness of the product material and the presence of a gap between them and the countertop, which causes inconvenience. Experts recommend choosing an overhead sink when the kitchen set has several separate sections. If they are united by a common countertop, the best option would be to use a built-in model. - Built-in sinks

. These products are installed directly into the countertop. Installation work should begin by preparing a hole in it. The technology of inserting a sink into a countertop involves attaching the structure to the inside of the module using special brackets and clamps. Built-in models of this type are distinguished by their solid appearance and convenient operation. Despite the fact that they are more expensive, specialists with extensive experience prefer them because of their practicality and the ability to prevent moisture from accumulating between the bedside tables. - Undercounter sinks

. The price of these innovative models is so high that it makes them inaccessible to most consumers. The installation principle of such sanitary ware involves fixing them below the level of the countertop and therefore they form a single whole with it. Undermount sinks have an aesthetic appearance and good sound absorption. Thanks to the effective sealing of joints, these products are characterized by hygiene and long service life.

Learn more about installation methods

As we have already said, installing a kitchen sink involves two options:

| Overhead |

The disadvantage is the humidity that invariably forms between the unit with the sink and the adjacent cabinets. |

| Mortise | Installation is much more complicated and it will be very difficult to do it yourself. This method is favored by a variety of shapes and types of sinks. For example, it is possible to install models made of stone, plastic, stainless steel, copper, brass, and round, rectangular, corner, asymmetrical sinks. |

It is possible to embed a sink into a countertop in different ways; in this case, not only your desire plays a role, but also the design capabilities of the set.

Based on this, it is possible relative to the surface:

- flush with it;

- easily above or below it.

Preparation for installation

Installing a sink is the last or final stage of assembling the water use unit in the kitchen.

Based on this, you should prepare for it thoroughly:

- First, be sure to supply water to the installation site.

- Make a sewer drain.

- In addition, you should take care of the tools, where the jigsaw plays the main role. You can purchase it or rent it for a couple of days; at the same time, buy new files for it so as not to experience inconvenience during work.

- In addition, do not forget to purchase silicone transparent sealant, and it is better not to pin your hopes on the self-adhesive foam rubber edging offered in the kit. It is not good because moisture will slowly accumulate in it, which will soon begin to emit an unpleasant odor, instantly destroying the countertop under the overhead sink. We simply recommend not to use it at work.

- When purchasing a kitchen sink, determine whether it comes with a template or stencil that will help you cut it into the countertop. In most cases, it comes as a package, so don’t rush to tear it apart, look to see if there is a pattern on the cardboard. If not, then we will tell you below how to mark a place on the surface by applying a sink to it.

- The siphon, supply and drainage pipes are not included in the sink kit or are very rare, so do not forget to buy them additionally.

Making space for an overhead sink

There is no difference what configuration the sink will be, the instructions will be exactly the same:

- Before cutting out a sink in the countertop, choose a place for it. In addition, make sure that:

- there was a free approach to it by water and sewer pipes;

- there was a distance of at least 60 mm from the edge, otherwise the narrow layer could be broken;

- The supporting structures of the cabinet were not located under the tabletop; they cannot be cut during work, otherwise the reliability of the set will decrease.

- Make a template on thick cardboard or use a ready-made one placed on the product packaging. The second option is to turn the sink over and use a marker to trace an outline along the countertop. Then step back 10 mm inward and make a copy of the contour along which you need to cut.

- Cut out the space for the sink along the outlined contour. At the same time, don’t worry if there are chips on the tabletop where the drink was.

Take an electric drill with an O 10 mm drill and drill a hole in the tabletop at the inner mark to insert a jigsaw file into it. After this, take your time and carefully cut along the line.

- Process the resulting cut. First clean it of dust and fill it with silicone so that it does not absorb moisture.

Installing a sink in a cabinet

- Put on the fasteners, but do not fix them at all, so that you can tighten them over time.

- Install the faucet on the sink, if provided.

- Coat the inside of the sink with silicone sealant and install it on the countertop.

- Moving the structure, find out the appropriate position for it and tighten the fasteners completely.

- Remove any fresh sealant that has protruded around the perimeter, and until it has hardened, do not use the structure. Use it also to process possible gaps.

Making and using a template

Ready-made template for washing

The process of installing a sink into a countertop consists of several stages. To properly perform this labor-intensive job, you need to carefully cut a hole in the tabletop, and it is advisable to follow the instructions below.

- First you need to purchase a blank sheet of cardboard of the required size from which the template will be cut. This work step will be simplified if the manufacturer, which often happens, made the template himself and included it in the product packaging. All that remains is to cut out the template using scissors along the drawn contour. If there is no template, you need to take the sink, turn it upside down, attach it to the cardboard, then use a pencil to draw the necessary outline and cut out the template along the finished outline. If there is no packaging with a pattern, and there is no necessary sheet of cardboard, the inverted sanitary ware is drawn directly on the tabletop.

- Next, you need to evaluate the future location of the furniture block. You need to know in advance where the mixer will be installed, how to route the pipes, and whether the countertop will be trimmed before final installation. It is also necessary to examine the structure of the furniture from the inside. This will allow you to determine which elements, if necessary, can still be trimmed, and which cannot be touched - the load-bearing fragments of the tabletop must remain intact and untouched.

Need to indent

- Once the template is ready, it's time to use it. To mark the tabletop, you need to attach a template to its surface, and it must be motionless. After this operation, a contour is drawn. The same work is carried out if a factory template is available. You can cut right away along the outlined line. If cardboard is used or the upside down sink was traced with a pencil on the countertop, there is additional work to be done. The fact is that the drawn line will follow the edges of the sink, and its bowl will be inserted into the future hole. Therefore, you need to draw one more contour - the internal one. When drawing it, you need to take into account the distances from the edge of the sink to the fastening elements of the plumbing fixture. The result is a new template that is tailored to the dimensions of the bowl. It is applied to the surface of the tabletop and a new contour is applied along which a hole can be cut.

- There is an option in which a cardboard template is attached to the surface of the tabletop and a hole is sawed along its edges. If you look at such work from the practical side - it is inconvenient - it is better to draw the outline with a pencil. When cutting along a drawn line, there is a real chance of chipping on the inside edges of the tabletop. To avoid defects, it is recommended to stick masking tape to the surface in the area of the intended contour, which can be easily removed in the future. In order to start sawing, you need to make a hole in the body of the tabletop with a drill from the inside of the drawn line. A jigsaw file is pulled into the drilled hole, after which it is fixed in the tool. You need to cut carefully and without haste, since when pressed, the blade may move away from the intended contour.

- The resulting cut is cleaned with sandpaper, blown and thoroughly lubricated with silicone. Thanks to this composition, the harmful effects of moisture on the cut surface will be minimized. If any fragments of the furniture block interfere with the installation of the sink bowl, they must be carefully trimmed. Measurements for trimming must be taken accurately - it is not recommended to do such work “by eye”. You need to know that when using a template from the manufacturer, cutting out internal elements is much easier and simpler, since such nuances are also provided for in its manufacture.

Features of assembling different types of kitchen sinks

So, the question of how to attach a sink to a cabinet in the kitchen has been resolved. Before you start working, you need to assemble the cabinet itself. As a rule, in such structures the opening at the back is open (this is done for the entry of water and sewer pipes), sliding or hinged doors are installed at the front, and the top cover may be absent or have a hole for insertion.

It is worth remembering that assembling the sink cabinet must be done with special care and attention. Firstly, due to a weakened tabletop (or lack thereof), all connections are subject to a large load

Therefore, it is worth tightening the fasteners properly and do not forget to install special tie-down structures inside the cabinet after completing the connection.

Secondly, no matter how well the plumbing is done, water leakage cannot be ruled out

Therefore, it is very important to prepare the furniture for this. A rubber seal must be glued along the lower edge of the sidewalls

For greater durability, it is advisable to treat wooden parts with compounds that repel water.

Installation of mortise sinks

You should start installing a kitchen sink using the mortise method by assembling the cabinet and checking its stability in place. No vibrations are allowed: when assembled, the structure must stand absolutely still. Correcting errors after installing the sink in place will be much more difficult.

To mark the location of the bowl on the countertop, you need to place a mounting template. It comes with the sink (usually as part of the packaging). With its help it is easy to mark the contours of the hole.

At this stage, it is extremely important to accurately take all measurements. Having determined the location, attach the template with adhesive tape and draw one thin line with a pencil along the contour of the future hole.

The easiest way to make a hole is with a power tool. First, several holes are drilled with a drill, then a jigsaw blade is inserted into the resulting channel and a cut is made. There is no need to rush when working: the neater the edges at the landing window are, the easier the sink will fall into place.

Kitchen sink sealant is applied along the edge of the installation window. All that remains is to seat the bowl in the cut and wait the specified time for the composition to set. After this, the cabinet is put in place and communications are connected.

Installation of overhead sinks

There are two ways to solve the issue of how to install a sink in the kitchen:

- For sealant. This mount is unreliable and can only be recommended for the lightest models.

- On L-shaped mounting plates. You will need 4 of these elements. They can come complete with a cabinet or sink. If not, you will have to buy them at a hardware store. In this case, the plates are a reinforcing element, but a sealant will also be needed.

Four plates are attached to the top edge of the cabinet. The wood is coated with sealant and the sink is placed on the fasteners until it is completely seated. The upper part of the corner is placed under the edge of the sink. If a little sealant squeezes out when tightening the fasteners, it should be wiped off with a rag.

There are also variants of sinks in which holes for self-tapping screws are made in advance.

How to securely attach a sink to a cabinet and countertop

For reliable fastening, you can use some tricks:

- To ensure that the teeth of the mortise sink are securely attached to the wood, you can sharpen them with a file;

- if the cabinet has defects, you can use wooden blocks for correction;

- In order for the sealant to form a reliable layer that cuts off water and holds the sink bowl in place, you need to thoroughly clean the cut and the surface of the cabinet from sawdust, dust, dirt, etc. You can attach communications and use the sink only after the sealant has completely hardened (the time required for this is determined according to the instructions).

By following these simple rules, you can significantly increase the strength of the fastening.

Final stage

At the final stage, it is necessary to use another tool. To do this you will need a rasp or file, sandpaper, GOI posts, adhesive tape and a decorative corner made of duralumin.

Here the process is simpler and does not require special skills in working with tools. Yes, and millimeter precision and accuracy are not required here.

The first step is to sand the wood. For this purpose, you can use a rasp or file, with which you want to remove excess. After this, use a sanding machine or regular sandpaper (zero grade will do) to bring the wood into a nice looking state. It is recommended to carry out this work even if you are not going to do anything after it. Due to the torn elements of the wood, the material will attract moisture much faster, which will cause faster wear of the material.

Having brought the tree back to normal, it is necessary to bring the plastic to the same condition. Usually, the use of special polishes is sufficient for this. But if one is not available, then you should not buy a new one, since to process one tabletop you will need very little of this product, and then it would be a pity to throw away the polish, and it is not economical.

The ideal option for processing plastic is GOI paste. It is available in almost every home, and is an absolutely universal remedy and quite effective.

Even if the cutting was successful and the grinding was of high quality, it is still better to play it safe so that even small millimeters do not make themselves felt in the future. Therefore, it is recommended to use a special furniture corner made of duralumin for decoration. It should be attached to its place, while the appearance will become neat.

Rules for working with a jigsaw

To understand how to properly saw a circle in wood, it is important to study the features. This carpentry tool helps to cut out ovals, wavy patterns, figures with uneven outlines, non-standard carved boxes, shelves with end-to-end patterns

To ensure that interaction with a jigsaw is organized and safe, it is important to adhere to the following rules:

In order for work with a jigsaw to proceed quickly and safely, do not forget to fix the product before work.

- To avoid inconvenience, special stands should be prepared during work. A slot is made up to the middle of the support, somewhat reminiscent of a lock hole.

- The stand is fixed with clamps or screws to the workbench.

- At the time of work, you need to sit down, position the file strictly vertically relative to the floor and perpendicular to the surface.

- The workpiece is placed in the middle of the stand, holding it with your left hand; you can saw the plywood with your right hand. The location of the cuts should be in the middle part of the support hole.

- The tool does not tolerate strong pressure: just a small touch and gradual movement up and down, and it will begin to work effectively.

Attributes:

- pencil;

- drill;

- drill;

- jigsaw

What devices to use

A compass is used to cut out circles using a jigsaw. As a rule, it is supplied complete with the tool. There may be a separate compass, or a combined one, combined with a parallel stop. In the first case, just a compass is a plate with a sharpened cone at the end.

In the second case, a rip fence bar is attached next to the needle for straight cutting. Such universal stop compasses are not always convenient.

The bar can interfere with cutting circles of small diameter if it does not allow you to move the needle as close to the jigsaw as possible, which will prevent you from cutting a circle of the minimum radius.

The photo shows work with a combined compass-stop:

Factory models have two disadvantages.

- The size of the circle is limited by the length of the compass plate. If the length of the plate to the needle is 250 mm, minus 70 mm for fastening in the jigsaw platform rods, a radius of 180 mm remains. You can cut a circle with a maximum diameter of 360 mm (radius 180 mm);

- the needle does not fix the compass securely enough. During sawing, it can jump off the marked center, and then the cut will go crooked.

For more reliable fixation, holes are drilled in the workpiece for the centering needle.

When the factory compass is too short for cutting large circles, make a homemade one. Their advantages:

- you can choose a plate of any length, which means you can cut circles of any diameter;

- Instead of a centering needle, a hole is used into which a self-tapping screw is screwed, which ensures reliable fixation.

An example of how to make a homemade compass and work with it can be seen in the video:

An ordinary skewer was used as a plate. The centering hole should be directly opposite the file, so a small stem with a hole for the centering screw is screwed to the plate.

How to cut a hole

After the marking has been made, the hole needs to be cut. It should be accurate, but slightly larger in diameter than the sink bowl so that the sink can easily fit into it. To do this, you need to step back a couple of millimeters from the inner contour to the outside and make a cut along this line. This way you can achieve the necessary backlash.

Installing an undermount sink in the kitchen

You can use a jigsaw or drill to cut the hole. It will take longer to tinker with a drill, but this work is much easier to do with a jigsaw.