Many people, when choosing a chair, want it to fit into the interior of the room and be comfortable for sitting.

All this is good, but most models are not suitable for the human spine and contribute to the development of various diseases of the musculoskeletal system (MSD).

To solve this problem, the orthopedic knee chair was invented. This, of course, is not 100% protection against spinal pathologies, however, using the structure significantly reduces the risk of developing bone diseases.

History of appearance

In 1970, the Danish scientist Mendel observed and studied the postures of people leading a sedentary lifestyle, office workers, and schoolchildren. Considering the way they sit, he came to the conclusion that the most comfortable position for sitting on a regular chair is to tilt the body forward relative to the pelvis. It is this constantly repeated body position that leads to curvature of the spine and other back diseases.

For many decades, scientists have been trying to find a design that would fully meet all the requirements.

From this, he designed a chair whose seat was tilted downward by 15 degrees. This structure helped maintain correct posture, but had its drawbacks. A person sitting on such a chair constantly rolled off it.

The most useful chair is one whose seat is located at an angle of 15° relative to the horizontal.

A number of researchers from Norway became interested in Mendel's work and in the course of development, they improved the kneeling chair by inventing a knee rest. Thus, they were able to evenly distribute the load on the buttocks and knees, and the spine began to serve as the center of gravity. The body of the person sitting reflexively straightened at the slightest tilt forward.

The result was a chair with a footrest in a half-bent position, on which one stood with one's knees.

One of the developers of such a chair was the owner of the furniture factory, Peter Opsvik. It was thanks to him that such a chair hit the store shelves.

What materials is it made from?

There are only 2 acceptable types of raw materials from which a kneeling chair can be made: metal and wood. Products with a steel base are considered more reliable and durable. Chrome plating, special paint and Teflon coating provide reliable protection against the negative effects of external factors. Models with a similar frame can last for several years.

If you need a chair for a schoolchild, you can pay attention to wooden structures. They are lightweight and fit well into any interior.

Multi-layer plywood, beech or natural oak is usually used as a base. The latter is one of the most expensive materials.

The materials for filling the cushions, seat and soft back of the kneeling chair are:

- Foam rubber is characterized by good elasticity and affordable cost, but after 5–6 years it becomes unusable.

- Latex has good porosity and a high degree of elasticity, repels moisture and dust, and retains its qualities for 10 years.

An additional thin layer of padding polyester prevents the formation of wrinkles on the surface. For upholstery, leatherette, leather, or any durable fabric can be used. Many manufacturers offer replacement covers for purchase, which makes caring for the knee chair much easier.

Wooden frame Metal Fillings Fabric upholstery Leather

Leatherette

Replacement cover

Therapeutic effect

The knee orthopedic chair model allows you to adjust the seat height, adapting to everyone. With a correctly adjusted chair, the load is distributed approximately 60 to 40. Of this, 40 percent of the load goes to the knees and only 60 to the pelvis. This allows you to significantly relax your back muscles and take a comfortable position without tilting your body forward. Those. You will feel comfortable sitting on such a chair with a straight back.

A feature of the kneeling chair is the redirection of the load from the lower part of the spine to the muscles of the legs, while maintaining a vertical position of the back, the shoulders remain straightened.

Doctors and orthopedists advise purchasing such a chair for schoolchildren and students who have to spend a lot of time sitting in class.

Since its inception, when the chair had only a seat and a knee rest, its design has acquired many innovations.

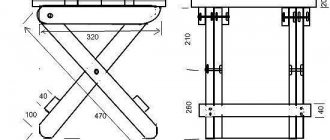

Drawing with dimensions

The design of an orthopedic chair consists of a seat and a knee rest, which can be solid or consist of two pads.

An important stage in the execution of the product is the preparation of the drawing. Specialists and folk craftsmen have developed many designs for kneeling chairs with standard sizes, but it is better to make them with sizes that will meet the needs of a particular person. How suitable and convenient the design is to use depends on a correctly executed drawing.

Advantages and disadvantages

Almost no invention is perfect, and even the most perfect design will have flaws and shortcomings.

Pros of a kneeling chair:

- posture improves;

- back muscles are trained;

- the load on the spine is reduced;

- prevention of scoliosis;

- blood flow to the lower body improves;

- the chest straightens, breathing improves;

Models with wheels and a back, with static support and in the form of a transformer, with an arched support that allows the sitter to swing, corset chairs appeared.

Minuses:

- the appearance of pain in the knee joints;

- it takes a period of getting used to;

- feet may go numb;

- possible slipping from the chair;

- it is necessary to adjust the chair for each person sitting down;

- unsightly appearance;

People who use this model of chair for a long time get so used to it that they no longer want to change to a regular one.

The most suitable model is selected taking into account the person’s weight, height, medical recommendations and individual preferences.

Although there are disadvantages, this does not mean that all of them will be relevant to you. Some people with bad knees do not experience discomfort or pain in the joints when sitting on an orthopedic chair with this design. It all depends on whether you distribute the load correctly and what model of chair you choose.

When choosing an orthopedic chair for a schoolchild or a person with musculoskeletal problems, you should pay attention to a knee-type chair.

Manufacturers, in pursuit of originality, come up with their own features that do not always have positive functionality.

The most important thing to remember is that when choosing an orthopedic knee chair, take into account your physiological characteristics: weight, height, chronic diseases.

Its design ensures reflex straightening of the back without stress on the muscles and joints of the spine.

Material selection

There are a lot of material options for assembling a chair, and it’s not just about choosing the type of wood. The main thing is to decide which lumber and what degree of processing will be used in the work.

When it comes to the type of wood that is used to assemble the home chair, it is best to look for hardwoods. For example, if it is a massive tree, then it is better to stock up on oak materials. Mahogany is also often used because it has a beautiful shade, especially after varnishing, and is also often used in interior decoration. Oak and mahogany are quite practical materials because they are distinguished by their durability. Sometimes pine lumber, as well as beech, is used to assemble home furniture with your own hands. The main thing when preparing wood is to use enough of it.

Each of these materials in the design of the chair performs certain functions. The legs of the chair, including the back ones as supports for the back, are best made from beams. Jumpers between the legs can also be made from boards

Special attention should be paid to the seat. Depending on its shape, you can use a single piece of wood or several boards. When working with solid wood, the seat is made solid, but this makes the chair heavier

It’s easier to use plywood or other ready-made tile wood materials as a seat.

When working with solid wood, the seat is made one piece, but this makes the chair heavier. It is easier to use plywood or other ready-made tile wood materials as a seat.

When selecting material, craftsmen proceed from the design features of the chair, which are indicated in the drawing, which will be discussed further.

The material requirements are as follows:

- they should be fairly dry, 22-23% humidity;

- edged, if possible, polished and free of cracks;

- beams with large cracks or extraneous holes larger than 4 millimeters are not allowed;

- rotten or overly knotty materials should also be rejected;

- The stronger the type of wood, the thinner the beams are chosen, while the optimal thickness of the beam is about 40 millimeters, and the boards should be thinner.

How to make a kneeling chair with your own hands

Despite the fact that the kneeling chair has a simple structure, prices in stores are quite high. Due to the fact that the description of the properties contains the word “orthopedic”, manufacturers artificially and unreasonably inflate their prices.

Sitting on such a chair, the back behaves the same as in a standing position.

You can make such a chair yourself. This does not require any supernatural skills or materials. You can find diagrams and drawings freely available on the World Wide Web. In addition, the kneeling chair you make yourself will correspond to your wishes and body features.

For children, orthopedic chairs with a knee support are simply irreplaceable.

If you have knee pain, you can make the knee support extra soft for greater comfort.

Drawing and diagram

To correctly select a ready-made diagram or drawing, you should carefully read the instructions that come with it.

First of all, having studied the available schemes, think about whether they meet your requirements. Based on them, you can create a drawing that suits you.

Many who want to become the owner of this piece of furniture decide to make a kneeling chair with their own hands.

The drawing must include:

- dimensions of parts;

- fastener locations;

- part with seat height adjustment.

All details must be drawn either in real size, or use scaling, i.e. change the size while maintaining proportions.

It is best to create a scheme with dimensions that will fully satisfy the needs of an individual.

Selecting Tools

Before you start creating an orthopedic knee chair, prepare a standard set of tools:

- Pencil or marker;

- Roulette or ruler;

- Drill;

- Screwdriver and screws;

- Saw or jigsaw;

- Grinder or sandpaper;

- Furniture stapler.

The choice of tools directly depends on the materials from which you will make your chair. It can be made not only of wood and plywood, but also of iron. In this case, you will additionally need a grinder or a metal saw and a welding machine.

Selection of material

- Plywood sheet;

- Hardwood bars;

- Upholstery fabric;

- Foam rubber or other filler;

- Fastening parts;

- Glue;

- Varnish;

- Paint and brushes optional.

Before proceeding directly to the manufacturing process, it is necessary to check the availability of tools and materials.

Most often, at home, such chairs are still made of wood and plywood. In rare cases, metal is used. Large manufacturers, in turn, on the contrary, give preference to metal samples.

Chair making process

In order to properly make an orthopedic knee chair with your own hands, you need to perform all your steps in stages.

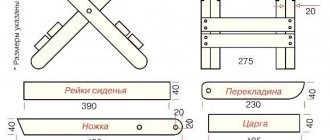

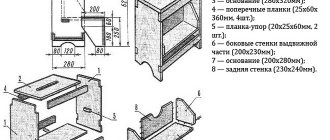

- All parts are cut from the bars according to the drawing. Vertical bars: two front and one rear. Horizontal: cross bars (horizontal legs). Part with grooves for height adjustment.

- All places for self-tapping screws are pre-drilled with a drill.

- We connect the individual parts.

- We attach cross bars, they will serve as legs.

- Two blanks are cut out of plywood for the seat and for the knees.

- We glue foam rubber on them and cover them with upholstery fabric.

- We attach the seat at an angle of 15 degrees to the front vertical bars and a support under the knees.

- Cover with varnish.

After completion of manufacturing, visible wooden structural elements are coated with varnish or paint.

It is best to use furniture dowels and wood glue when connecting parts. Self-tapping screws can be used additionally for reliability.

To prevent sagging of the soft parts of the chair, it is recommended to use several types of foam rubber of different hardness, gluing them on top of each other.

Step-by-step assembly instructions

Having prepared the pattern, materials and tools, you can safely begin to work. Remember - work does not tolerate haste and fuss. An experienced craftsman knows that it is necessary to measure several times, weigh everything and only then cut.

Stages of work.

We apply the pattern made according to the drawing to the plywood and cut out the first part of the side legs. It is necessary to make the workpiece with a small margin of a few millimeters. This reserve will prevent mistakes when cutting. Using a copy cutter, we bring the workpiece to the ideal size. We cut out three more legs with a margin. Stack all four legs. Using the first perfect piece, we grind the remaining three legs. This approach will save time on grinding. Glue two pieces together and let them dry. Using a router we make grooves on the inside of the legs. The groove dimensions should be 10 mm deep and 24 mm wide. This groove plays a key role in further adjustment of the positions of all elements. Exactly in the middle of the groove it is necessary to make through holes in which the seat and footrest will be secured. Holes must be made at equal distances from each other.

It is important to place a block under the leg when drilling to avoid chipping and deformation on the outside. We are preparing the runners. The slider allows you to fix the seat or footrest in the desired position

You will need 4 of them - two on each side. The sliders must correspond to the size of the foot and not look beyond it - height 20 mm and width 24 mm. All corners and edges of the runner are rounded, and a groove is made in the center. The gutter is intended for further gluing into it the slats, which will be inserted into the groove of the leg. The rail should be made based on the width of the groove into which it will be inserted on one side and the groove on the other side. The slider and the rail are glued together and dried. A hole is made in the slider for a bolt that will secure the selected position. Next, the back and footrest are cut out. The dimensions of the seat for a child are chosen independently and depend on his age and the calculated reserve. The shape of the parts can also be arbitrary - square, semicircular or oval. The next step is to make the back for the chair. The back can have a wide solid surface or be made of several slats of various sizes. Don't forget about the crossbar that secures the legs in their lower part. Finished parts are not assembled using the final method, but rather the baiting method. This will help evaluate the final result and identify flaws that need to be eliminated. If the chair for the child corresponds to the initial plan and drawing, it is necessary to disassemble it and begin final processing using sandpaper. We clean the surfaces, preparing them for painting. The paint color is chosen independently. Some craftsmen prefer to prime and then varnish, thereby emphasizing the existing wood pattern. Plywood, however, is best painted because it does not have a uniform appearance. The dried parts are assembled into a structure and are ready for use.

The seats, footrest and backrest can be made of 22 or 16 mm plywood.

These parts can be mounted using bolts and subsequently removed from the chair.

For studying at the school table, armrests are not needed, since the hands are always on the table.

A growing chair for small children can be additionally equipped with armrests and a safety front bar so that the child cannot fall from it. These parts can be mounted using bolts and subsequently removed from the chair. For studying at the school table, armrests are not needed, since the hands are always on the table.

The parts of the child's chair are fastened using hex bolts and furniture countersunk nuts.

Plywood, however, is best painted because it does not have a uniform appearance.

Operating rules

The main goal of orthopedic developments is the prevention and treatment of diseases of the musculoskeletal system. This chair was no exception.

The positive result after its use gives grounds for orthopedic doctors to recommend the knee chair to their patients.

An orthopedic knee chair is recommended both for healthy people who want to maintain their supporting apparatus into old age, and for patients with medical prescriptions.

Of course, it will not solve your problems, but if used correctly, it will greatly alleviate your posture problems.

In order for you to sit comfortably on such a chair, it is important to correctly adjust its height, namely the distance between the knee support and the seat itself.

Correct posture helps restore the natural curves of the spinal column in mild to moderate scoliosis, completely preventing its development in the future.

Also, do not forget to periodically get up from it and do a short walk, warm-up or physical exercise to improve blood flow in the lower extremities.

Kneeling chairs often take some getting used to. Start with 10-15 minutes a day, gradually increasing the time you sit on it. If you feel discomfort when sitting on this chair, and you can’t get used to it, give up this idea. Listen to your body.

Many owners of this wonderful invention recommend alternating its use with conventional orthopedic chairs so that the frequency of loads in the sitting position changes.

Decoration

Furniture assembly work ends with decoration. Before decoration, the surfaces are treated with sheets of sandpaper and coated with clear varnish. Decoration is carried out using the techniques of decoupage, patination, engraving, simple or artistic coloring, etc.

Wood carving allows you to create original patterns and engravings. The design can be contour, geometric, relief, etc. Fine carving will give the room lightness and airiness. After engraving, the product is coated with transparent varnish or thick paint. The design method is suitable for rooms in the Art Nouveau, Baroque, and Shabby Chic styles.

Antique chairs are decorated with your own hands using decoupage techniques. Furniture is complemented with floral prints or reproductions of art paintings, artificially aging the surface. The work is completed by varnishing the surfaces. The decor will suit rooms in retro, vintage, Provencal styles.

Coloring allows you to harmoniously fit furniture into the interior, making models contrasting or neutral. When applying enamel, it is possible to use patination techniques, stylization like marble and glass. Paints can be translucent or dense depending on the interior design.

Photos of 50 design options for orthopedic knee chairs

Benefits for whom it is recommended

An orthopedic knee chair allows you to straighten your back without much strain, at the level of reflexes. Maintaining the spine in an anatomical position does not require additional muscle tension and minute-by-minute control.

The advantages of this product are:

- creating correct posture and maintaining anatomical curves;

- improvement of respiratory function;

- reducing the load on the back muscles;

- reducing pressure on internal organs;

- establishing normal blood circulation in the thighs, since there is no pressure from the edge of the seat.

This type of furniture is indispensable for schoolchildren, students, people who spend a lot of time sitting (artists, architects, programmers, office workers, etc.). This design can be used by pregnant women in later stages.

A chair with knee support not only helps with the formation of posture in children, but also serves to prevent spinal problems in adults.

There are a number of conditions in which the use of a kneeling chair can improve a person’s well-being. These include:

- osteochondrosis;

- poor posture;

- unstable conditions of any of the vertebral sections;

- presence of hernia and protrusion;

- inflammation of the back muscles;

- recovery period after spinal injuries;

- scoliosis.

It has been established that problems of the respiratory and cardiovascular systems, disorders of the gastrointestinal tract, and inflammatory processes in the rectum can be partially smoothed out thanks to this device.

According to user surveys, positive changes appear after a month of use.

Device

The design of a saddle chair consists of a seat, a central leg ending in five arms. Most models are equipped with a backrest and armrests.

Saddle seat

The seat is the central ingredient of a similar chair. It is a saddle, the edges on both sides of which are beveled at an angle. In many models, the seat consists of two mirror-symmetrical parts. It is believed that the latter option is better for men.

- The pressure on soft tissues is reduced.

- Circulation processes are not disrupted.

- There is no overheating of the groin area.

For adjustment, the product is provided with levers. With their help, the angle of inclination of the saddle and the position of the halves in relation to each other are changed.

Article on the topic: DIY folding metal chair

The upholstery material is excellent leatherette. The variety of colors and textures pleases us. Instead of filler, high-density foam rubber is used.

Back

The back is an optional item. Most designs do not have it. Still, if it is available, you can sometimes give rest to the back muscles. The ergonomic shape of the backrest helps you securely fit into the chair. Manufacturers offer 3 shape options, which will allow you to choose the most convenient model.

To fasten the backrest, metal parts are used that are securely connected to the central leg under the seat.

Elbow support is provided by soft supports located on both sides of the backrest.

Base

The base is made in the form of a cross with five beams, each of them ends with an iron roller with a rubber rim. This ensures smooth and silent movement without damaging the floor covering.

The crosspiece with a diameter of approximately 50 cm is made of metal and is capable of holding serious loads. A protective coating of chrome or plastic is applied on top.

Changing the height position is done using gas lift. To do this, simply press a special lever to adjust the chair in accordance with the height of the person sitting. The correct position is considered to be one in which the elbow of the bent arm is completely located on the table top.

The lifting device is hidden in the support and is a metal cylinder 13-16 cm long. The internal volume is divided into 2 reservoirs, between which there is a valve.

Some chairs are equipped with a mechanism for rotation around the central axis by 360°.

The health of the spine directly affects a person’s overall well-being, so it is important to do everything to preserve it. An orthopedic chair saddle will greatly help in developing and correcting posture and will restore tone to the back muscles.

Types of filler

When purchasing kneeling chairs, attention is paid to this parameter. Because the filling affects the comfort and durability of the seat

Today there are two popular options:

- Foam rubber;

- Latex.

The peculiarity of the first option is sufficient flexibility, low price and hypoallergenicity. However, there is also a downside - a short service life, which is only 5 years. Latex is used for office products, as it has a high degree of elasticity and porosity. The material is antistatic, which prevents the accumulation of large amounts of dust. The average service life is 10 years.

The outer part is made of upholstery fabric, but leatherette can also be used. To prevent the formation of folds that spoil the appearance, a small layer of synthetic padding is used. It is also possible to use replacement covers; if you have the opportunity to buy them, it is better to do this before the chair gets dirty. Thanks to this element, you can choose a coloring to match any design.

Types of bases

Kneeling chairs have several types of bases.

The simplest and most affordable option is equipped with a stable support in the form of legs or slats.

The presence of wheels will ensure mobility. On such a chair you can easily move along the desktop or around the room without getting up from it. There will also be no problems moving the product, which usually has a lot of weight. To avoid damage to the floor covering, the rollers have a rubberized layer.

Curved runners similar to a rocking chair make it possible to balance and choose any position while maintaining the anatomical shape of the spine.

Now about the improvements

1. After upholstering the knee pads, the thought immediately came to me that making three rectangular pads would be much easier

2. I cut the planks into the support bars 20 mm, plus glue and confirmations. On the first pine chair we had to put corners, because my daughter somehow managed to loosen the glue.

3. I strengthened the part of the support bar that comes from the seat. That is, I have not 2 strips there, but 5. And they are also embedded into the beam by 20 mm.

4. I made the seat and knee pads composite. There is a supporting part, and there is the seat itself and knee pads already with foam rubber and covered. To connect the seat and knee pads, I inserted M8 bolts (M6 is also possible), the heads of which were filled with epoxy (you can use liquid nails or other reliable glue with filler).

5. Seat angle adjustment system. Already tried it and am satisfied. The chair became a little higher than before, and I had to change the height for my daughter using a bar. It was so easy to set a comfortable angle, which could not be done in the basic model. You can supplement the system with a series of holes along a different radius and thereby obtain an almost perfectly smooth adjustment of the seat tilt.

Well, I’ll just share where I found the beech. It’s easier for those who have such boards, but I couldn’t find them in my region. And I found beech steps in a large store and right there in the store they gave me one meter (1000*400*40, it seems) step on 40*22 slats and several 40*45 bars and I happily went home to make chair No. 2. And now I want to make chair No. 3, making the parts not prefabricated, but solid.

My daughter went to first grade and I see that the child’s seat in such a chair is really different than in a traditional one. The child has a straight back without any effort. For an adult, IMHO, you need to make a chair out of iron. I (100 kg) carefully sat down on the first pine chair, but there are still doubts that it would have supported me for a long time.

Let's move from theory to practice

According to the drawing, we need to prepare wooden blocks. Wood should be used without knots, preferably hardwood.

If you don’t want the chair to start creaking in a month, then use furniture dowels and wood glue to connect the beams.

The procedure for making a chair will take a little longer due to the long drying time of the glue. For reliability, additionally, the connections can be fastened with self-tapping screws or confirmations.

We cut out the seat and knee rest from 20mm thick plywood. And we attach it to the frame of the chair using confirmations and furniture dowels.

Of course, without soft upholstery it will be completely uncomfortable to sit on such a chair, so the plywood will need to be covered with foam rubber.

It is advisable to use several types of foam rubber, hard at the bottom and softer at the top. This is done so that the knees do not press through the soft foam rubber and do not rest against the hard plywood.

We cover the foam rubber with elastic decorative fabric.

For ease of movement, we attach wheels to the base of the chair.

Since we use a square beam at the base of the chair, and when unfolded the chair stands on its edges, to attach the wheels it is necessary to make a recess in the lower beam. To ensure that the wheels are installed strictly vertically, we place the chair in the unfolded state on the floor. We put a ruler on the side (a block 15-20mm thick), and from the end of the base of the chair, with a pencil we mark where exactly to make a selection for the wheels.

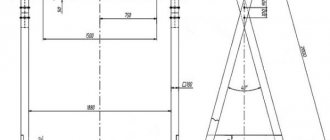

Assembly steps

- First, the bars for the front and rear legs are processed - 2 on each side. The front legs (400-500 mm) and rear legs (800-1000 mm), depending on the selected dimensions, are cut to match the drawing. In this case, the front and rear legs are folded together. If the rear legs have a previously prepared corner, then the front legs should correspond in height to the location of this corner. It is at this height that the seat should be located. After this, appropriate marks are made on the legs for the holes for the jumpers.

- The holes themselves are made with a chisel, based on the location of the prepared marks. In this case, all sawdust is removed from the hole so as not to interfere with the connection.

- Jumpers are created, and the front and rear ones should be the same length as the side ones. The dimensions of the jumpers correspond to the width and length of the chair, taking into account the thickness of the legs. In the jumpers you should also mark the places of the tenons that will connect to the holes on the legs. The width of the spike should be around 10-12 mm. They need to be cut carefully, taking into account the fact that they must be firmly and tightly connected to the legs. Gaps are not allowed.

- The back gets knocked down. It can be made from one board or from several. The production of the backrest occurs on the principle of creating jumpers, leaving spikes that must fit tightly and firmly into the rear supports.

- The seat itself is prepared, which also corresponds to the dimensions of the frame. It can be wider and hang over the legs and jumpers. At this stage, the seat is assembled from boards and used into a solid solid wooden piece, plywood or, for example, a chipboard. It can also be covered separately with fabric to provide softness. It should be noted that the seat is attached to the legs with self-tapping screws.

- All wooden surfaces are treated with varnish, preferably odorless. You can proceed to assembly only after drying. The varnish must be used in accordance with the manufacturer's instructions.

- Direct assembly of all frame elements, except for the seat: all the tenons are lubricated with glue, and then connected to each other using a rubber hammer or mallet so as not to knock off the varnish.

- At the last stage, the seat is screwed on using self-tapping screws. As a rule, they are screwed in quite deeply and masked with PVA mixed with sawdust. This mixture is applied to the caps, and after varnishing the screws are no longer visible.

Accessories

Each manufacturer produces a large number of accessories for its furniture:

- Stokke - infant seat with lying position, seat cushion, plastic tray and seat belts;

- Kid-Fix - high chair cushion and seat belts, as well as a table;

- The Little Humpbacked Horse - a large number of accessories, including a pocket for toys, a table with limiters;

- Kotokota - the only additions are limiters and a table.

Some are sold complete with growing chairs, others are purchased separately. The cost varies depending on the brand and material of manufacture. All accessories are also certified and meet safety requirements.

Details

Equipment

Today there are models on sale that are equipped with the following elements:

- Backrest for additional spinal support.

- Wheels for easier movement.

- With an arched support that allows a person to swing on a chair.

- With a static type support and one that can be changed.

When selecting a particular model of orthopedic specialized chair, it is important to consider the following:

- Individual human parameters (weight and height).

- Recommendations from doctors.

- Features and personal wishes.

pros

It also happens that due to prolonged sitting on a chair, the feet begin to become numb, and pain in the knees also appears. You can prevent discomfort if you take short breaks every hour.

Preparation of tools and materials

Orthopedic furniture items are sold in most retail establishments. But its price is sometimes so high that not everyone can afford to buy such a chair. You can also use alternative suggestions and make an orthopedic chair with your own hands. To begin with, during production there is no need to interrupt and delay the finale if you prepare all the materials in advance. It is advisable to have all the tools in the workshop, but it is still worth checking that everything is available. To make an orthopedic knee chair with your own hands according to the drawing, you will need to prepare:

Plywood sheets. Wooden blocks (it is important to give preference to hard wood). Upholstery fabric. Soft filler.

Next, let's move directly to the process.

Step-by-step instruction

Making an orthopedic chair with a knee rest will not be accompanied by any particular difficulties. But in order to prevent even small errors from appearing, you should be sure to follow these instructions:

From pre-prepared bars, blanks should be cut in accordance with the dimensions indicated in the drawing. The cross bars must be attached to the lower support, which acts as legs in the structure. A single bar should be installed on the back side of the backrest, and then connected to the seat support. Cut grooves on the bar through which you can adjust the height. Attach a base to the seat on which the knee rest will be attached so that it protrudes slightly forward. You also need to install a jumper for the grooves on the back. Using an electric jigsaw, you should cut out two rectangular shapes from plywood (the first will be used to make a seat, and the second will be a footrest). Cut out a couple of pieces of foam rubber, which are important to stick on the blanks. In order to give the seat a complete look, it and the footrest should be covered with upholstery fabric.

Making your own kneeling chair

Do-it-yourself forms for garden figures

A feature of Opsvik’s design is its simplicity. Essentially, this is a product with one seat and two knee supports. Sometimes the emphasis is continuous. However, the price of a kneeling chair is usually quite high compared to conventional models.

The simplicity of the design led to the fact that kneeling chairs began to be manufactured independently. At first, masters did this, but then ordinary people mastered the technique. A simple kneeling chair model is elementary:

- The structure is made of three sets of bars. One rear and two front vertical ones - to hold the main weight and two horizontal ones - to support the knees.

- You can connect the bars with mop sticks or similar devices. Even for a homemade product, the ability to adjust the height and tilt is important. This is ensured by additional holes in which horizontal bars will be attached. Which one is selected according to the height and weight of a particular person.

- The legs of the chair can be made from the remains of the beams, securing them with metal rings.

- The beams are covered with special overlays and sheathed with fabric. And the kneeling chair, in its simple variation, is ready.

But any simple or complex kneeling chair model must be made according to specially developed drawings, otherwise there is a risk of getting a device that is completely unsuitable for sitting.

Kneeling chair drawings

A modern kneeling chair is called a kneeling smart chair. The production of smart chairs is developed in many countries - from simple wooden models to complexly adjustable metal ones.

Today, finding a suitable drawing of orthopedic smart chairs is not a problem. There are many sites and forums on the Internet where people willingly share with those interested not only dimensions and drawings, but also tips on proper manufacturing and assembly.

The drawings are limited only by dimensions and planes; the material for the smart chair must be selected independently, depending on the purpose of the model.

Wood products are usually made for home interiors. But depending on the type of wood, there may be weight restrictions for the person sitting. You should not forget about this when making your own smart chair. For example, pine is one of the softest materials and it is difficult to talk about the strength of such a product.

For beginning craftsmen, there is the simplest analogue of a smart chair – a kneeling stool. Despite its simplicity, the stool is not inferior in orthopedic properties to other products. A more complex design is a knee rocking chair. This model is a favorite option among children.

In order to alternate work with rest, a complex kneeling chair can be made according to the drawings. Its peculiarity is two provisions:

- standard, for sitting at a table;

- reclining, for rest.

In a semi-recumbent position, the person’s buttocks are located on the knee rest, the back is on a regular seat, and the head and neck are on the backrest. You can also make a mobile smart chair with your own hands by attaching wheels to the legs.

When making your own, it is important not to forget about the softness of the knee pads and the seat itself. If you make them too hard, in addition to discomfort, this can lead to exacerbation of diseases - for example, osteoarthritis of the knee joints

Terms of use

Reviews about kneeling chairs from people are very different, but the only thing that everyone notes is that you won’t be able to slouch on such a device.

For maximum comfort, the chair must be adjusted depending on the height and build of the user. Almost all models have at least 3 positions. The shorter a person is, the shorter the distance between the upper and lower pillow should be.

The table must be selected individually. This can be checked very simply: sitting on a kneeling chair, you need to clasp your hand at the elbow and move it away from the body by about 15 cm. The distance between the elbow and the floor is exactly the height that the table should have. A correctly selected piece of furniture allows you to provide the necessary distance between the computer monitor and a person’s eyes.

During work, the chair is moved towards the table so that the elbows are not in a hanging position, but lie on the tabletop.

It is recommended to place the computer monitor in the middle of the table so that constant turning left or right does not cause strain in the neck. The eyes should look directly at the monitor, neither down nor up.

But even an ergonomic chair does not relieve the computer user from the need to periodically warm up, at least every 40-50 minutes.

How long should you do the chair exercise?

At first glance, it may seem that the “chair” exercise is very simple to perform, but it is not so. In fact, when performed correctly, beginners give up within the first 10 seconds, while more trained people only need 30 seconds.

In the first stages, perform the exercise for as long as possible, but remember the main rule that guarantees success: you need to increase the time every day. Ultimately, you need to ensure that you are able to stand in the “chair” for a minute, doing it 4-5 times every day.

Now I will tell you what will change in your body if you do the “chair” every day.

Peculiarities

Orthopedists have developed many types of preventive chairs.

They help relieve the load from the lower back and neck, distributing it to the rest of the skeleton. The body weight falls on the pelvic, hip and knee areas. The heaviness is concentrated not on the tailbone, but on the entire spinal column.

This position is considered physiological, reminiscent of a natural standing position for a person . There is no need to strain the muscles: the vertical position of the back is maintained, and the shoulders remain straightened.

Help : since the orthopedic model arose, the design has been supplemented with many innovations. There are options with wheels and a backrest, with a static support and an arched one that allows you to swing on a chair, as well as corset chairs.

The model is selected according to the person’s weight, height, doctor’s recommendations and preferences . Kneeling chairs are used for therapeutic purposes for the following diseases:

- arthrosis and arthritis;

- osteochondrosis;

- hernia;

- scoliosis and kyphosis;

- kidney disease;

- haemorrhoids.

For children, such an orthopedic attribute is simply necessary when the musculoskeletal system is growing and developing, and incorrect posture at the table contributes to the development of curvatures and other pathologies. The kneeling chair has many advantages:

- the load on the lower back, sacrum and coccyx is reduced;

- prevents the development of spinal curvature;

- forms the habit of keeping your back straight;

- the shoulders and chest straighten, which helps the full volume of oxygen enter the lungs;

- pressure on the digestive organs is reduced;

- It is recommended to use it even for pregnant women who feel comfortable sitting on it;

- easy to make yourself.

Important : orthopedists recommend using the knee chair for schoolchildren, students, office workers, artists, and pregnant women.

Causes of poor posture

Posture begins to develop from childhood, since in schools students are forced to spend a lot of time on ordinary chairs. 75% of the load of the entire body weight falls on the pelvic intervertebral discs, only 25% falls on the legs. Children most often do not control the position of their legs, as a result of which curvature of the spinal column is observed. The same situation is observed in adulthood, the situation is aggravated when sitting cross-legged.

Causes of spinal curvature:

- Congenital diseases;

- Weakened muscles;

- Frequent stressful conditions;

- Sedentary work, sedentary lifestyle;

- Incorrectly selected, uncomfortable shoes;

- Excess body weight;

- Excessive physical activity;

- Unsuitable mattress.

Congenital diseases Weak muscles Stressful conditions Sedentary work Uncomfortable shoes Excess body weight Physical activity Unsuitable mattress

Posture develops throughout life; prolonged sitting at a desk poses a danger to the spinal column. Creating comfort for the child will help to avoid scoliosis and other back diseases.

When choosing a chair for a child, the following features should be taken into account:

- Possibility of adjustment - the baby grows, his skeleton changes, the ability to change the seat will help prevent problems with posture and vision;

- Lack of armrests - relying on them contributes to the curvature of the spinal column, and headaches can occur as a result of tension in the cervical vertebrae;

- The upholstery fabric material is quite practical and hypoallergenic; preference should be given to models with removable covers;

- Safety - all parts must be of different quality, sharp corners should be avoided, before purchasing you need to check the reliability of the latches and wheels; weight compliance - standards are specified in the instructions.

What is orthopedics?

Many people confuse the orthopedic properties of a chair with comfort, but these are different things. Comfort and convenience for the body are an important function of chairs and armchairs. But even the most comfortable of them can lead to poor posture and the formation of scoliosis.

When sitting correctly, a person does not have to stretch his neck or tilt his back or bend in all directions. His muscles do not become stiff and his lower back does not hurt. And sitting on such a chair will not lead to health problems in the future.

What kind of chairs can be called orthopedic?

Modern orthopedic chairs are office chairs with adjustable height and reclining backrest. They allow a person to relax, sitting comfortably, but during work they continue to have a negative impact on posture and internal organs. Sitting in such a chair, a person has to monitor the position of the body himself.

Desks for children are also considered orthopedic. They have everything you need for healthy posture:

- comfortable seat;

- back;

- footrest (which is very rare in orthopedic chairs);

- The tabletop is located at an angle.

Nevertheless, the majority of children suffer from scoliosis.

Observing schoolchildren, you can easily notice that at first they sit correctly. But after 30–40 minutes, the body begins to slide to the edge of the seat, the legs move from the footrest to the chair, and the child practically lies with his chest on the desk. This happens because he is trying to take a physiological, comfortable position.

Seat filler

The following materials are used as filler for the seat, backrest, and knee cushion: polyurethane foam, foam rubber, latex.

- Polyurethane foam is characterized by high stability, elasticity, and durability. The service life reaches 8-10 years.

- For these purposes, foam rubber with a density of at least 25 kg/m3 is used. It is not so susceptible to deformation and abrasion, and is designed for approximately 5 years of operation.

- Latex can be found in expensive models. It has the best characteristics and will last up to 20 years. However, the price of natural material is quite high.

All fillers are breathable, hypoallergenic, and do not accumulate dust. In order to improve performance characteristics, materials of different densities are combined.

In classic models, the thickness of the soft layer is 5 cm, and in luxury products it is 8 cm.

For exterior decoration, natural leather, its artificial analogues, and fabric materials are used.

- Upholstery made of genuine leather looks beautiful and solid, and will last for decades with proper care, which is not difficult. However, the price of such chairs cannot be called affordable, and the slippery surface further contributes to the body sliding.

- Eco-leather has similar characteristics, is cheaper, and has more color and texture options. But this material is less durable, so it is not as durable.

- Fabric upholstery is available in a wide variety, which makes it possible to easily choose a kneeling chair in accordance with the style of the interior. Please note that some fabrics are difficult to clean, so it is worth equipping the seat, backrest and knee support with removable covers. This approach will help keep the products in perfect condition.