For smoking meat and fish, installations are used, each of which has a chamber for food - a smoking cabinet. It is called that because of its external similarity: most of these designs are a rectangular container with a side door. At home, you can make a smoking cabinet with your own hands according to our drawings.

The smoking cabinet is even made of wood

Stainless steel cold smoking cabinet

The best material for a smokehouse is food-grade stainless steel sheet with a thickness of 1.2-2 mm. It is not subject to corrosion and is easy to clean.

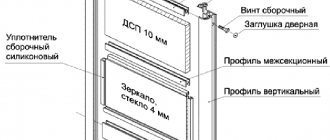

The design of a stainless steel smoking box is similar to a smoking cabinet from a refrigerator or a metal safe and is assembled from rectangular pieces of the required size:

- two pieces 500x500 mm for the bottom and ceiling;

- two pieces 1200x500 mm for the sides of the camera;

- two pieces 500x1200 mm for the back wall and door.

The smoking cabinet is assembled with your own hands using electric welding. For a better fit of the door and installation of grilles, stainless steel corners are welded to the walls. A hole is drilled in the bottom of the box to attach a smoke generator.

The drawing shows the dimensions of such a structure.

Cold smoking cabinet

Where is the best location?

It is very important to find the right place for a stationary smoker: this is not a small, portable structure that can be stored at home or in the garage and taken out when needed.

When choosing a location, it is worth remembering that a large amount of smoke will come from the smokehouse, which should not enter the living quarters in the country house. In addition, harmful substances can harm trees and other green spaces. Therefore, choosing the ideal place on the leeward side will be quite difficult, and for each house it is purely individual. The resulting products can be stored in the cellar, as long as the room is dry and cool.

Sausage smoking cabinet

Homemade sausage is smoked in a suspended state, in rings. These rings are put on a wooden stick. Every hour during hot smoking and every 5-6 hours during cold smoking, these rings must be turned over. Therefore, it is more convenient to smoke sausage in a cabinet with a removable top lid.

Important! Sticks for hanging sausages should be made of hardwood and well dried.

Cabinet for smoking sausages

How to use it correctly?

Before placing food in the smoking unit, it is worth preparing them. If you take fish for smoking, it should be gutted and soaked in brine, for which you take a glass of salt per 4 kg of fish. Horse mackerel or mackerel is rubbed with salt and wrapped in cling film, pressed on top with a lid and kept for two days. The fish is then dried for two hours, cooled and placed on a smoking rack. The fish is smoked for one to three hours depending on its size.

To prepare delicious juicy meat, the product should be pre-salted. If the pieces of meat are large, they should first be boiled and then placed in the device. The same method is used when smoking homemade sausage. The meat is simmered in the device for 2–6 hours. To reduce the cooking time of meat, you can rub it fresh with salt. Any product should be simmered until it is completely cooked, since repeated treatment with smoke makes the food inedible.

The ambassador of products can be as follows:

- dry;

- wet;

- mixed.

With the dry method, the shelf life of the product can be extended to two weeks. In order to get juicy and tender meat, you should use a wet or mixed cooking method.

Fish smoking cabinet

A smokehouse for smoking fish is no different from other similar devices, except for one feature. Fish is a delicate product; when overheated, it dries out, loses fat and becomes boiled rather than smoked.

Therefore, when smoking it, it is necessary to control the temperature in the chamber, preferably on each tier of grates, and, if necessary, reduce the heat or the processing time.

Scheme of a cabinet for smoking fish

Preparation

Initially, everything should be prepared for work. Conventionally, this moment can be divided into several stages.

Fuel preparation. It consists in choosing sawdust or wood chips. It is highly not recommended to use sawdust from pine wood, as when smoked the product will acquire a bitter taste

It is worth paying attention to such options as alder, pear, apple, which can be found on sale. The color and smell of the products may differ depending on the choice of fuel.

Rosemary sprigs, almond shells and other herbs with a pleasant smell are often added for a piquant aroma. During smoking, you can use both wet and dry wood chips; the former produce more smoke, while the latter are the classic option. The disadvantage of wet wood chips is a large amount of burning, which is compensated by installing a special grill or using a damp cloth. It is strictly not recommended to use painted material or material coated with varnishes or other chemicals.

Smoking cabinet from the refrigerator

The easiest way to make a home smoker is from the refrigerator. Its design depends on what type of device the resulting device will be used for - hot or cold smoking.

Advice! It is best to use Soviet-made refrigerators with wire grilles

Cold smoked smokehouse

For a cold smoked smokehouse, smoke is produced using a smoke generator. With this type of processing, the temperature does not exceed 50°C, so all plastic parts can be left:

- Remove the shelves. It would be better if they were made of wire, like in old Soviet-made refrigerators.

- In a single-chamber device, remove the freezer and wires. In a two-chamber cooler, it takes up little space, so you can leave it.

- Seal the resulting holes. Wooden or plastic plugs are suitable for this.

- Cut a hole on the side or back at a height of 10 cm above the bottom for the incoming chimney. Place the refrigerator body on the stand so that the smoke channel slopes upward at a slight angle. Another hole for escaping smoke is made in the ceiling of the smoking cabinet.

- Place a tray at the bottom to collect fat. A disposable baking dish is suitable for this, or simply line the bottom with aluminum foil.

- Install gratings at the required height in the grooves of the housing. If desired, a hole is drilled in the housing and a thermometer is installed.

Diagram of a cold smoked smokehouse from a refrigerator

Hot smoked smokehouse

Converting a refrigerator into a hot smoker is more difficult. This process takes place at temperatures from 50 to 120°C, so the device is subject to modification:

- it is necessary to remove all non-metallic parts - plastic sheathing, thermal insulation and sealing rubber in the door;

- seal the resulting holes in the body with wooden plugs, and replace the elastic band with a felt strip;

- Screw metal corners for grates and a tray for collecting fat to the walls at the desired height, as well as at a distance of 10 cm from the bottom;

- Place the smoking cabinet on a brick stand.

The smoking process is carried out in the same way as in other hot smoking devices:

- sawdust is poured onto the bottom;

- a tray is placed on the lower pair of corners, and food is placed on the upper racks;

- A small fire is lit under the bottom.

The fire heats the sawdust, it smokes and smokes meat and fish.

Diagram of a hot smoked smokehouse from a refrigerator

What can you cook

With the help of a smoking cabinet, regardless of what material it is made of, you can smoke a wide variety of products.

As a rule, meat and fish, a variety of sausages, and chicken are selected for processing. You can even cook vegetables and your favorite fruits using the device. It is very important that all products are properly prepared. Otherwise, the smoked meats will not turn out tasty. Meat and fish must be marinated for some time. Don't forget to have enough salt.

If the smoking cabinet is made correctly and equipped with additional elements, then smoking a variety of products will be very easy and simple. In this case, you can follow the chosen recipe without any problems, and then the smoked meats will turn out even tastier than those that can be purchased in the store.

It is not necessary to buy a factory-made smoking cabinet.

You can make it yourself at home. For this purpose, available materials and a minimal set of tools are suitable. As a supplement, you can use diagrams and drawings presented on the Internet.

Wooden cold smoked smokehouse cabinet

A stationary smoking cabinet can be made of wood. It is better to use deciduous wood, otherwise before starting operation you will have to dry smoke it several times, without products, so that the walls are saturated with smoke. For home use, a chamber measuring 0.5 x 0.5 x 1 meter and a smoke generator with a capacity of 3 liters is sufficient for 100 kg of products. The smoking process continues for a day. If there are no boards, then you can build a similar stationary smokehouse from brick

Structurally, such a wooden smokehouse is similar to a box with a door or a country “house of an unknown architect.” It is assembled on a frame made of 40x40 mm bars. Guides for the gratings are made from the same bars. The frame is covered with boards or plywood.

It is best to make the walls of the box from clapboard or floorboard. These lumber have grooves with which the boards are connected to each other. This connection is tight enough to prevent smoke from escaping.

If there is no lining, then it is permissible to make a smoking box with your own hands from boards. In this case, when assembling the cracks, it is necessary to seal them with tow or other sealant.

A good result is obtained by sheathing the walls with plywood. There are no cracks in the walls of this material, but under the influence of moisture the plywood warps and delaminates. Therefore, after each use, the plywood cold smoking box must be dried and the outside painted with waterproof paint.

Such a smoking cabinet can be built from logs. The resulting structure will look like a wooden hut. A sealant is laid between the logs.

On a note! In a log structure, the door is still made of planks.

The door in the box for cold smoking is made with your own hands, assembled from several longitudinal boards and two transverse ones. A plywood door is simply a piece of plywood of the required size.

The door is attached to two hinges and has a rubber or felt seal along the contour.

The roof is made of a single or double slope. Single-pitch is simpler. To make it, just bevel the top of the side walls and make the back wall smaller than the door. A chimney is installed in the roof.

The smoke generator is placed on the ground; if necessary, a chimney is laid in a recess or instead of it in the ground, at the other end of which there is a firebox, and the smoking cabinet is made without a bottom.

Wooden smokehouse cabinet

DIY assembly

Smoking cabinets designed for cold smoking are best made from high-quality wood. You should not use layered materials that will be treated with adhesive impregnation. Due to the use of wood, finished smoked meats will have a special aroma and taste. The ideal option would be alder, aspen, linden or any other hardwood.

Schemes and drawings

There is a huge selection of diagrams and drawings on the Internet for different design options. You can choose exactly the option that is ideal in a particular case, taking into account the operating conditions, the amount of products that will be smoked, and other things.

Required tools and materials

To speed up the assembly process, in addition to wood, you need to prepare other tools and materials.

- Hacksaw, hammer and nails;

- The bars that will be used to build the frame;

- Hinges, handle, bolt or bolt;

- Tow or special sealant;

- Roof material;

- Grids and hooks for food;

- Chimney pipe.

Frame

In order to make the body of the smoking cabinet, you need to fasten four long bars together. They are fastened from below and from above. In order to give the structure stability, several additional crossbars are made. In the future, grates with products will be installed on them.

The frame is sheathed with boards that fit together as closely as possible.

All joints are treated with sealant or tow.

Cabinet doors

The door must be large enough. It is installed in the front part of the structure. The width of the door can be the same as the width of the wall. It is made from boards that are joined as tightly as possible so that smoke does not escape through them. A handle and a latch are attached to the door. The entire perimeter of the door must be treated with a sealant. The ideal option would be exactly the same rubber band that is used on refrigerator doors.

Chimney

The chimney is made from an ordinary metal pipe with a sufficiently large diameter or from wood. The second option can only be used if the design will be used exclusively for cold smoking of products.

Installation of gratings

The grilles are installed last.

It is also necessary to install a tray, baking sheet or other metal container in the smoking cabinet into which fat from the processed products will drain.

At the very top of the smoking cabinet there may be several additional crossbars on which you can also hang food using hooks.

Smoking cabinet with smoke generator

In cold smoking devices, smoke is not produced in the chamber, but separately, in a smoke generator. It is placed below the smoking cabinet and the smoke, passing through the chimney, is cooled.

Advice! To improve the quality of smoke, the chimney is equipped with a condensate collector, filter, refrigerator and other accessories.

Diagram of a smoking cabinet with a smoke generator

Heated cold smoking cabinet

The cold smoking process takes place at a temperature of 20-50°C. But if it’s cold outside, then the smoke coming into the smoking cabinet has a lower temperature. To heat the smoking chamber, an electric stove or several incandescent lamps are installed inside it at the bottom.

Advice! For a more stable temperature, the lamps are turned on via a thermostat, for example, from an incubator.

Scheme of a heated smoking cabinet

Useful improvements

In order to make a wooden smokehouse more convenient to use, you can additionally make several more elements.

Drovnitsa

In order to store firewood next to the structure, it is enough to make a firewood shed. To do this, one of the sides of the roof is stretched and placed on special supports. Additionally, the place for firewood can be fenced off.

Temperature sensor with thermometer

With their help, you can easily control the smoke temperature and cook smoked meats, exactly following the chosen recipe.

Electric cold smoking cabinet

Several companies produce electric smokers for homes and small businesses. In these devices, sawdust is heated in a smoke generator by electric heaters, there are built-in fans that blow smoke over smoked meats, thermostats and other devices. How to use the smokehouse is indicated in the manufacturer's instructions.

These cold smoking cabinets do not require an open fire for heating, but do need to be connected to a ~220 V network. The smoking process occurs at lower temperatures and longer than in hot smoking devices.

You can make such a household device yourself from a metal box and install it on the balcony.

All controls in an electric smokehouse are installed in the control panel, which is mounted on the wall of the smokehouse.

Components of an electric smoking cabinet

Drawings and models

Below we provide drawings and models for making smokers (smokers) with your own hands. You can also contact companies that will manufacture the product to order. You just need to provide the drawing (model) file.

Drawing of a large grill-smoker-smoker in PDF and SLDPRT format

Drawing of a smokehouse with a lid-house and a water seal in DXF and CDR format

Drawing of an octagonal smoker-smoker in STP, IPT formats

Drawing of a simple smokehouse with a water seal in PDF format

Drawing of smokehouse No. 1 with a water seal in DXF, PDF, KOMPAS formats

All drawings of smokehouses

Universal smoking cabinet

Before choosing a smoker, you need to determine the necessary features. But there are “wide-profile” devices

They can process products in different modes, so it is equipped with an external smoke generator with a cooler, a built-in heating element at the bottom and an exhaust regulator at the top.

Different elements operate in different modes:

- Cold smoking. Smoke generator with cooler and exhaust fan.

- Hot smoking. Internal heating element on which a container with sawdust is installed.

- Drying. During normal drying, only the exhaust fan works, and during accelerated drying, a heating element is added to them.

Advice! For better performance, it is advisable to equip all electrical appliances with a power regulator and insulate the housing.

Components of a universal smoking cabinet