When the phrase “wooden box” is mentioned, many people immediately imagine a standard fruit box. Although in fact boxes can be very different and used for all sorts of purposes.

This is a very useful product that can be used in everyday life, not only somewhere in the country, but also just in the house. Let's figure out how to make a wooden box with your own hands, because only a homemade thing can be not only unique and as convenient as possible, but also completely safe.

DIY wooden box

Necessary tools and equipment

Before you begin your wood box project, you need to gather all your tools and equipment in one place.

We will need a machine for processing wood; a jointer and a circular saw must be present. Otherwise, we buy the strips we need in the store - size and thickness. You can’t do without a pencil, tape measure, construction angle and hammer.

We will use the machine for unprocessed wooden blanks, which we will make from boards 2.5 x 25 x 150 cm.

Car tires

Yes, those same old rubber tires are also on our list of ideas for creating containers for flowers. But you shouldn’t grimace when you mention these words in a conversation about site design. Here, as in any other matter, the main thing is not to “overdo it”: paint the tires, but do not make patterns - the “native” texture of the wheel will be enough. Place such containers in one place, thinking through the composition.

If you are against the “tire” design and are going to get rid of old tires, do not burn them under any circumstances, but rather take them for recycling to a specialized center.

What materials are used to build structures?

Most often, boxes are made of wood and other materials. For instruments, it is better to choose solid pine or maple. Alder or aspen is suitable for products. These tree species are distinguished by their durability and strength. They do not emit resinous secretions and do not dry out over time.

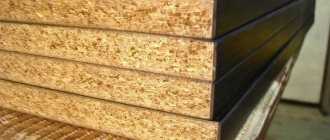

Plywood is suitable for making decorative products. You can place all sorts of little things here. To fix the parts, a special adhesive composition is used.

Tool used

Depending on the selected material from which the box will be made, the appropriate tool is selected. This should include:

- jigsaw and jointer;

- grinder and welding machine;

- hand tool.

Naturally, when making any design you cannot do without a measuring tape and a pencil.

We looked at how to make a box yourself from various materials. This design is distinguished by its simplicity and does not require special knowledge or experience from a person.

To make it, it will be enough to show attention and have the necessary skills in handling hand tools.

Homemade boxes are distinguished by their durability and ease of use. Their production does not require significant financial investments, which adds to their popularity.

Finally, about skirting boards

What can be made from lining, let's talk a little about skirting boards:

- If we have scraps of more than ten centimeters, we will get a decent plinth. This could be a part of the floor, wall or ceiling.

- And given all the complexity of such a material as lining, it can turn out quite interesting, especially if you paint the parts in different colors.

- Especially if we are talking about high-quality forcing, the elements of which ideally fit each other in width.

And if this is eurolining, then its elements can be perfectly laid using specialized locks.

Master class on creating a box with your own hands

We offer step-by-step instructions on how to make a box at home. To do this you will need the following tools and materials:

- tape measure;

- a simple pencil;

- board 25 mm thick;

- wooden edges 15 mm thick;

- thin plywood;

- metal corners;

- nails and screws;

- hacksaw;

- screwdriver;

- metal hinges for opening the lid structure;

- hammer.

First of all, you need to familiarize yourself with the diagrams and drawings of how to make a box. This will allow you to correctly compare the dimensions of the finished product. You should not make too large structures, as they will take up a lot of free space.

When all the components are ready, you can proceed to making a storage system for vegetables and fruits. The process includes several stages:

On the surface of the boards we mark the size of the side parts of the product. Next we move on to the bottom of the box. We mark the size on the wooden edges. After this, using a hacksaw, we begin to cut out the blanks.

We fix the boards together using small nails. We attach the bottom parts using the same method.

The cover of the product consists of a plywood sheet. It is installed on special hinges that allow you to control the closing process.

The photo of the DIY box shows the entire work process.

Product options

There are many reasons to make your own laundry basket. Firstly, you can choose the style of the product. Secondly, there are no size restrictions. Thanks to this, you can profitably use the free space. Thirdly, such a functional element will be much cheaper than those offered in a hardware or furniture store.

You can place the finished basket for dirty laundry in the dressing room, bedroom, bathroom, hallway or closet. In any case, now the untidy mountain of clothing will be camouflaged, and small items of clothing do not need to be searched throughout the house to wash.

There can be many options for manufacturing:

- standard laundry container in the form of a round or square basket;

- corner drawer, which allows you to make maximum use of space in the house thanks to its shape;

- the wall version is suspended on special mounts, you can even create a multi-level system;

- The collapsible basket is functional and can be hidden away in a closet or pantry when not needed.

Basket

Corner box Wall option Folding basket

Stages of work

How to make a wooden box with a lid? There is no point in buying or ordering it. And it's not interesting. You can do everything yourself. There is nothing complicated here, just follow the instructions. You have to do the following:

First you need to cut the bars to the length you need them. This will be the basis for the future box.

To create a three-dimensional frame, you need to combine these bars with each other. You will need nails to connect.

Next, calculate how many drawer slats you will need. They need to sew up the bottom and sides.

Professionals in their field advise to sew the bottom first, and then connect the sides. This way you can never go wrong with the size. When working, be sure to use a construction angle.

Also, if you plan to often use the box for storing vegetables, it is best to cover the caps with putty. This way they won't stick around and disturb you.

After all these steps, all you have to do is screw the handles to the drawer. Ready!

How is the frame installed?

The lining cabinet should be mounted on a wooden frame. The frame is performed in the following sequence:

- First you need to assemble the front and rear frames, which involves connecting beams 1.5 and 1.8 m long; metal frames are used for this.

- You can lay plywood on the floor; it acts as the bottom of the cabinet. The beams can be connected without the use of corners; for this you need to use self-tapping screws, the length of which is 60-75 mm.

- The back wall of the cabinet, which is made of laminated chipboard, must be attached to the rear frame with self-tapping screws or a construction stapler.

- The rear frame with the wall is placed against the rear wall, then fixed with anchors; they must be level.

- Inside the cabinet, you need to install guides, on which the shelves should then be laid.

At this point, the production of the frame can be considered complete.

Gift containers

Oddly enough, even the most ordinary item can be beautifully packaged in a beautiful gift box, which can cause a storm of positive emotions in the birthday boy. We can offer to make a wooden box for gifts.

Gift boxes can even be made from wood. It's interesting, unique and presentable. Wood is a durable material. It will be able to serve the hero of the occasion for a very long time, because it will not be thrown into the trash and will become an excellent interior decoration. A very interesting idea is to collect money in such boxes.

We use the remains of the lining correctly

The lining is especially suitable for decorative wall decoration:

- From the remains of such wood, you can build, for example, additions in the form of plinths or planks.

- Pay special attention to their docking.

- Make interesting accents in your interior. Fit many scraps to one size. They should be square.

Paint them white and black. Now choose the most suitable area of the room and arrange it in the form of a chessboard:

Chess design using material.

Note. In addition, you can build completely different compositions, just paint the wood in the desired colors.

A flower pot

Lining allows you to decorate interior elements.

For example, sometimes you can make a work of art from a simple pot:

- Cut out the strips. They don't have to be the same size. Glue them vertically onto an ordinary plastic pot. If one of the rooms has lining as decoration, then such a pot will look great there.

- The remainder can be used in different interpretations, depending on your imagination. For example, small shelves in the form of a ladder are now popular.

Unusual figurines, small flower pots and other little things are placed on them.

Wall decoration

If you wish, you can decorate a nondescript wall with a huge clock:

- To do this, you need a mechanism , usually taken from any quartz watch, and hands. They are taken from there or made independently. Make even sticks from the forcing. Draw a circle of the desired size on the wall.

- Attach the mechanism and arrows in the very center . For the dial, glue the cut out strips with glue or liquid nails.

- Make them in the form of Roman numerals . The bars and circle can be painted in any color, so this versatile watch will suit any interior.

Classic lining is an excellent environmental material. It fits into almost all popular modern interior styles thanks to its natural structure and natural pattern.

Advice. However, do not overdo it and use it selectively and not everywhere, otherwise you will get the effect of a country house or bathhouse.

Planter boxes

Do you have your own dacha? It's hard to imagine your garden without beautiful flowers. How to make wooden flowerpot boxes? This is a very beautiful, unique design. Making a flowerpot from scrap items is very easy and, moreover, very exciting.

We offer a fun version of a flower pot made from old shoes. So, you will give your shoes a new life and decorate your garden. In order to make a unique flowerpot, you will need old shoes and free time.

Follow the instructions:

- Fill the bottom of the shoe with soil and plant the seeds of your favorite plants in it;

- Next, you need to water the flower with warm water and place it near the house;

- To prevent too much water from remaining inside the boot, you can make several holes in the sole;

- To make the flowerpot more interesting, you can paint it in your favorite color.

You can use not only old shoes as a basis. You can also use old sneakers, rubber boots, galoshes and other old shoes.

Regular wooden box

In fact, this is an ordinary rectangular design that is suitable for growing flowers in the country or storing various household items at home.

The advantages of making boxes from wood are due to the fact that it is an environmentally friendly and affordable material, convenient for processing with hand tools.

To assemble such a product you will need:

- boards that will go to the bottom and walls;

- fastening elements: screws, nails, metal corners;

- tools: screwdriver, hammer, wood saw;

- roulette;

- a simple pencil and paper to prepare a drawing.

First, a drawing is made. A sketch of the finished product is drawn on paper and the main dimensions are determined. The schematic image allows you to accurately calculate the material needed to make the box.

Any boards left over after construction or renovation are suitable as raw materials. The main thing is that the material is of high quality: there should be no signs of rotting or wormholes, otherwise the service life of the box will be short.

The boards are cut according to the specified dimensions. There should be 5 elements in total: side and front walls, bottom. The boards are nailed together; corners can be placed at the joints to provide additional rigidity to the structure. If the box is intended to be used for growing flowers indoors, it makes sense to lay a layer of waterproofing made of plastic film on the bottom.

Why exactly a tree?

Wood is the very material that is most often used to create products for the home. The reasons why this happens are simple. First of all, it is important to say that wood is an environmentally friendly material that does not pose a danger to human health . It does not emit an unpleasant odor and does not release any toxic substances into the air, so you do not have to worry about allergies or health problems.

Wood is easy to work with

Wood is also one of those materials that you can easily work with at home. You don’t have to use complex specialized equipment; it’s enough to have a sawing tool, drill and screwdriver or screwdriver on hand. Also, grinding and other processing of the material may require a minimum of cost and effort.

The wood is durable and beautiful and, varnished, can maintain its appearance for many years. Only uncoated material can darken over time and lose its former natural beauty. Fresh wood looks very nice.

Why wood is the best material for making boxes

It is not surprising that wood has been and remains one of the most popular types of materials. Although now in almost any specialized store you can buy its derivatives - plywood, panels, furniture board, etc. But none of these options, in any case, will be better than ordinary natural fresh board.

Flower box for balcony

The general principle of making a flower box from wood with your own hands remains unchanged, but the specifics of use force you to take into account a number of nuances.

Depth is of particular importance. Experienced gardeners do not recommend making walls more than 20 centimeters high. Flowers need to be watered regularly, and wet soil significantly increases the weight of the structure.

Balcony boxes need to be placed on a solid base to prevent them from falling down. For these purposes, metal frames welded from reinforcement bars are usually used. The advantage of this method of fastening is that the outdoor box can be easily removed and brought into the house for the winter.

Note! If painting is planned, it is better to give preference to natural and neutral tones. Bright colors not only fade quickly in the sun, but also hide the natural beauty of plants.

To save on decoration costs, it is recommended to plant flowers in two rows. In the foreground there will be climbing plants that will disguise the wooden container. The flowers of the main composition are planted in the background.

Assembling a wooden box

The entire assembly process is very simple, no tricks or hidden mysteries. We take the most ordinary nails 5 by 0.15 cm. Why thin nails? So that the structure is tightly fastened and the boards do not crack.

First, we nail the top and bottom strips from the end, then we place the remaining wooden blanks. We screw 24 cm long planks to the wooden base from below, use 35 mm self-tapping screws.

Drawings and dimensions of wooden boxes are presented below.

Plywood structures

Here the material is selected depending on the intended use of the finished product. If the box is intended for correspondence, you can get by with thin plywood. For seedlings or flowers, multilayer sheets impregnated with a waterproof compound are more suitable.

The design is made according to the following scheme:

- make a drawing of the box with dimensions;

- the drawing is transferred to a sheet of plywood;

- parts are cut out according to the markings;

- individual elements are fastened together with self-tapping screws or nails, and the joints are treated with sealant.

Considering that plywood is easy to process, you can make more complex, non-standard country boxes. For example, the joints of the walls should be designed according to the tongue-and-groove principle. If you are making a deep box for storing children's toys, you can attach wheels from an old computer chair to the bottom. Drawers with a sliding top panel look interesting. Here a cover is cut out of a sheet of thin plywood and a groove is cut in the upper part of the walls.

general information

A box is a type of container or an interior item, which is a product that has a cubic or parallelepiped shape. It can be made of various materials, including plastic, cardboard, metal, but is mainly made according to tradition from wood or its derivatives. Depending on the design, the box can have solid walls and bottom or slatted surfaces, and it can also have a lid and be either simple or decorative.

On a note! The category of drawers also includes drawers that complement furniture and make it more functional and convenient to use. Such boxes usually do not have a top lid, but their bottom is equipped with special wheels that ride on small rails fixed inside the cabinet or cabinet in the place where the box itself should be located. This makes it easier to use.

Wooden box

The history of the box itself is unknown. From time immemorial, people have used various containers for storing all kinds of household items, transporting and packaging goods, etc. Historians believe that, most likely, the first boxes appeared during the period when trade relations began to develop and were invented precisely with the aim of simplifying the transportation of goods and products , maintaining it in proper quality until it reaches the point of sale.

Wooden vegetable boxes

Nowadays, a wooden box is still used for transporting and storing goods, but at the same time it is also used in everyday life, and even in gardening. It is actively used for harvesting and growing seedlings. By the way, at one time standards even appeared for boxes for potatoes, storage of apples, etc.

At the same time, the boxes settled firmly in the house. They can be used not only as furniture elements, but also as individual products. For example, there are drawers for storing tools, small parts, sewing accessories, etc.

DIY wooden box

Serious competitors to a regular wooden box are products and containers made of veneer, plastic, and cardboard. But none of them can fully replace simple, but reliable and high-quality boxes, and therefore they continue to be actively produced and made with their own hands.

For seedlings

The size and shape of wooden planting boxes will depend on how you grow your flowers. Bulky items take up a lot of space and spoil the overall interior of the apartment. Therefore, if you plan to grow cucumbers and tomatoes on a windowsill, it is better to limit yourself to small wooden plywood boxes.

A garden plot offers more opportunities for the DIYer. So, a large and functional box for seedlings can be made from an old pallet. In fact, a pallet initially represents a finished product. The gardener can only make the bottom and walls from pieces of multi-layer plywood. To do this you will need decorative nails and a hammer. After this, the internal space is filled with earth, the seeds are sown between the top rows of boards.

Step-by-step manufacturing instructions

The box can be made in 1–1.5 hours. The work includes the following steps:

- The prepared area is covered with film or other protective material so as not to damage the floor.

- A product design with dimensions is drawn on graph paper. It is advisable to draw an axonometric projection.

- Boards and beams are cut and parts of the required length are cut with a hacksaw.

- The corners of the parts are sanded with an emery sponge or paper.

- The bottom is made from timber and slats: two stiffening ribs are placed and the strips are screwed in with self-tapping screws, leaving no gaps between the elements. The bottom can also be made of plywood, a piece of fiberboard or chipboard.

- The side walls are assembled from planks and bars (using self-tapping screws) and connected in series.

- The finished container is varnished, painted with oil paint, and drawings are applied according to a template or painted. The toy box is ready.

It is better to polish the boards and bars before assembling the box, since it is difficult to polish the finished product. And burrs left in hard-to-reach places in the container can injure children's skin.

Making a plant box

Step 1. First of all, you need to decide on the dimensions of the box being constructed. It is important to choose the place where it will stand. Based on this, you should sketch out a drawing of the box indicating the dimensional parameters and calculate how much material is required.

First you need to decide on the sizes

Step 2. Next, you need to go to the store and purchase everything you need. First of all, you need to buy the required amount of boards.

Buy boards in the required quantity

Step 3. Now you need to apply the appropriate markings to the board - mark the sides and ends of the box on it. It is better to take measurements with a tape measure, but to get even marks it is better to use a square.

Marking

Step 4. Next you need to assemble the box frame and drill holes in its sides. It is better to make several holes on each side.

Assembling the drawer box

Step 5. The boards on the sides of the box need to be connected together using self-tapping screws. You can also use nails, but connections with self-tapping screws are much stronger and of better quality.

Self-tapping screws are used for connection

Step 6. Next, you need to determine the size of the bottom of the box and cut the bottom itself from the board. It needs to be secured by drilling wooden holes and screwing screws along the bottom border of the box around the entire perimeter.

Attaching the drawer bottom

Step 7: It is important to be sure to drill a few drainage holes in the bottom of the plant box. They will ensure the drainage of excess water that will enter the soil during irrigation or rain.

Drainage holes are drilled

Step 8. It is important to sand all surfaces of the drawer so that they are smooth, pleasant to the touch and safe.

Sanding the drawer

Step 9. Finally, the box can be painted, but it is better to coat it with varnish. This will make the box beautiful and additionally protect it from moisture.

Finished product painting

Decorating boxes

Wooden gift boxes can be decorated in many ways, we will tell you about the most popular options. Each of them is good in its own way and it is better to choose based on the purpose of the product.

Box sizes.

Wooden containers for storing food cannot be treated with synthetic varnishes, stains and impregnations; there are other compositions for this.

- If you want to highlight the natural pattern of the board, then the box can be tinted with a solution of potassium permanganate.

- In order to protect the wood and at the same time leave it in its original appearance, the board is coated with linseed oil.

- A noble golden hue will appear if you treat the surface with beeswax mastic. The mastic recipe is simple: 4 parts refined linseed oil and 1 part wax are heated in a water bath and mixed.

Polished boxes.

Decoupage of a wooden box can be recommended to people who want to make their product original or give new life to an old box.

The technology here is simple, but requires patience.

- First, the product is covered with primer, which most amateurs use PVA glue for. But craftsmen recommend mixing chalk with NC varnish to a liquid, creamy state and covering the wood.

- When the soil dries a little, the drawing itself is glued onto the damp base. Now every transition sells pictures on rice paper for decoupage, so there is plenty to choose from.

- After the base is completely dry, the box is covered with 2 layers of acrylic varnish and 3-4 layers of polyurethane or nitro varnish are applied to it. Before applying a new layer, you need to let the previous one dry.

Decoupage on the box.

Important: fire-hazardous structures, for example, such as an external junction box designed to look like wood, are decorated only with water-dispersed varnishes and paints. It is best to use acrylic-based compositions.

You can artificially age a product using the craquelure technique. The retail chain now sells ready-made crack kits. The technique itself is simple: a thin layer of craque varnish is applied to a raw, recently painted surface, which shrinks as it dries, thereby forming a network of small cracks. After drying, the product is coated with a protective layer of furniture varnish.

Craquelure technology.

The video in this article provides additional information on the topic.

Drawer

How to make a drawer? Buy:

- wood processing machine;

- roulette;

- construction corner;

- unedged board 2.5*25*130 cm.

You will also need a hammer and nails. And also 4 wheels from a children's toy stroller and attachments to them.

Procedure:

- We convert unedged lumber into edged lumber.

- We cut the board into several pieces - four of 20 cm and 1 of 24 cm.

- We process blanks.

- We cut the remaining boards to a width of 4.5 cm along the grain of the wood.

- We collect the box.

- We attach wheels to the bottom.

Slat box

Step 1. First of all, you need to cut the blanks to create a box. You will need bars of the selected length, slats 1 cm thick. The bars need to be cut to length so that their profile is triangular.

Blanks are cut

The process of creating blanks

The block has a triangular cross-section

Step 2. Next you need to take the bars, lay them on top of each other (2 bars on each side) and start making walls. You need to apply wood glue to the flat surface of the block and arrange the slats so that they rest on the flat side surface of the bars. The slats are placed at a certain distance from each other to create gaps.

Applying glue

The slats are parallel

Advice! If you plan to make several boxes of the same size, then it is convenient to use a wooden template to create the walls.

Step 3. Then the slats additionally need to be secured to the corner bars using nails or self-tapping screws. In this way, two side walls of the box are made.

Additional rail fastening

Finished side wall

Step 4. Next, the prepared walls need to be placed in a special template (or simply held correctly) and, using the same principle as in steps 2 and 3, attach the next slats to the sides of the free sides of the bars. Thus, it will be possible to create two other side walls.

The next slats are attached

All side walls are ready

Step 5. Then the bottom is made. You need to lay two slats (with a length equal to the length of the box) parallel to each other, and fix other slats on them, but without gaps, so that the bottom is solid.

Making the bottom of the box

The bottom turns out to be solid

Step 6. All that remains is to secure the bottom to the underside of the box, and it is ready. If necessary, all structural parts can be sanded before assembling the box. It is better to varnish or paint the product after assembly.

The bottom of the box is attached

This is what the finished box looks like

Application of pallets

From several pallets you can make a deep wooden box with an opening lid for growing garden crops in a greenhouse. To do this, the pallets are carefully disassembled into their component parts, nails are removed, and damaged boards are discarded.

The boards are cut to size based on the future shape of the box: rectangle or square. For the racks, 4 square bars are cut, their length depends on the height of the box.

The boards that will go on the side walls are laid in a row and a straight line is drawn at a distance of 15-20 mm from each edge. In accordance with the markings, apply a block and tighten the screws. The result should be two longitudinal walls. In order to subsequently equip the box with an inclined lid, the top board of one of the sides must be shortened by 3-5 cm.

The finished panels are installed in parallel, and the end boards are attached to the support bars. After this, the bottom is made from plywood. If the seedlings are grown outside, the lower element of the structure can be neglected.

The lid is made of a slatted frame corresponding to the size of the box. The elements are fastened together with flat metal corners. If the box has a large area, it is better to strengthen the lid with two longitudinal slats. Using a stapler, plastic film is nailed to the surface of the lid. 2-3 loops are attached to the back of the wall.

At the final stage, all wooden elements are treated with a special disinfectant composition to prevent rotting and the appearance of bark beetle larvae. For ease of use, the sides of the lid can be supplemented with window latches that will hold it in the half-open position. Now all that remains is to fill the box with soil and plant the seeds.