Calculation of façade weight online

Facade material

MDF in film or plastic Laminated chipboard Acrylic glass on MDF Glass in an aluminum frame Solid oak Solid beech Solid alder

Facade dimensions

Please note that the calculation does not take into account the weight of the fittings (handles, hinges and mechanisms). To calculate the weight of the facade, the average value of the material density is taken.

Use the service to draw drawings of additives for facades.

To ensure maximum comfort when preparing food and working in the kitchen, the quality of movement when opening and closing facades is extremely important. This, in turn, is ensured by properly selected and installed fittings.

In order to correctly select lifting mechanisms or determine the number of hinges required, you need to know the façade or door design as accurately as possible. But, unfortunately, even the furniture manufacturer does not always know this treasured meaning for sure.

The most reliable and most accurate way to determine the weight of a facade is to weigh the facade on a home or other scale, but this is not always acceptable. For such cases, the weight of the facade is calculated using the formula:

FG = FH x FB x FD x Density, where:

To calculate the weight of a facade made of chipboard and MDF, the density value is equal to:

Please note that this formula determines the weight of the facade without taking into account the weight of the handle. To correctly select the power mechanism, it is necessary to take into account the weight of the handle, and for lifts of the HK, HK-S and HK-XS series it is necessary to take double the weight of the handle.

To select Blum components, in the full catalog in the “Information” section you can find a table of values of the approximate weight of the facade without a handle for facades made of chipboard, MDF and Aluminum frames with glass of standard sizes, 19 mm thick.

You can download the electronic version of the catalog using the link and add a printed version of the catalog to any order in our online store, completely free of charge.

To calculate the weight of a part, please select a material.

Enter the dimensions - width, height and thickness of the part.

Click on the "Calculate" button.

The information is for reference only, for values based on materials MDF, chipboard, Oak, Pine, an error within 10% is possible.

When choosing a lifting mechanism for a facade, take into account the weight of the furniture handle; in intersecting areas, choose a mechanism with a higher load capacity.

Source

Factors influencing the weight of an interior product

Other factors also influence the weight of the door:

- Dimensions of the canvas (length, width and thickness). Models made of the same material, the same height and width, but differing in thickness by several millimeters will have a difference in weight of several kg (depending on the material);

- Uniformity of the material. Products can be solid and glazed, made from one material or contain a combination of materials with different densities. All these nuances are reflected in the mass of products.

- Its production technology:

- The heaviest doors will be solid wood doors, whose weight can reach 140 kg.

- Slightly lighter than panel type products. Interior doors made of veneer contain fragments of wood materials (chipboard, MDF). The upper part of such products may contain inserts in the form of panels, glass, or cardboard with a cellular structure. The heaviness of the model will depend on the quality of the insert. It ranges from 20-40 kg.

- Panel products have a hollow structure. The cavities are usually filled with cardboard inserts in the form of a honeycomb. These models are distinguished by their low weight - 10-15 kg.

- The quality of the fittings used. Door handles, locks and other accessories add more weight to the product.

Calculation of façade weight online

Facade material

MDF in film or plastic Laminated chipboard Acrylic glass on MDF Glass in an aluminum frame Solid oak Solid beech Solid alder

Facade dimensions

Please note that the calculation does not take into account the weight of the fittings (handles, hinges and mechanisms). To calculate the weight of the facade, the average value of the material density is taken.

Use the service to draw drawings of additives for facades.

You can also order any furniture facades from us at prices from the manufacturer.

Manufacturing materials

The decisive factor for the weight of the product is the material of manufacture.

- Solid wood is the most expensive, but also the most attractive material. The door leaf in this case is made of a solid wooden panel and is distinguished by excellent heat and sound insulation. However, it has maximum weight. On average 1 sq. m of array weighs up to 20–25 kg. The higher the hardness and density of the wood, the heavier the product made from it. The heaviest ones are oak doors. The photo shows an oak interior door.

Characteristics of MDF

Each enterprise produces MDF boards using various technologies and dimensional standards that determine the technical characteristics of a particular product. Thus, the weight of the sheet will be influenced not only by its size, but also by its density. This indicator ranges from 600-850 kg/m³. The average density of the panels is 780 kg/m³.

Initially, MDF board looks like this, but the final product depends entirely on the finishing

Another criterion that affects the weight of the product is the presence of the outer covering of the slab, as well as its type and thickness. This can be one-sided or double-sided lamination with PVC film, laminating with paper film, or veneering with natural wood.

For example, wall panels have a protective and decorative coating on one side, and MDF boards, intended for the manufacture of various relief products (furniture facades, doors, decorative interior items, etc.), are simply produced with a polished surface, which makes it possible to carry out necessary milling operations.

The application of one or another coating is carried out on ready-made elements. There are also different types of MDF with a double-sided finish, most often used for making furniture.

What determines the mass of the product?

The weight of an interior door directly depends on the quality of the material from which it is made. Factory models are manufactured in accordance with state standards and have standard parameters: size and weight.

Materials, in turn, have such a property as density. The specifics of the material from which the product is made directly affects how much the door weighs. Here are the densities of the most common materials:

Average weight of a door made of this material, kg

1.5 kg per linear meter

Glass (thickness 5 mm)

Coniferous wood processing products

hardwood tree

Calculator

Specify just one parameter!

Due to the fact that prices are constantly changing. The exact cost of the goods will be indicated when you issue an invoice.

| Dimensions | 2070x2800 |

| Sheet weight | 90.3 kg |

| Sheets per pack | 28 |

| Manufacturer | Kronostar |

| Material | MDF |

| Modulus of elasticity at static bending, not less | 1700 MPa |

| Specific resistance to tearing of the outer layer, not less | 0.8 MPa |

| Formaldehyde content | ≤8 mg/100 g.s.m. |

| Content of mineral impurities | ≤0,2 % |

| Humidity | from 3 to 10% |

| Maximum thickness deviations | ±0.3 mm |

| Maximum deviations of length and width | ±5 % |

| Deviation from right angle | ≤2mm/m |

| Edge straightness deviation | ≤2mm/m |

| Tensile strength perpendicular to the plane, not less | 0.55 MPa |

| Swelling in 24 hours (for MDF, HDF boards), no more | 10 % |

| Density | 720÷980 kg/m3 |

| Bending strength, not less | 18 MPa |

hood for a heating boiler in a private house

MDF Kronostar is a board made by pressing wood fiber with the addition of a binder. It is characterized by high strength, density and durability. The material is environmentally friendly, aesthetic, easy to process.

MDF is easy to process in any way. Sheets can be covered with decorative film, painted, varnished, or laminated. Thanks to its flat, smooth surface, the material can be used to level walls and floors. But most often MDF is used in the furniture industry. It makes beautiful interior items that have a long service life.

Order MDF sheets with delivery throughout Russia in our online store. We offer a wide range of wood-based panel materials wholesale and retail. Please note that the exact cost of the item will be calculated when you issue the invoice.

Calculation and assembly of the RIAL.PRO suspension system

The Russian manufacturer RIAL.PRO produces systems for sliding wardrobes with different types of door installation. In addition to traditional bottom-support systems, the range includes three systems in which the doors move along an upper guide. They are used to create built-in and cabinet wardrobes. These can be two-door and other interior items. But most often hanging doors are installed when creating wardrobes and interior partitions.

We talked separately about how to assemble the lower support system. Now let’s pay attention to suspended and threshold-free structures that can be assembled based on branded products.

Unique hanging systems RIAL.PRO:

In general, the components and stages of assembling furniture based on a branded aluminum profile for sliding wardrobes are similar. Let's look at the features of a hanging door based on the Rial system.

Characteristic

MDF, what kind of material is it? This material owes its name to the British. It was they who came up with MEDIUM DENSITY FIBERBOARD - MDF.

The use of MDF panels, the wall dimensions of which are quite varied, is to perform finishing finishing work using this building material.

No renovation of an apartment or office can be done without them. Public institutions also widely use MDF, which is easy to use and easy to cut and install. It also reacts neutrally to temperature changes and the influence of direct sunlight.

The composition of the material is also beyond doubt. What is better for furniture, MDF or chipboard? Unlike chipboard, which contains more chemical components, MDF is produced using materials that are harmless to human health. The basis of MDF is crushed wood.

Assembling wardrobe doors

To install hanging doors, a standard set of tools is used. The façade is filled with laminated chipboard, MDF, mirrors and glass.

What you need to know to properly install Rial system doors:

To calculate the height of the door, an estimated additive is used. The height depends on the distance H (H is the height from the top to the bottom cover of the housing). If this dependency is not met, the system will not function.

Before you begin installing the profiles, you need to take care of the correct design of the cabinet itself. We offer a diagram that will help you correctly calculate the body:

Profile installation:

- When installing the RP 10 profile, the protrusion on the back of this profile must lie flat against the bottom of the cabinet.

- The running profile is placed on the cabinet lid and secured with screws.

- A large extension RP 07 is installed on the side wall of the cabinet.

Using the Rial system as an example, we will show how the door components are assembled:

- 16 mm chipboard and 4 mm glass are used. Chipboard is installed in the dividing profile RP08. In this case, the protrusion of the chipboard in relation to the profile should be the same.

- Next, install the silicone seal into the RP08 profile in pieces of the same size (4–5 cm) every 5 cm.

- The inserts are connected to each other using a separating profile RP08. In this case, the protrusion of the profile in relation to the insert is the same.

- A plastic insert for glass RP11 is inserted into the groove of the RP01 handle. This is done for additional fixation of the 4 mm glass insert (according to measurements).

- The tightness of the profile joints is checked using a mallet. The mate is aligned along the length.

- The handles are fixed to the inserts. In this case, a minimum of 2 screws per insert is used.

- The rollers are marked according to the additives. The rollers are fixed to the inserts.

- The corners of the front and rear doors are also marked using additives.

- The stopper is installed on the rear door roller.

How to install a front door closer:

How to install a closer for an internal door:

Door hinge:

- The support block is installed on the inside of the side walls of the cabinet. This eliminates the deflection of the RP05 profile into the inside of the body.

- The end stops are installed according to the additives.

- Before installing the doors, you need to check the geometry of the cabinet by applying the profile to the furniture body

- The front door is installed in the internal grooves of the running and guide profile.

- The latches are moved to the closed position.

- A small addition is installed following the example of a large one.

In addition, we suggest watching a video that shows in detail how the doors of the Rial system are installed and hung.

Head office and sales department

111399, Moscow, st. Elektrodnaya, 2, building 12-13-14 Tel.: +7

Source: rial.pro

Features of MDF panels for walls

Decorative wall panels come in a wide range of shapes and sizes, which directly affect their weight. There are three main types of sheet materials for wall decoration:

As for color and texture finishes, the choice is almost limitless.

For example, one slatted panel 6 mm thick, with a length of 2600 mm and a width of 150 mm, weighs 1.9 kg. With a similar thickness and length, the weight of a 200 mm wide panel will be 2.75 kg, and a 240 mm strip will “tighten” by 3.3 kg.

Width

The standard panel width is 150-190 mm; it is very rare to find 900 or 1200 mm MDF on the open market. The width largely determines the aesthetics and decorativeness of the finish: the wider the panel, the fewer joining seams on the coating and the smoother the surface appears.

The external dimensions and thickness of the panel play a key role. Weight according to dimensions is given in the tables above.

Let's see how the weight of an MDF panel measuring 2,800*2,050 mm (the maximum value on the market) will change, depending on the thickness of the product:

- 3 mm – 16 kg.

- 6 mm – 31 kg.

- 12 mm – 60 kg.

- 22 mm – 106 kg.

- 28 mm – 142 kg.

It is worth noting that the weight of the decorated panels will vary slightly upward.

Advantages

The convenience of using MDF lies not only in ease of installation, but also in the ability to choose the optimal sizes of wall panels so that there is less waste during the installation process.

where can you insure an apartment in Yekaterinburg

Please note that a specific manufacturer may produce MDF in its own line of sizes. The choice of manufacturers is quite diverse. Therefore, to purchase MDF with a certain height and width, you can study offers from different manufacturers. And be sure to choose what you need.

› Additional features

Online calculator

For your convenience, we have developed an online door calculator in which you can:

- • select the type of door and indicate its dimensions;

- • choose the type of glass and its decoration;

- • select accessories;

- • make an accurate cost calculation (excluding delivery to your city).

After receiving your application, we will contact you during business hours at the specified telephone number.

Free consultation with a design engineer

Consultation with a qualified specialist will help you in case of:

- • if you do not know how to choose the appropriate type of glass or set of fittings;

- • if you have a complex or non-standard project;

- • if you need to make an accurate cost calculation;

- • if you have any other question about glass doors.

After receiving your application, we will contact you during business hours at the specified telephone number.

Call a surveyor

You can call our specialist to carry out professional measurements:

- • to calculate the exact dimensions of the doorway;

- • to conduct an inspection of the installation site of the door and its fastening;

- • to receive recommendations on the choice of fittings and method of fastening;

- • to take into account other features of the installation site and further design of the structure.

After receiving your application, we will contact you during business hours at the specified telephone number.

Painting

In order to cover the panel with soil, it must be specially prepared. It doesn’t matter what size the wall MDF is. The next step is to powder coat both sides of the surface. To apply paint, it is necessary to ensure the appropriate temperature.

Painting will provide a surface with a high level of strength. It will be smooth and will not delaminate when the temperature rises or is exposed to moisture.

It is the use of powder painting that can create an attractive appearance of MDF panels with the durable use of this finishing material.

Painted

Strength and wear resistance are the distinctive features of MDF, the sizes of which are presented in a wide range. We can say that there are no restrictions in choosing the right size. Moreover, the cost of such materials is much more affordable than natural wood.

What material will help create an interior partition? In order to separate the space between rooms, glued, slotted panels are used. They can consist of many elements and, when assembled, look like a panel. This way you can successfully divide the space for work and leisure into zones.

Numbers

The bare mass indicators of different types of structures speak for themselves:

| Plastic with glass up to 35 kg | Metal-plastic up to 40-45 kg | For an apartment 45-60 kg |

| With thermal break up to 80-85 kg | Fireproof up to 130 kg | Armored up to 150 kg |

Products from the Middle Kingdom can be very light - only 40-45 kg. However, you can open such a canvas with an ordinary can opener without much effort.

How to choose the right one

The entrance area must not only be well protected from breaking and entering by thieves, but also made attractive. The hallway is always decorated in a certain style, so the door should fit into it as organically as possible. Or be bright - this option is often chosen by lovers of contrasts.

To choose the right door, follow these rules:

- Finishing. Products finished with powder paint look inexpensive and stylish (experiment with textures - crocodile, silk, moiré, hammer effect, and colors - any shade from the RAL catalogue). An economy class option, almost weightless, while giving the entrance area a sophisticated look - vinyl artificial leather on foam rubber. This is an ideal solution for entrance doors to an apartment. For a private home, thin (10-15 mm thick) MDF panels are suitable.

- Thermal insulation. For apartments located from the second floor and above, it is not necessary to insulate the entrance. But, if you really want, you can order the canvas and box to be filled with expanded polystyrene (foam plastic). This thermal insulation material weighs nothing.

- Quantity of sheet steel. For both a private house and an apartment, a sheet of 1 sheet, a frame and stiffening ribs is quite sufficient.

- Accessories. Choose the one you like. There is no point in saving on grams.

- Locks. For good protection, always order 2 mechanisms - cylinder and lever, and in addition to them an internal latch.

Calculating the approximate weight of the door is easy. Multiply the mass of 1 m2 by the area of the canvas, add the box and fittings.

offers customers custom manufacturing of entrance metal structures of any complexity. For detailed information, call the phone number listed on the website.

Scope of application

The exceptionally positive performance properties of MDF, coupled with environmental friendliness and affordability, have led to the popularity of these boards in a wide variety of construction, interior decoration and industrial sectors. The wide range allowed the panels to be widely used during repair and finishing work, as well as for the manufacture of furniture.

The ability for sound absorption and thermal insulation led to the use of the material for the production of wall plates, doors, interior partitions and other decorative elements.

MDF, due to its high density, is considered the optimal material for the production of joinery products. The panels are also used for rough laying of floor coverings and final leveling of walls. And, of course, the panels are widely used in the creation of office and cabinet furniture.

Hygroscopicity and resistance to mold and fungi have led to the fact that the boards have become popular in the production of furniture for medical institutions, laboratories, as well as living rooms with high humidity levels (bathrooms and kitchens).

The scope of use of MDF is wide and varied:

When using panels, the parameters of length, width and thickness of the material come to the fore. If there are practically no restrictions for wall cladding (the size of the slabs depends on the personal preferences of the owner of the room), then for other categories the area of application requires specific dimensions:

The material belongs to the category of wear-resistant, but it has been noted that it becomes morally obsolete before it wears out physically. That is why it (in the vast majority of cases) is used for cladding non-residential premises: hallway, corridor, bathroom, loggias and balconies, as well as utility blocks.

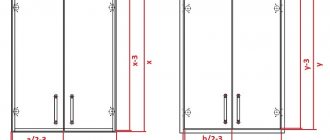

What to consider when calculating the dimensions of furniture facades

I have already written about how to calculate the dimensions of the fronts of a corner cabinet here. Now we will talk about ordinary ones.

There are two types of facades - overhead and inset (internal).

According to the generally accepted standard, overhead facades of any furniture and any plan (hinged, retractable) should be reduced by 3-4 mm from the dimensions of the cabinet/niche that they cover. The same rule applies for internal facades, but the calculation is based on the internal dimensions of the niche.

To be honest, I am calm about deviations from generally accepted norms in the calculation of furniture facades. The beauty of making furniture yourself, either with your own hands or to order, is that you can implement some non-standard solutions.

Is it possible to make the gaps on the facades smaller?

I remember there was a customer who really wanted the kitchen facades to fit very tightly together, forming a kind of monolithic effect. Moreover, it was important to him that the edge of the facades be as straight as possible, without roundings. For this reason, MDF facades were rejected immediately. He was categorically not satisfied with how the edge of PVC with a thickness of 2 mm and even 1 mm was “rounded”.

PVC with a thickness of 0.4 mm was purchased specifically for it.

The size of the fronts was reduced by only 2mm, excluding the thickness of the edges. The customer personally checked and approved all the dimensions of the facade that went into production - the appearance of the furniture was so important to him. Well, of course, I was warned about the minimum play for opening doors and drawers, in order to avoid them shuffling away from each other. The most subtle point was the large drawers at the bottom of the kitchen. It is natural that they sag a little, once they are loaded to capacity. They are regulated when the kitchen is installed empty. And loaded ones may well “climb” onto each other and begin to shuffle when opening, if the play between them – in his case only 1 mm – is minimal. But the customer vowed not to overload them and not to make any complaints about this.

Is it possible to make the gaps on the facades larger?

There was also the opposite case in my practice. When huge gaps between the facades emphasized the special design of the furniture. It looked really very interesting and stylish. I only have a photo of the shoe rack and it’s not in very good quality. But the principle of calculating cabinet facades is visible from the photograph.

The furniture body also adapts to such design techniques. So that the gaps between the doors, through which all the insides “shine,” are not visible.

There is one caveat if you want to use the same solution - make the doors smaller relative to the body so that the sides are visible. If the facades are hinged, then they are mounted not on a regular 90-degree hinge, but on a semi-overlay hinge, specially designed for opening at the “half end”. You can read more about loops here. Accordingly, the doors need to be reduced by the amount of “half the end”, that is, 8-10 mm.

For drawers, the size of the fronts, while significantly reduced relative to the edges of the niche, does not in any way affect its ability to slide out.